You use a cold roll forming machine by putting a long metal strip into it. The machine uses rollers to shape the metal at room temperature. This way, you get the same shapes every time and can make many pieces quickly.

Key Takeaways

Cold roll forming machines bend metal strips at room temperature. This makes products that are strong and exact.

These machines work fast. Production speed ranges from 5 to 100 meters per minute, depending on profile complexity and material thickness, ensuring high efficiency for mass production. They do not stop between steps.

Cold roll forming makes little waste. Scrap rates are only 1-3%. This helps save money and materials.

Cold roll forming can make many shapes and profiles. It works with different metals like steel and aluminum.

Operators use a PLC control system to change settings. They can set the length, batch size, and punching details. This makes production more flexible.

It is important to do regular maintenance. Workers should check oil levels and clean the rollers. This keeps the machine working well.

Buying a cold roll forming machine needs good planning. You must think about the first cost, setup time, and if the materials will work.

Safety is integrated into machine design, including emergency stop buttons, safety guards, and photoelectric sensors to prevent accidents, compliant with CE and ISO standards. They must follow the rules when using cold roll forming machines.

What Is a Cold Roll Forming Machine

Definition and Function

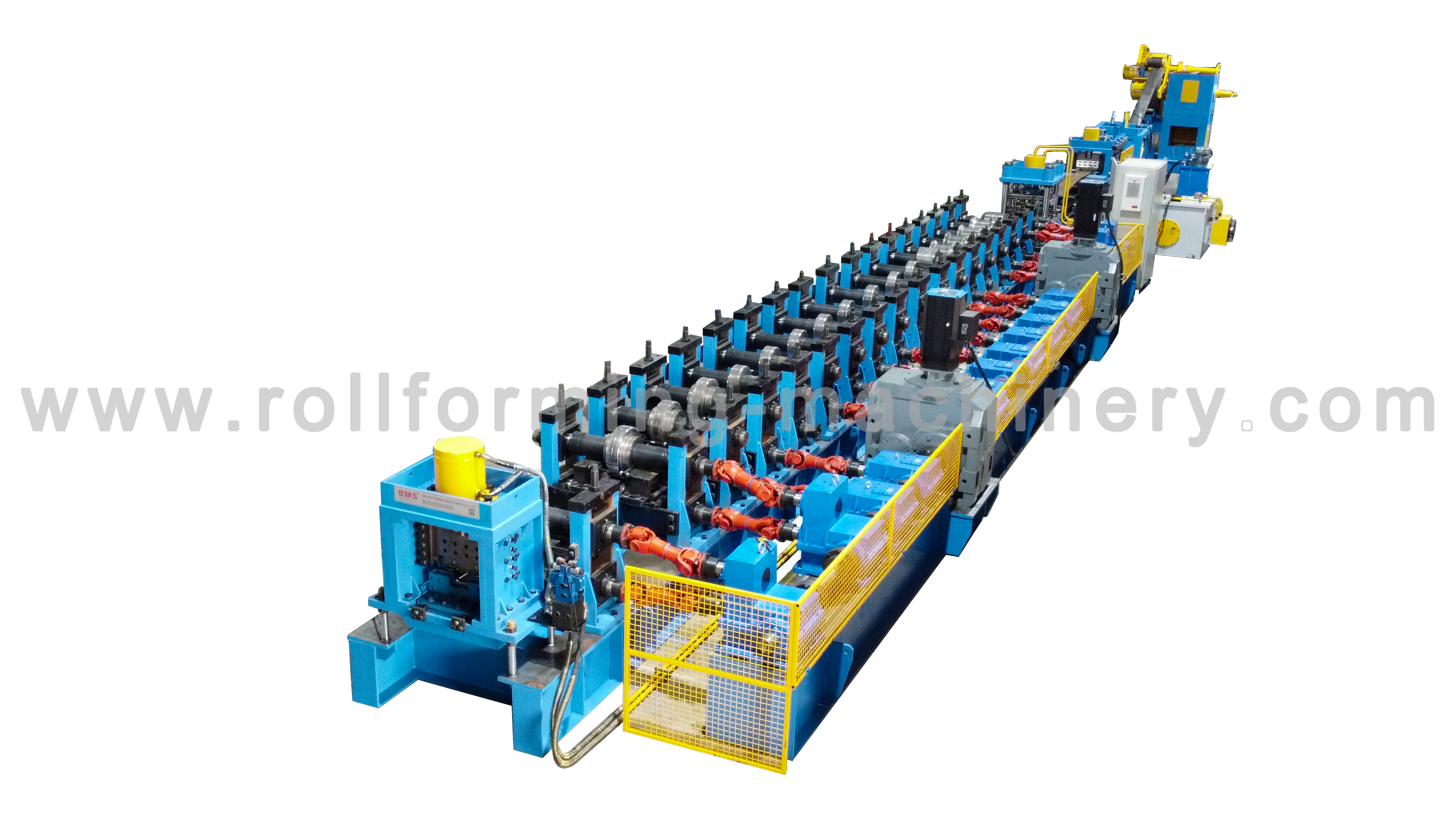

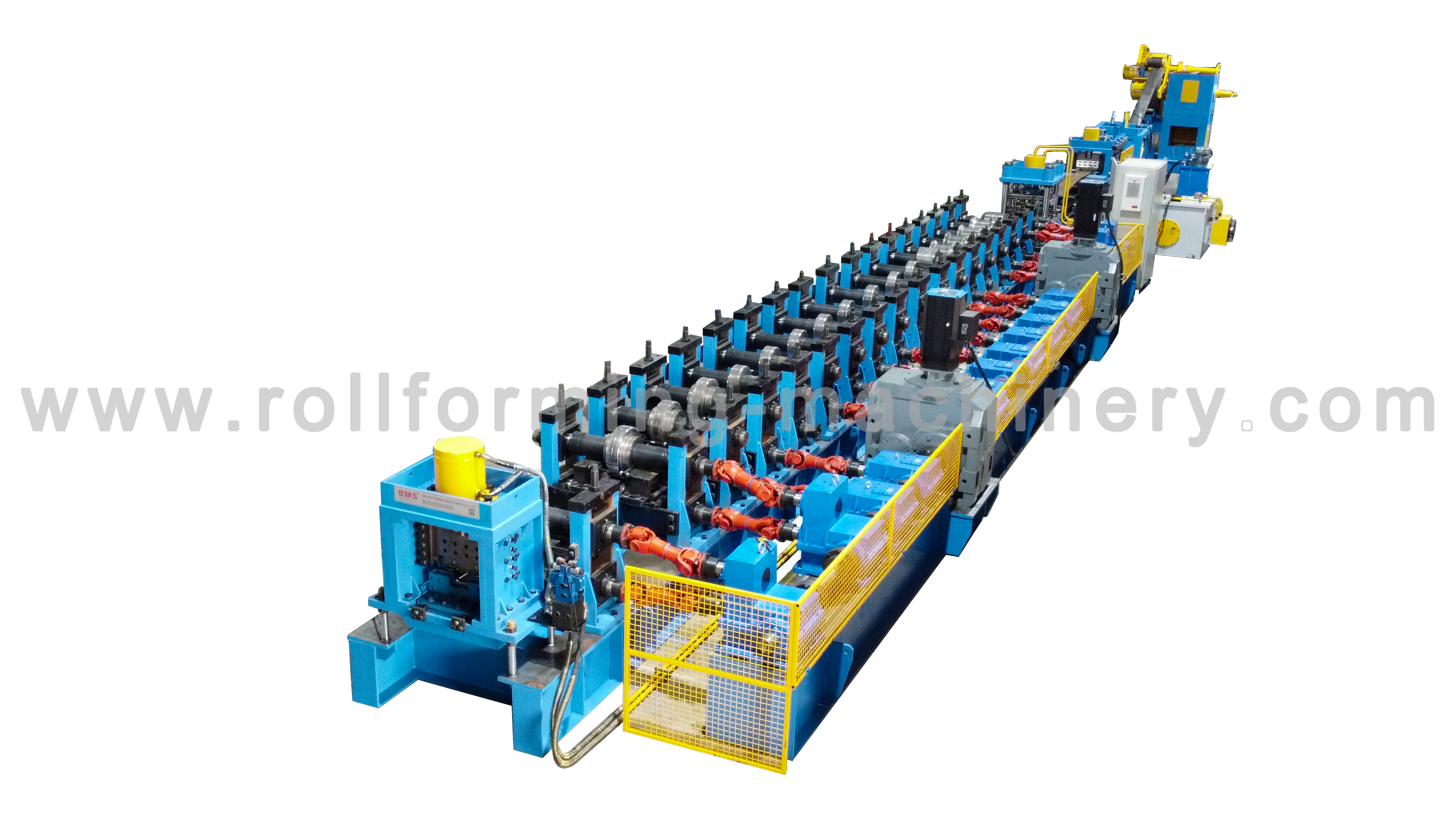

A cold roll forming machine produces continuous, uniform cross-section profiles by progressively shaping metal strips through a series of roller dies at room temperature. This process does not use heat, so the products stay strong and exact. You can trust this machine to make parts with high accuracy and steady quality. The machine bends and shapes metal into the profiles you want for your work. You can make many different shapes and designs with this method. The machine is great for making lots of pieces because it works by itself and gives the same results every time.

Tip: You can use a cold roll forming machine with steel, aluminum, brass, or copper. This lets you make many kinds of products for different needs.

Key Features

The roll forming machine is special because of its features. You can see the main points in the table below:

Feature | Description |

Thickness Capability | Bends sheets up to 3 mm from steel, aluminum, brass, or copper. |

Profile Complexity | Makes complex and exact profiles with rollers. |

Production Process | Works all the time and can change speed for more output. |

Precision Control | Uses computers for automatic and exact forming. |

Space Efficiency | Fits well in most factory spaces. |

Cost Efficiency | Needs less tooling and costs less than other ways. |

You save money because the roll forming machine uses less tooling and makes less waste. The rollers are made to be very exact, so you get tight fits and perfect shapes. You also get flexibility, since the machine can make many profiles and work with different thicknesses. The cold forming process makes your products strong but light and helps with green manufacturing.

Typical Applications

Roll forming machines are used in many industries. These machines help you make lots of products for different jobs. Here are some common uses:

Construction: You can make wall studs, roof panels, and steel frames.

Automotive: You can make body panels, chassis parts, and strong supports.

Appliance Manufacturing: You can make frames, panels, and brackets for home appliances.

HVAC Systems: You can make air ducts, frames, and covers.

You can use the roll forming machine to make profiles for shelves, racks, doors, and more. The machine can make many pieces fast, so you can finish big projects. You will see cold roll forming used when you need metal parts that are strong, exact, and always the same.

Working Principle of Roll Forming Machine

Continuous Bending at Room Temperature

You use a roll forming machine to shape metal strips by bending them step by step. The machine works at room temperature, so you do not need to heat the metal. You feed a long strip of metal into the roll forming machine. The rollers bend the metal a little at each station. This method keeps the metal strong and gives you a smooth finish. You can make many shapes without changing the temperature. The roll forming process helps you save energy and keep your workspace safe.

Note: Cold roll forming gives you strong parts because the metal gets harder as you bend it at room temperature.

Material Flow and Deformation

When you start the roll forming process, the metal moves smoothly through the machine. The feeding guide lines up the strip so it enters the first set of rollers straight. Each roll forming station bends the metal a bit more. You do not see cracks or breaks because the machine bends the metal slowly and evenly. The roll forming machine can handle many types of metal, like steel or aluminum. You can add punching or notching before or during the bending steps if you need holes or special features.

Here is how the material flows through the roll forming machine:

You load the metal coil onto the decoiler.

The feeding guide moves the strip into the first rollers.

The leveling device flattens the strip.

The roll forming stations bend the metal into the shape you want.

The hydraulic cutter cuts the finished profile to the right length.

The exit rack collects the final product.

You get better dimensional accuracy because the machine controls each step. The roll forming process lets you make complex shapes with less waste.

Precision and Tolerances

You can trust a roll forming machine to give you high accuracy and a good surface finish. The roll forming process creates tight tolerances, so your parts fit together well. You can add special tooling to make almost any shape you need. The machine uses a PLC control system to set the length, batch, and punching details. You just enter your numbers on the touch screen, and the roll forming machine does the rest.

Tip: Cold work at room temperature gives you better dimensional accuracy and a strong, smooth finish.

When you compare roll forming to other methods, you see some differences:

Roll forming can make complex shapes, but cold drawing gives even tighter tolerances.

Sheet metal cutting and folding work best for simple shapes and give moderate precision.

Cold roll forming gives you very good tolerances and lets you add features during the process.

You get consistent results with every batch. The roll forming machine helps you keep your production line fast and your parts exact.

Cold Roll Forming Machine Components

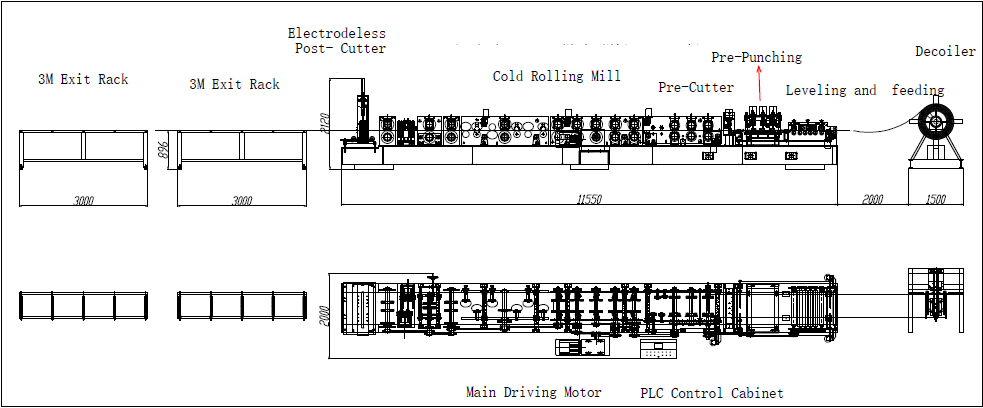

Decoiler and Feeding Guide

You start the roll forming process by placing a metal coil onto the decoiler. The decoiler holds the coil steady and feeds the strip into the roll forming machine. This step is important because it keeps the metal straight and prevents stress or misalignment. When you use a decoiler, you avoid jams and keep your workflow smooth. The feeding guide lines up the metal strip before it enters the rollers. This guide makes sure the strip stays centered, which helps you avoid defects in your finished products. If you want to make high-quality products every time, you need to pay attention to this first step.

Tip: A well-adjusted decoiler and feeding guide help you reduce waste and improve the accuracy of your roll forming machine.

Leveling and Pre-Punching

After the metal leaves the decoiler, it passes through the leveling device. The leveler flattens the strip and removes any bends or curves. You get a smooth, even strip that is ready for shaping. If your products need holes or slots, you use the pre-punching unit next. This unit punches holes or notches in the metal before it reaches the rollers. You can set the punching pattern using the control system. This step saves you time and lets you add features to your products without extra work later.

Here is a quick look at what these components do:

Component | Function |

Leveler | Flattens the metal strip for smooth feeding. |

Pre-Punching Unit | Adds holes or notches before forming. |

You get more flexibility and can make many types of products with these features.

Roll Forming Stations

The roll forming stations are the heart of your roll forming machine. You feed the leveled and punched strip into a series of roller stations. Each station bends the metal a little more, step by step. The rollers shape the strip into the final profile you want. The number of stations depends on how complex your product is. Simple shapes may need only a few stations. If you want to make complex profiles with many bends, you may need 15 or more stations.

You can see how the roll forming stations work in this process:

The strip enters the first station and gets its first bend.

Each new station adds another bend or shape.

The last station finishes the profile, making sure it matches your design.

The rollers in each station are custom-made for your products. You get precise shapes and smooth surfaces. The drive system moves the rollers in sync, so you get even bends and no twists. You can make many products quickly and with high accuracy.

Note: The number of roll forming stations depends on part geometry, material type, part length, and production volume. You can adjust your machine to fit your needs.

A roll forming machine gives you control and flexibility. You can make simple or complex products, and you can change the setup for new designs. The roll forming machine helps you keep your production line running smoothly and your products consistent.

Hydraulic Cutter

You use the hydraulic cutter to finish each metal profile. This part uses hydraulic power to cut metal to the length you want. The cutter works fast and gives you smooth, clean edges. You do not have to stop the machine for every cut. The hydraulic system moves the blade with strong, steady force. This helps your production line keep moving at the same speed.

The hydraulic cutter works with the rest of the machine. When the profile is the right length, the cutter slices through the metal in one move. You get the same result every time you use it. The machine can cut different materials and thicknesses without slowing down or losing accuracy.

Here is a simple table about what the hydraulic cutter does and how fast it works:

Function of Hydraulic Cutter | Typical Cutting Speeds |

Cuts metal profiles to the right length using hydraulic power for accuracy and speed | About 20 to 25 meters per minute, depending on the machine and material |

You can change the settings to fit your needs. The hydraulic cutter helps you save time and make less waste. You get more finished pieces faster, so your work is more efficient.

Tip: Always check the hydraulic system for enough oil and smooth movement. This helps your machine work its best.

Cold Roll Forming Process Steps

Setup and Preparation

You get ready by cleaning your workspace and tools. A neat area helps stop accidents and keeps the roll forming machine working well. You check if the floor is flat and strong. This stops shaking and keeps things lined up right. You look at the electrical and hydraulic systems to make sure they work. You gather all your tools before you start. Doing these things helps you stay safe and work better.

Tip: Always keep your workspace clean and clear. This helps you stay safe and makes your machine work well.

Here is a checklist for setup and preparation:

Clean your workspace and take away anything in the way.

Make sure the floor is flat and strong.

Check the electrical and hydraulic systems.

Get all the tools and equipment you need.

Material Loading and Feeding

You put the metal coil on the uncoiler. Use lifting tools so you do not get hurt and the coil stays safe. Never do this step alone. Read the manual and finish training to know the safety rules. Wear safety clothes to protect yourself.

Guide the strip from the uncoiler to the feed table. The feed table holds the strip and stops it from snapping back. The entry guide makes the sheet straight. Feed rolls control how fast and tight the strip moves. Keep all guards and covers on when the machine is running. Follow all safety rules when you load or unload coils.

Part | Function | Types | Factors |

Uncoiler | Holds coil stock, lets it unwind | Decoiler, Hydraulic mandrel, Reel | Coil width, I.D. & O.D |

Feed Table | Holds strip end, stops recoil | Flat/Inclined with rollers | Recoil force |

Entry Guide | Makes incoming sheet straight | Pyramid, Roller straightener | Material thickness |

Feed Rolls | Controls speed and tension | Knurled, Smooth friction | High friction for thin sheets |

Note: Always use the roll forming machine with another person for safety.

Progressive Forming

You start the main job by feeding the metal strip into the roll forming stations. The strip goes through each station, and the rollers bend it a little at a time. You do not stop the machine between steps. Each station shapes the strip more until you get the profile you want. Lubrication helps stop rubbing and keeps the surface nice. The straightening stage fixes small mistakes. The roll forming machine keeps the speed and pressure the same, so every piece looks the same.

The table below shows the main steps in the progressive forming process:

Stage | Description |

Uncoiling and feeding | The coil unwinds smoothly so it does not tangle. |

Guiding and entry | The strip goes into the rolls straight and centered. |

Flattening | The coil gets flat for the roll forming process. |

Progressive forming | Rollers slowly bend the strip to the final shape. |

Lubrication | Stops rubbing and keeps the surface safe. |

Straightening | Fixes small mistakes for straight pieces. |

You use the PLC control system to set the length, batch size, and punching details. You type your numbers on the touch screen. The roll forming machine then works by itself and makes the same profiles every time. You watch the process to make sure everything is going right.

Tip: Check the lubrication and alignment often during production. This helps your roll forming machine work its best.

Cutting and Stacking

Cutting and stacking are the last steps in cold roll forming. These steps change a long metal strip into finished profiles. Machines and controls help keep everything fast and correct.

When the profile is long enough, the hydraulic cutter starts. The PLC control system checks the length and tells the cutter when to cut. The machine does not stop for each cut. The cutter goes through the metal fast and leaves smooth edges. This way, every piece is the same size and looks neat.

After cutting, the profiles go to the exit rack. The exit rack holds each piece as it comes out. You can stack the profiles by hand or use an automatic stacker. Automatic stackers save time and make work easier. They help keep your area neat and get products ready for packing or the next job.

Here is a table that shows where cutting and stacking fit in the roll forming process:

Step | Description |

Uncoiling | The raw material is uncoiled for processing. |

Feeding and Guiding | The material is fed and guided into the roll forming machine. |

Roll Forming | The material is shaped into the desired profile through a series of rollers. |

Cutting Off | Shear cutting is employed to achieve precise lengths for the formed product. |

Collection | The finished products are collected for stacking and further processing. |

Tip: You can change the cutting length and batch size on the PLC touch screen. This lets you make different sizes fast and keeps your work flexible.

You should check the cutter and stacker often to make sure they work well. Checking helps stop jams and keeps your line moving fast. Using machines for cutting and stacking makes your work quicker and your products better.

Advantages of Cold Roll Forming

High Efficiency and Speed

Cold roll forming works fast and saves time. You put long metal strips into the machine. The machine shapes the metal without stopping. This helps you make many pieces quickly. You do not need to pause between steps. Modern machines can go from 10 to 100 meters each minute. Some machines for roof panels run at 30 to 60 feet per minute. You can make up to 12,000 pounds every hour. These numbers show cold roll forming is great for making lots of products.

You do not need extra handling or much manual work. The machine works by itself after you set your numbers. You get more good products in less time. This helps you finish big orders and meet deadlines. The process works with many metals and thicknesses. You can make different products without slowing down.

Note: Fast production means you can send out many good products quickly. This helps your business stay ahead.

Consistent Quality

Cold roll forming gives you the same quality every time. The machine uses rollers and computers to keep each piece exact. You get the same shape, thickness, and look for every product. This is important when you make many parts. Small mistakes can cause problems later.

Cold roll forming makes smooth and clean surfaces. Your products look nice and work well. You check your products often to find any problems early. This helps you keep your standards high.

Here is a table that shows how cold roll forming keeps quality steady:

Aspect | Description |

Precision | Accurate thickness and dimensional control |

Surface Quality | Superior finish compared to hot rolling |

Mechanical Properties | Enhanced strength and hardness |

Inspection Procedures | Early detection and correction of defects |

Testing | Regular checks to meet specifications |

You can count on cold roll forming for good products in tough jobs like construction and cars.

Material Savings

Cold roll forming helps you use almost all your material. You waste very little metal. Scrap rates are only 1-3%. Other ways like stamping can waste 15% or more. This saves you money and helps the environment.

Cold roll forming wastes just 1-3% of the metal.

Stamping can waste 15% or more.

You save money and resources every time you make something.

You can make parts at any length you need. This means you only use what you need for each job. You can fill custom orders or make lots of pieces. You get more products from each coil. This makes your work cheaper and better for the planet.

Tip: Less scrap means you spend less on metal and trash. This helps you earn more money.

Versatility

You get a big benefit when you use a cold roll forming machine. This machine can change to fit what you need. It helps you make many different products. You do not have to stick to simple shapes or just one metal. The roll forming process lets you design and make profiles for many jobs.

You can make lots of shapes with a cold roll forming machine. The rollers bend metal into C-channels, U-channels, omega profiles, and Z-sections. You can also make special shapes for unique projects. Some shapes are hard or even impossible with other machines. The machine bends metal slowly, so you can make tricky designs without extra tools.

Tip: You can switch to new profiles by changing the roller setup or using the control system. This makes it easy to handle new orders or changes in what people want.

You do not have to use only one kind of metal. The machine works with steel, aluminum, and other alloys. You can pick the best material for your project. This helps you make things for building, cars, furniture, and more. You can make strong steel frames for buildings. You can make light aluminum parts for cars. You can also make custom profiles for shelves and racks.

Here is a table that shows how cold roll forming machines can do many things:

Feature | Benefit for You |

Shape Variety | Make C, U, Z, omega, and custom profiles |

Material Flexibility | Process steel, aluminum, and other alloys |

Industry Applications | Use in construction, automotive, furniture, HVAC |

Design Adaptability | Adjust rollers for new shapes and sizes |

You can make just a few pieces or a lot at once. The machine lets you set the length, batch size, and punching details on the PLC touch screen. You can change settings fast and keep working. This helps you finish orders on time and make custom products.

Note: You can add holes, notches, or embossing while you form the metal. This saves time and means you do not need extra machines.

You do not have to worry about changing metals or shapes. The cold roll forming machine gives you what you need to stay ahead. You can make more products and help more customers. This versatility makes your work faster and helps you earn more money.

You get more choices and better results with a cold roll forming machine. You can make things for many jobs, use different metals, and design hard shapes. This flexibility helps your business grow and keeps your clients happy.

Limitations and Considerations

When you want to use a cold roll forming machine, you have to think about some important things. These include how much money you need at first, how long setup takes, and what materials you can use. Knowing these things helps you make smart choices for your factory.

Initial Investment

Buying a cold roll forming machine costs a lot of money. You have to think about more than just the price of the machine. There are other costs too. The table below shows the main things you will pay for:

Cost Component | Description |

Purchase Price | The price changes a lot; small machines cost about $20,000, but big ones can cost hundreds of thousands of dollars. |

Delivery and Installation Costs | These costs depend on where you are and how big the machine is; big machines need special help and cost more to move and set up. |

Modifications to Production Facility | You might need to fix your building, like adding new wires or better air systems, which adds more cost. |

Training and Support | You need to learn how to use the machine; this can cost extra if you get help from the company or others. |

You need to save enough money for all these things. The total cost can be high, especially if you want a big or fancy machine. If you plan ahead, you will not be surprised by the costs and your project will go well.

Design and Setup Time

You also need to think about how long it takes to get your cold roll forming machine ready. Each machine needs special changes to fit your product’s shape and size. You work with engineers to design the right rollers and set the machine. This can take weeks or even months if your product is hard to make.

You have to test the machine before you start making lots of pieces. Testing helps you find and fix problems early. You might need to change your tools or machine settings. This setup time is important because it helps your machine work well and your products turn out right.

Note: If you plan carefully during setup, you save time and money later. You get better results if you do not hurry.

Material Constraints

Not every metal works the same in a cold roll forming machine. Some metals are harder to use. You should remember these things:

High-strength steel needs more force and smaller bends, so it is harder to shape.

You might see more stress and uneven shapes with high-strength steel, which can make your finished product less good.

How you set your rollers and bending angles changes your product design and what tools you need.

You must pick your materials carefully. The right choice helps you avoid problems and keeps your machine working well. Always test new metals before making a big batch.

Tip: Talk to your supplier to learn which metals are best for your cold roll forming machine. This helps you get strong and good products every time.

You have learned how a cold roll forming machine works. It bends metal strips into exact shapes. This process is fast and saves material. You get the same quality every time. You can use this machine for many jobs. Before you buy one, think about what you need. Talk to people who know about these machines. Planning ahead helps you use your equipment well.

FAQ

What materials can you use in a cold roll forming machine?

You can use steel, aluminum, copper, or brass. Most machines work with different thicknesses and strengths. Always check your machine’s guide before using a new material.

How do you change the profile shape on the machine?

You change the roller sets to get a new shape. Some machines have modular rollers for quick changes. Always follow the instructions to stay safe.

How accurate are the finished profiles?

The finished profiles are very accurate, usually within ±0.5 mm. The PLC system and rollers help you get the same results every time.

Can you add holes or notches during roll forming?

Yes, you can add holes, slots, or notches. Pre-punching units do this before the metal goes into the rollers. This saves time and cuts out extra steps.

How much maintenance does a cold roll forming machine need?

You should check the oil, clean the rollers, and look at the hydraulic system often. Regular care keeps your machine working well and stops problems.

Is operator training required?

Yes. You need training to use the PLC system, load metal, and do maintenance. Training keeps you safe and helps you get good results.

What safety measures should you follow?

You must wear safety gear, keep guards on, and use lockout steps. Always work with someone else when loading coils or doing maintenance.

How fast can you produce profiles?

The speed depends on your machine and the metal you use. Most machines run from 10 to 100 meters each minute. You can change the speed for different jobs.