You might find a cut to length line in a factory. Workers use it to change big metal rolls into flat sheets. This machine grabs the metal coil and makes it straight. Then, it cuts the metal into the right sizes. Many industries use this process when making things. It helps you get perfect sheets fast. You can trust this system for good speed and exact results.

Key Takeaways

A cut to length line changes big metal rolls into flat sheets. It makes sure the sheets are the right size for many industries. Using this system helps make products faster. It also cuts down on wasted material. This makes the work more accurate and saves money. Important parts like the uncoiler, feeder, and stacker work together. They help the machine run well and make good products. Automation in cut to length lines makes work faster. It lets workers change settings quickly for different customers. Workers must check and fix the machine often. This keeps the cut to length line safe and working well.

Cut to Length Line Basics

What Is a Cut to Length Line

You may wonder what a cut to length line does in a factory. This machine takes large rolls of metal and turns them into flat sheets. You feed the metal coil into the system, and it straightens the material. The machine then cuts the metal into pieces that match the size you need. You can find cut-to-length lines in places that make cars, appliances, or building materials.

A cut-to-length line stands out from other metal processing machines. Here is a table to help you see the main features:

Feature | Description |

Feeding System | Automated system for continuous input of metal materials, ensuring consistent tension and alignment. |

Cutting Mechanism | Uses flying shears or rotary blades for precise and clean cuts tailored to specifications. |

Stacking Unit | Organizes and collects cut pieces for further handling or processing, enhancing workflow efficiency. |

You can see that each part of the cut to length line works together to give you flat, even sheets. This system focuses on making sure every piece is the right size and shape.

Tip: If you need large, flat metal pieces, a cut-to-length line is the best choice. Slitting lines, on the other hand, cut coils into narrow strips.

Main Function and Purpose

The main job of a cut-to-length line is to help you get flat metal sheets with the exact length you want. You can use this system to speed up your work and reduce waste. The cut-to-length line lets you adjust the size of each sheet quickly, so you can meet different customer needs.

Here are some key goals you achieve with a cut to length line:

You increase production speed by using automated feeding and cutting.

You lower costs because the machine reduces material waste.

You improve accuracy, so every sheet matches your order.

You free up workers for other important jobs, since the line handles most tasks by itself.

A cut-to-length line gives you more control over your products. You can make quick changes if you need a different size or shape. This flexibility helps you stay ahead in a busy market. The system also helps you keep quality high, which is important for your business.

When you use a cut to length line, you get flat, clean sheets that are ready for the next step in your process. You save time, use less material, and deliver better results to your customers.

Key Components of Cut-to-Length Line

Uncoiler and Feeder

The process begins with the uncoiler. It holds the heavy metal coil. The uncoiler lets out the coil slowly. This keeps the metal from getting tangled or damaged. There are different kinds of uncoilers. Some are start-stop, flying shear, rotary shear, or heavy gauge lines. Each type is made for a special job. All types help feed the coil smoothly.

After that, the feeder takes the metal. It pulls the metal from the uncoiler and moves it forward. The feeder uses strong motors and smart controls. This keeps the metal moving at the right speed. This step is important for making things exact. The feeder also straightens the metal as it goes. This makes sure the metal lines up for cutting. You get very accurate sheets because the feeder puts the metal in the right spot.

Feature | Description |

Double Operation Units | Make things faster and more exact with strong motors. |

CNC Machined Feed Body | Gives very exact sheets every time. |

Electronic Controls | Help the feeder work smooth and exact. |

Leveler and Shear

The leveler makes the metal sheet flat. When you open a coil, it can have bends or waves. The leveler uses rollers to fix these problems. This step gives you a flat sheet. It stops problems later when making things. The leveler also lowers stress inside the metal. This helps your sheets stay flat and true.

Next, the shear cuts the metal to the right size. There are different kinds of shears. Some are cross-cutting, pendulum, or flying shear. Each kind has its own good points. Flying shears are good for fast work and cutting all the time. Shears help you get exact cuts and keep every sheet the same size.

Stacker and Automation

The stacker picks up the cut sheets and puts them in neat piles. New stackers use automation to work fast and safe. You can stack many sheets at once. This saves time and helps you make more. Automation also helps check quality. Sensors and cameras look at each sheet for size and shape. If something is wrong, the system tells you right away. This keeps your line working well and makes sure every sheet is just right.

Note: Automated stackers help you work faster and switch jobs easily. You finish more work with less effort.

With these main parts, you control every step. You get exact, accurate, and steady results each time.

Coil Cut-to-Length Process

Step-by-Step Workflow

You can follow a clear process when you use a coil cut-to-length system. Each step helps you get metal sheets with the right cutting accuracy and specific length. Here is how the workflow usually goes:

Coil Infeed and Identification

You start by loading the metal coil onto the uncoiler. You check the coil’s details to make sure you use the right material.

De-stacking and Orientation

You position the coil so it feeds smoothly into the line. This step helps prevent jams and keeps the process steady.

Conveying and Pre-Packaging Checks

You move the coil through the feeder. You check for dirt or coating that could affect cutting accuracy.

Inner Protective Wrapping (Optional)

You may wrap the coil to protect its surface if needed.

Main Orbital Wrapping

You apply a main wrap to keep the coil safe during processing.

Edge Protection Application

You add edge guards to prevent damage during cutting.

Coil Strapping

You strap the coil to keep it secure as it moves through the system.

Stacking and Palletizing

After cutting, you stack the sheets neatly. You use a stacker to organize them for easy handling.

Unit Load Securing (Pallet Wrapping/Strapping)

You wrap or strap the stacked sheets to prepare them for shipping.

Final Weighing and Labeling

You weigh the finished stack and add labels for tracking.

Optional Upending

You may turn the stack upright if needed for transport.

Outfeed and Dispatch

You move the finished sheets out of the line and get them ready for delivery.

Data Logging and System Integration

You record all details in the system for quality control and future reference.

Each step in the coil cut-to-length process helps you reach high cutting accuracy and product quality. You can see how every part works together to give you sheets with the exact specific length you need.

Tip: If you want to improve accuracy, pay attention to each step. Small checks and adjustments can make a big difference in the final result.

Here is a table that shows how quality control works at different stages:

Quality Control Mechanism | Contribution to Product Quality |

Standardization of Processes | You reduce mistakes and keep every batch consistent. |

Advanced Inspection Tools | You spot problems early and keep output quality high. |

Non-Destructive Testing (NDT) | You find flaws without harming the metal, keeping sheets strong. |

Safety and Maintenance

You must follow safety rules when you operate a coil cut-to-length line. These steps help you avoid accidents and keep the system running smoothly. Here is a list of safety procedures you should use:

Wear proper work clothes and safety gear before you start.

Check all handles and controls to make sure they work.

Clamp the material correctly and check the leveling equipment.

Measure the center position and hole spacing after loading.

Stop the line before changing speed or making adjustments.

Keep your hands away from moving parts and cutting areas.

Do not place tools or other items on the machine.

Stay focused and do not leave the line while it runs.

Clean the area and turn off the power when you finish.

Lubricate gears and moving parts regularly.

If you hear strange sounds or see a fault, stop the line and check for problems.

You also need to keep up with maintenance to make sure your coil cut-to-length line stays reliable. Here is a table with important maintenance practices:

Maintenance Practice | Description |

Electrical Checks | You inspect wires and test emergency stops to keep controls safe. |

Sensor Calibration | You calibrate sensors often for accurate readings and cutting accuracy. |

Dimension Settings | You set and check cutting dimensions before starting to avoid waste. |

Feeding Speed | You adjust speed for each material to balance quality and efficiency. |

Material Alignment | You align material to prevent uneven cuts and improve cutting accuracy. |

Lubrication and Cleaning | You lubricate moving parts and clean the line to prevent wear. |

Blade Sharpening | You keep blades sharp for clean cuts and replace them when needed. |

Note: Regular checks and cleaning help you avoid breakdowns. You get better cutting accuracy and longer machine life when you follow these steps.

You can trust a coil cut-to-length line to deliver sheets with high accuracy and specific length when you follow the right workflow, safety steps, and maintenance routines.

Types of Cut-to-Length Lines

Light, Medium, and Heavy Gauge

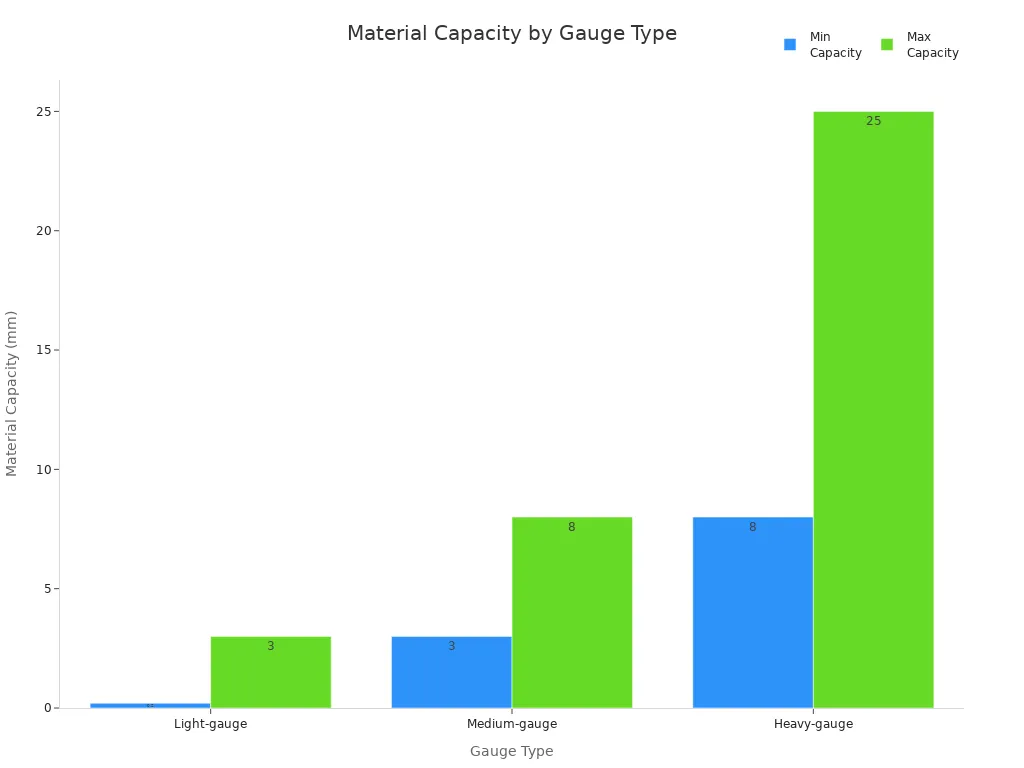

You can pick a cut-to-length line based on how thick the metal is. Each type is made for a different job. Light-gauge lines are good for thin metal. People use them for things like appliances or HVAC parts. Medium-gauge lines work with thicker metal, such as building panels. Heavy-gauge lines are strong and cut very thick steel. You see these in shipbuilding or when making bridges.

Here is a table that shows what each gauge type can do and where it is used:

Gauge Type | Material Capacity (mm) | Application Description |

Light-gauge | 0.2-3 | Good for lots of thin metal, like in appliances and HVAC. These lines use flying shears and can go over 100 meters per minute. |

Medium-gauge | 3-8 | These lines balance speed and power. They are used for construction panels and can handle different metals like aluminum or stainless steel. |

Heavy-gauge | 8-25+ | These lines are for thick steel. They use stretch-leveling to keep the metal flat. You need them for shipbuilding or bridges, where the steel is very strong. |

Many industries use these lines. You find them in heavy manufacturing, construction, shipbuilding, energy, car making, and aerospace. They help companies get the right size metal sheets for their work.

Shearing Methods

There are different ways to shear metal. Hydraulic shears can cut many thicknesses and are flexible. Mechanical shears are faster and work best with thin metal. Rotary shears are good for high-speed lines.

Tip: The way you shear metal changes how fast you work and how smooth the edges are. Hydraulic shears are strong for tough jobs. Mechanical shears are quick for lighter work.

When you cut metal, you might see small bumps called burrs on the edge. These need to be taken off later. A good cut has a smooth middle and only a tiny burr at the bottom. If you check the edges, you can make your products better.

Shearing can make burrs that need more work.

Slitting uses less force, but if the metal is not lined up right, the edges can be rough.

Custom Solutions

Sometimes, you need special features for your line. Custom cut-to-length lines help with hard jobs, like cutting strong metal or odd sizes. These lines can flatten and pack metal for cars or factories. They also keep the surface nice, which is important for many jobs.

Here is a table with some custom services you can use:

You can also find other options like multi-blanking, coil press blanking, and sheet blanking shearing. These help you make special parts, like car pieces or strong building materials. Custom lines can cut thick metal and keep your work steady, even with odd sizes.

Note: Custom cut-to-length lines help you work faster and keep your line running well, even if you have hard jobs.

Applications and Benefits

Industry Uses

Cut to length line systems are used in many places. These machines turn metal coils into flat sheets. They do this with very good accuracy. You can find them in steel mills and metal service centers. They are also in car factories and other equipment factories. These lines help make food and drink machines, electronics, and big machines.

Here is a table that shows where you use a cut to length line and what you can make:

Industry | Primary Products Manufactured |

Steel Mills | Carbon steel, stainless steel, aluminum, copper, brass, tin plate |

Metal Service Centers | Carbon steel, stainless steel, aluminum, copper, brass, tin plate |

Automotive Plants | Carbon steel, stainless steel, aluminum, copper, brass, tin plate |

OEM Factories | Carbon steel, stainless steel, aluminum, copper, brass, tin plate |

Applications | Food and beverage, electronics, heavy earth-moving equipment |

You can use these lines to get materials ready for cars, appliances, and buildings. The system helps you keep up with what factories need today.

Key Advantages

Using a cut to length line gives you many good things. You make your factory work better. You also get more accurate sheets every time. The machine cuts each piece the way you want. This means you do not have to fix as many mistakes.

Here are some key advantages:

Cut to length lines help you waste less material. You cut pieces to the right size, so you save money and help the planet.

You work faster because the machines are automatic. This lets you make more things in less time.

You spend less because you use less material and need fewer workers.

You get very exact cuts, so your products are better.

You can use these lines for many jobs, like making cars or electronics.

Tip: When you use a cut to length line, you work faster and make better products. This helps your business stay strong.

Advantage | Description |

Waste Reduction | You use less material, which saves money and helps the earth. |

Improved Precision | The machine cuts pieces to the right size every time. |

Versatility | You can use these lines for many kinds of products and industries. |

You can see that cut to length lines help you work faster and get better results. These machines make your job easier and your products more reliable.

A cut to length line changes metal coils into flat sheets that are the right size. This machine helps you work faster and make less waste. The sheets you get are very good quality. Many factories use these lines to do better than others. Here are the main reasons why:

Benefit | Why It Matters |

Precision and Accuracy | You always get the right size sheet. |

Efficiency | You can finish your work more quickly. |

Cost Savings | You use less metal and save energy. |

New technology makes these lines even smarter and easier to use. If you want your factory to do better, you should think about getting a cut to length line.

FAQ

What materials can you process with a cut to length line?

You can process steel, aluminum, copper, and stainless steel. These machines work with many metals. You choose the right line for your material thickness and type.

How do you keep sheets flat and accurate?

You use a leveler to remove bends and waves. Sensors and controls help you get the right size every time. Automation checks each sheet for quality.

Is it safe to operate a cut to length line?

You stay safe by wearing protective gear and following safety steps. You check controls before starting. You keep hands away from moving parts. Regular maintenance helps prevent accidents.

Can you adjust the sheet length for different jobs?

Yes! You set the length on the control panel. The machine cuts each sheet to your chosen size. You can change settings quickly for new orders.

Why should you use automation in cut to length lines?

Automation helps you work faster and reduces mistakes. You get better quality and save time. Automated stackers and sensors make your job easier.