1. 5T Hydraulic Decoiler: one set

Automatically control steel coil inner bore shrinkage and stop,

With an electric control cabinet

Max. feeding width: 23.6inch(600mm),

Coil ID Range: 18.8-21.2 inches (508+/-30mm).

Max capacity: 11023Lbs(5 tons), No feeding power, hydraulic motor : 2.2KW

2. Feeding guide device(with leveling roller)

A left and right guiding device at the main entrance of the machine. During work, Raw materials on both sides of the plate enter into the machine by the left and right guiding devices, make the raw materials, and roll forming system to maintain the correct position. The guiding position can be adjusted by the manual screw mechanism, and the left and right can be adjusted independently.

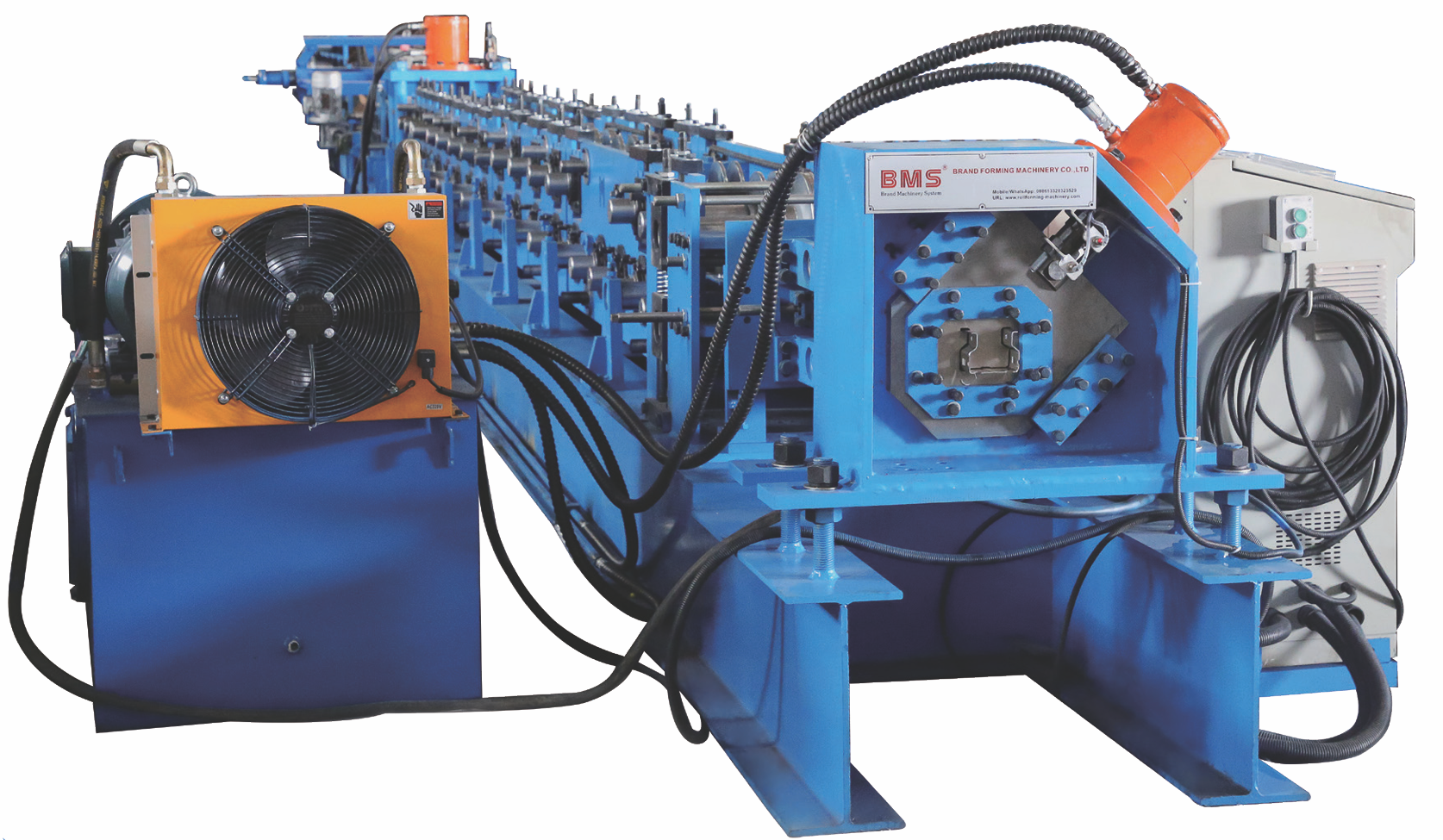

3. Hydraulic Punching device

1)With Four Sets of punching mould

2)Hydraulic motor: 11kw, Hydraulic pressure range: 0-16Mpa

3)Punching tool material: Cr12Mov=D2 (with at least one million times of punching life), Heat treatment to HRC58-62 degree

4)One Cylinder for punching the holes

4)The cutting power is provided by the main engine hydraulic station.

4. Roll forming system

Roll forming system is composed of a machine frame, transmission parts forming roller group, etc.

1) Body frame made from H450 type steel by welding by welding with beautiful appearance, natural aging treatment, and SR(stress relief) treatment.

2)Side wall thickness: Q235 t18mm

3)Roller wheel adopts GCr15(=534A99), Heat Treatment,HRC58-62

Shafts Diameter=ф75/60mm, precision machined

4) Chain: ZIQIANG (by China TOP 1 brand DONGHUA Group)

Chain size: one inch with 18 teeth

5)Adjusting the upper and lower roll gap by hand screw, to adapt to the plate with different thickness

6)Gear/Sprocket driving, about 18-step to form

7) All the screw bolts with grade 8.8(cheap factories use low grade 4.8) to ensure fix the machine structure tightly and long life during the machine's long time running

8)Main motor:15KW;

9)Real forming speed:12-16m/min

5. Hydraulic cutter(Four Cutting Moulds)

1)The cutting system consists of a cutting machine frame, cutter die cutting cylinder, etc.

2)Cut after roll forming, stop to cut; Cutting tool material adopts Cr12Mov=BD2(with at least one million times of cutting life) ,Heat treatment to HRC58-62

Quick blade change, Three-unit blade

3) The cutting power is provided by the main engine hydraulic station.

6. Electronic PLC control system

1)Using PLC control technology, and variable frequency speed regulation technology, to

realize the automatic production of the whole machine.

2) The system provides a friendly man-machine interface and can set the batch, the length of the work piece, quantity, etc.

3)Operate mode: Touch screen + button.

4)Encoder count, with counting numbers and counting length function.

PLC: Delta(Taiwan brand)/ Schneider/Siemens

Inverter: Delta(Taiwan brand)/ Schneider/Siemens

7-inch Color Touch Screen: WEINVIEW(Taiwan brand)/ Schneider/Siemens

8-Encoder: KOYO / OMRON (Japan brand)

Switch bottom, Indicate light, Power supply, Intermediate relay, AC contactor,

Thermal relay: Schneider Electric

Air Switch: LG-LS(Korea brand)

Cut-to-length tolerance≤±1mm

Control Voltage 24V

7. Exit rack 一3m*2sets

Exit rack, used to support the finished product. Length 3 meters.