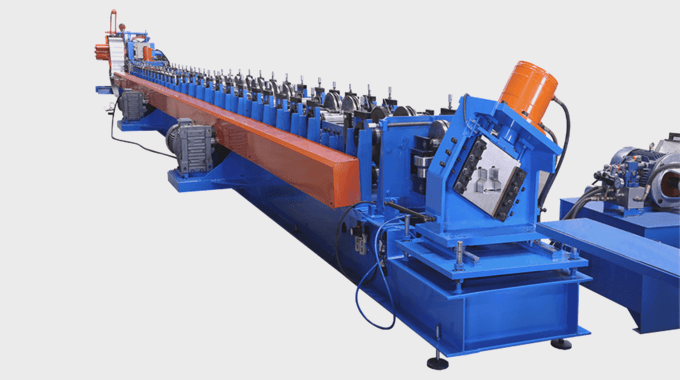

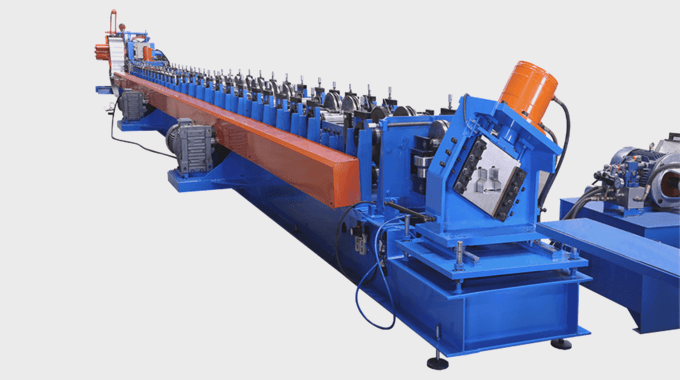

You can see that a cold roll forming machine has many main parts. These include the uncoiler, feeding guide, roll stands, rollers, transmission system, cut-off mechanism, control system, and straightening unit. Each part helps shape materials and keeps the machine working well. If you know about these parts, you can make things more accurate and waste less material. For example, some factories use adaptive control and IoT solutions. These help them make more products and plan better. Here is a simple list of the main parts:

Uncoiler(Decoiler)

Feeding guide

Roll stands and rollers

Transmission system

Cut-off mechanism

Control system

Straightening unit

Key Takeaways

Learn about the main parts of a cold roll forming machine. This helps you make products more accurate and waste less material.

Check the uncoiler's tension settings often. This keeps the machine running smoothly and stops jams from happening.

Use a feeding guide system to keep the metal strip straight. This helps make better quality products.

Pick the right rollers and tooling for your machine. This gives you the same shapes every time and helps the machine last longer.

Take care of the transmission system by checking gears and chains. This helps stop the machine from breaking down without warning.

Use a cut-off mechanism to get the right product lengths. This helps you use less material and waste less.

Use a control system with sensors to watch speed and alignment. This makes sure your products are high quality.

You can add extra modules like punching or welding. These can make your machine work better and do more jobs.

Main Components of a Cold Roll Forming Machine

Uncoiler (Decoiler)

The uncoiler is where the process begins. It holds the metal coil and feeds it into the machine. The uncoiler keeps the coil safe and lets out the strip slowly and evenly. This helps the machine work smoothly and stops it from stopping. Good uncoilers lower the chance of jams or damage to the metal. In factories, the uncoiler is important for moving metal and setting the speed for the whole line.

Tip: Always check your uncoiler’s tension settings. The right tension keeps the strip even and helps make good profiles.

Feeding Guide System

Next, The feeding guide system aligns, centers, and stabilizes the metal strip, ensuring precise and consistent feeding into the roll stands while maintaining tension control to prevent deformation. The feeding guide stops the strip from moving off track. This protects the rollers and helps make accurate shapes. The feeding guide works with the entry guide and leveler to get the metal ready. You find this part in many industries that need exact metal shapes, like building and car making.

Roll Stands and Rollers

Roll stands and rollers are the main parts of the machine. There are many stands, and each one has rollers. The rollers bend and shape the metal strip into different shapes. The main motor runs the transmission system, which moves the rollers together. You can pick special roller tools to make the shapes you want. In factories, roll stands and rollers help make the same metal shapes quickly. These parts help you make accurate and repeatable products, which is important for many jobs.

Component | Function |

Uncoiler | Holds the metal coil and feeds it into the machine. |

Feeding Guide | Moves and lines up the metal strip for the machine. |

Roll Stands/Rollers | Bend the strip into the right shapes step by step. |

Each part works with the others to make good metal shapes. If you take care of your machine and use the right motor and rollers, you can work faster and make better products.

Transmission System

The transmission system, typically equipped with servo drives and synchronization controls, transmits power from the motor to the rollers via gears, chains, or belts, ensuring uniform speed and precise coordination across roll stands. These parts work together to keep the rollers moving at the right speed. The transmission system helps you shape materials the same way every time. If you set it up right, you can work faster and stop less often.

You see the transmission system in many machines in factories. It links the motor to the roll stands so all rollers move together. This teamwork lets you make different shapes from many materials. The transmission system helps you make things fast and meet high standards.

Note: Check your gears and chains often. This helps stop surprise breakdowns and keeps your machine working well.

Cut-off Mechanism

The cut-off mechanism lets you choose how long each product will be. It uses sharp blades to make clean and exact cuts. Automated feeding systems put the material in the right spot before cutting. This makes sure every piece is the same size. New control systems help you cut with less waste and more accuracy.

The feeding mechanism puts the metal strip in the right place.

The shearing mechanism uses sharp blades to cut straight across.

The control system runs the cutting, making it more exact and faster.

You need the cut-off mechanism to get the same results every time, even with tricky shapes. This part is very important for making good products in the roll forming machine.

Control System

The control system runs all parts of the cold roll forming machine. You use it to set the speed, move the rollers, and check if things line up. The control system has sensors to check speed, position, and thickness. These sensors send information to the controller, usually a PLC. The controller tells other parts what to do.

The control system makes work easier by using sensors and actuators.

It keeps the machine steady and correct while shaping metal.

You can set the control system to change roller shapes and positions for different jobs.

This part helps you keep your products good and change fast when you need to. The control system makes sure all parts of your machine work together. It helps you make many shapes from different materials.

Component | Function |

Transmission | Sends power from the motor to the rollers so they move together. |

Cut-off Mechanism | Cuts materials to the right length with sharp blades. |

Control System | Runs and controls the machine for better work and accuracy. |

Straightening Unit

The straightening unit helps make your profiles flat and smooth. It sits after the roll forming section and before the cut-off mechanism. This part uses special rollers to fix any shape problems from forming. When you work with steel or aluminum, you might see coil set or wavy shapes. The straightening unit removes these problems, so your profiles are flat and correct.

Coil straighteners fix coil set and waviness, making the strip flat before cutting.

Multi-roll straightening machines make thin plates smoother by removing big waves.

Tension levelers stretch the metal in two ways, making it flatter with less force.

You get better results when you use a straightening unit. This is important if you need good sheet metal for building or cars. The straightening unit helps you follow strict rules and keeps your work fast. When you use it with other parts, you always make profiles that customers want.

Optional Modules

You can add optional modules to your roll forming machine. These modules help your machine do more jobs and work better. They let you change your machine for different needs and rules. Many factories add new features to make tricky shapes or use more automation.

Intelligent unwinding and leveling systems load, center, and level materials by themselves.

Online punching and embossing modules make holes or add textures while forming.

High-precision roll forming lets you make hard shapes with many steps.

Online welding options, like high-frequency, TIG, or laser welding, make closed profiles right on the line.

Intelligent cutting and sorting modules use flying saws or lasers and robots to cut and stack pieces.

Quality inspection terminals use lasers and AI to check size and surface problems right away.

When you pick the right modules, your machine can do more things. You can work with more materials and shapes, which helps you stay ahead in the factory business. These modules also mean less hand work, better products, and smoother running machines. If you buy advanced modules, you get faster work and better results every time you make something.

Uncoiler and Feeding Guide

Uncoiler Function

The roll forming process starts with the uncoiler. This part holds the metal coil and lets it out slowly. The uncoiler keeps the tension the same, so parts stay good. If you set up the uncoiler right, you stop problems like bent or uneven pieces. The uncoiler also lines up the coil, so the strip goes into the next part easily. If the uncoiler does not work, you might get more waste and have to stop the line. In factories, the uncoiler gets materials ready for shaping. It is a very important part of the machine.

The uncoiler keeps tension steady to protect part quality.

Good coil alignment from the uncoiler stops forming problems.

If the uncoiler fails, you get bent parts and more waste.

Feeding Guide Role

After the uncoiler, the feeding guide moves the metal strip into the roll forming machine. This guide keeps the strip straight and in the right spot. This is important for making things the right size. The feeding guide stops the strip from moving or twisting. In factories, feeding guides work with electronic roll feed systems. These systems help keep speed and position the same. You see feeding guides in many places where you need things to be exact.

Feeding guides make sure the strip goes into the rollers straight.

Advanced feed systems keep speed and position even.

A good feeding guide helps you work faster and make fewer mistakes.

Impact on Material Quality

You can see how the uncoiler and feeding guide help material quality right away. When you use both parts right, you waste less and work better. The uncoiler keeps the coil tight and lined up, so you start with good materials. The feeding guide keeps the strip in place, so you do not get bent or twisted pieces. You get less waste and better results in your work.

Component | Impact on Quality | Role in Efficiency |

Uncoiler | Keeps coil tight and lined up | Gets materials ready |

Feeding Guide | Keeps strip straight and correct | Lowers waste and mistakes |

Tip: Check your uncoiler and feeding guide often for damage or if they are not lined up. This helps keep your materials safe and your machine working well.

You use these parts to keep your work good in the factory. When you care about quality and working fast, you make better products and keep your line running.

The feeding guide keeps the strip in the right spot and at the right speed, so you waste less.

Tight controls help you make things the right size.

You get fewer problems with bent or twisted pieces, so you waste less.

Roll Forming Unit and Transmission

Roll Stands Structure

Roll stands are like the backbone of the roll forming unit. These parts hold the roller dies that shape metal profiles. The forming section uses stands with roller dies. Each stand keeps the rollers in the right spot. Engineers use special computer programs to design the roller die shapes for each profile. Machines make the tooling with exact shapes, so there is less friction and wear. A strong machine base keeps the rolls and tooling lined up. If the base shakes or moves, the rolls can get out of place or vibrate. This can make your finished profiles less accurate and lower their quality. That is why factories build strong bases to help the machine work better and last longer.

Stands hold roller dies for shaping.

Computer programs help design roller shapes.

Exact machining means less friction and wear.

Strong bases keep rolls lined up and profiles correct.

Rollers and Tooling

Rollers and tooling are very important for shaping materials. Rollers are made from different materials, and each type has its own good points for making things. The table below shows some common types and what they do:

Material Type | Benefits | Limitations |

Nylon | Quieter, less friction, does not rust easily | Cannot hold heavy loads, does not like heat |

Steel | Can hold heavy loads, works in high heat, lasts long | Makes more noise, needs oil often |

Good rollers last a long time and make smooth surfaces. Rollers that do not rust are needed for fast and careful work in factories. Chrome coating on rollers protects them from tough places and keeps pressure even. This helps you make the same products every time and stops the rollers from wearing out fast. Picking the right rollers and tooling helps you work faster and make better products.

Shafts and Transmission System

Shafts link the rollers and send power from the transmission system. You need these parts to keep the forming process working together. How the shafts and transmission system are made changes how well the machine works. If the motion between threaded parts does not match, you can get mistakes in the splined part. If the space between the workpiece and rolling die changes, the speeds might not match, and this can cause errors in the profiles. The shape of the billet changes the outside sizes and affects how exact the rolled parts are.

Evidence Description | Impact on Synchronization |

Threaded section movement | If not matched, can cause mistakes in splined part |

Center distance changes | Different speeds can make profile errors |

Billet shape | Changes how exact the rolled parts are |

You need good shafts and transmission systems to keep all parts moving together. This helps you work faster and make profiles that are the right size. In factories, strong transmission systems are needed for good results and machines that last a long time.

Ensuring Profile Quality

You want every profile to be good and meet high standards. Good quality means each piece looks right and fits where it should. To do this, you must check the main parts and set up your machine well.

First, look at your roll stands and rollers. Make sure they are lined up and not loose or worn out. If you see worn or loose parts, fix them fast. This helps keep your profiles the same shape. Use the right rollers for your materials. Some materials need harder rollers, others need smoother ones. For example, steel needs strong rollers. Softer metals like aluminum need smooth rollers.

Tip: Clean your rollers before you start a new job. Dirt or old metal can scratch your profiles and make them worse.

You also need to check the transmission system. If gears or chains slip, rollers may not move together. This can bend or twist your profiles. Check shafts to see if they are straight. Make sure all parts move without problems. A good transmission system helps your machine work well.

Here is a simple checklist to help you keep quality high:

Check all parts before each shift.

Use the right rollers for your material.

Make sure rollers are lined up and set right.

Keep the transmission system clean and oiled.

Listen for strange sounds or shaking when running.

Step | What to Check | Why It Matters |

Roller Alignment | Rollers line up with strip | Stops uneven shapes |

Transmission System | Gears and chains move well | Keeps speed and works better |

Material Choice | Right rollers for materials | Stops surface damage |

Cleanliness | No dirt on equipment | Stops scratches and problems |

In factories, you must also check your results. Measure the width, height, and thickness of finished profiles. Use calipers or laser tools for best results. If you see changes, fix your machine right away. Many factories use sensors and control systems to watch quality all the time. This helps you fix problems fast and keep things working well.

You help keep your machine in good shape. When you follow these steps, you help your company do better and make great products. Good profile quality means less waste, better fit, and a strong name in the business.

Cut-off Mechanism and Straightening

Cut-off Press Types

The cut-off press cuts finished profiles from the strip. Every roll forming line needs this part. There are different types of cut-off presses for different jobs. The most common types are flying shears, hydraulic presses, and rotary cutters. Flying shears move with the strip and cut while it moves. Hydraulic presses use strong force to cut thick materials. Rotary cutters spin fast and slice thin profiles quickly. This helps you make more products in less time.

Cut-off Press Type | Best Use Case | Speed | Precision |

Flying Shear | Continuous production | High | Good |

Hydraulic Press | Thick materials | Medium | Excellent |

Rotary Cutter | Thin, fast profiles | Very High | Good |

You pick the right cut-off press for your machine and materials. Using the best press helps you keep your work fast and good.

Tip: Check your cut-off press blades often. Sharp blades make clean cuts and help you waste less.

Straightening Unit Function

After cutting, the straightening unit fixes any bends or twists. This part uses force to make the profiles flat and straight. There are three main ways to straighten profiles:

Global straightening fixes big bends or twists in the whole profile.

Local straightening fixes small spots, like where pieces join.

Progressive straightening makes small fixes along long profiles.

Smart straightening systems use sensors and change how they work as needed. These systems stretch, bend, and press the metal. Sometimes, they do this more than once to fix spring back. This helps you get flat and even profiles every time.

Note: Straightening units help you follow strict rules for flatness and shape, especially with steel or aluminum.

Quality Control After Forming

Quality control is very important after forming and straightening. You check each profile for size, flatness, and smoothness. Many factories use lasers and sensors to check every piece. You look for problems like warping, rough edges, or marks. If you find a problem, you fix the machine or tools.

You write down your checks to see patterns and work better. Good quality control helps you make products people trust and keeps your company’s good name. It also helps you waste less and save money by finding problems early.

Always watch your straightening unit and cut-off press. Fixing problems fast keeps your line running well.

Control System in Roll Forming Machines

Operation Management

The control system helps run every part of the roll forming process. It links all the main parts and keeps things working well. You set things like where stands go, how fast to feed, and when to cut. The control system uses PLC to move stands and change feed speed by itself. You get help from punching and moving materials without much hand work. New roll forming machines do many jobs at once, like punching, notching, and embossing. This makes the line faster and uses less material.

Operation Parameter | Description |

Stand Positions | PLC controls stand spots for good forming. |

Feed Rates | Changes by itself for best speed and flow. |

Cutoff Timing | PLC sets when to cut for right lengths. |

Integrated Punching | Does more than one job at once to save time. |

Tip: Check your control system before each shift. This keeps your machine working its best.

Speed and Alignment Control

The control system watches speed and keeps things lined up. Sensors check how the material moves and send info to the system. The system changes speed and lines things up right away. This keeps shapes correct and stops waste. The control system helps stop jams and keeps things from getting out of place. This saves your materials and keeps quality high. Speed control lets you use different materials and meet rules for good work. You get the same results every time and work fast.

Note: Listen for strange sounds or look for uneven moves. These can mean something is not lined up right.

Enhancing Process Quality

The control system helps make better products and stops mistakes. It checks each piece for size, shape, and smoothness. You find problems early and do not have to fix things later. The control system helps you follow rules and keeps your business safe. The system finds slow spots and helps you work better. You get good materials from suppliers because you check them first. Customers trust your work because you always give good products.

Better products make customers happy.

You save money when you stop mistakes early.

You work faster by using your tools and time well.

Following rules keeps your business safe.

Always getting better helps you stay ahead.

Good products make customers come back.

Good suppliers help you get better materials.

Check your control system reports often. This helps you see problems and make your line better.

Optional Components and Customization

Punching and Welding Units

You can add extra parts to your cold roll forming machine. These parts help you work faster and make more things. Punching and welding units are very popular upgrades. They let you make special shapes and meet different needs.

Punching units press hard to make holes or notches in metal sheets. You can do this before shaping the metal. This helps you make profiles for many uses.

Welding units use lasers to join seams and joints. This makes your profiles stronger and look better. You can weld as the line moves, which saves time and helps you work faster.

Here is a simple table about these parts:

Component Type | Description |

Welding Unit | Uses lasers to weld seams and joints very well, making the profile stronger. |

Punching Unit | Uses high pressure to make holes or notches in metal sheets, so you can change the profile as needed. |

You can also add other things like notching, logo printing, and embossing. These options help you make products for many jobs, like building or car making. When you use these units, you can work with many materials and make profiles that are special.

Tip: If you add punching or welding units, you can finish more steps at once. This means you touch the metal less and your profiles stay the same.

Integration for Custom Profiles

You can change your roll forming line to make special profiles for customers. Adding extra modules lets you change how your machine works. You can add new fields, set up special steps, or connect other tools. This helps you do what each industry needs.

Customization Aspect | Description |

Fields and Data Architecture | Changes data for each industry, making it more useful. |

Validation Standards and Workflows | Lets you add special steps to fit your work. |

Integration of Third-Party Solutions | Connects outside tools to do more jobs and fit your needs. |

You can set up your line for different materials and shapes. This means you can make profiles for building, trucks, or energy jobs. Changing your line helps you keep up with new trends and what customers want. You can also work faster by using more machines to do the work.

When you pick the right parts and modules, you can make things faster and better. You also waste less and your line can do more jobs. This helps you do well in a busy market and give customers what they need.

Roll Forming Process and Component Interaction

Step-by-Step Process Flow

You can use a simple step-by-step process to turn raw materials into finished profiles. Each step uses special machine parts to keep things moving and make good products. Here is how the process usually goes in factories:

Coil Loading: You put metal coils on the uncoiler with a coil car.

Coil Flattening: The coil goes through a flattener to make it flat.

Lead End Trimming: You cut the lead end and join it to the last coil’s end.

Strip Accumulators and Slack Loops: These hold strip sections so the line does not stop.

Pre-Punch Presses: The strip can go through punch presses to make holes or notches.

The Roll Die Mill: The flat strip moves through roller die stands to get shaped.

Cutoff & Discharge: The shaped metal is cut to the right length and leaves the line.

Secondary Operations: You can add more steps, like extra punching or putting parts together.

This roll forming process helps you make accurate profiles quickly. You can change each step for different materials or products.

Synchronization of Components

All parts must work together for a smooth roll forming process. Synchronization keeps machines at the right speed and makes sure every profile is good. Here is how you can keep everything working together:

Make sure everyone in the supply chain knows their job.

Share information so people can make better choices and act fast.

Get real-time data from your machines to watch the process.

Watch and manage the line to find problems quickly.

Check and improve your process to make things better and faster.

When you synchronize your parts, you have less downtime and your line works well. This teamwork helps you make the same profiles every time and keeps customers happy.

Tip: Use real-time tools to find problems early and keep your roll forming process working well.

Troubleshooting for Quality

You might have quality problems during the roll forming process. Fixing problems fast helps you keep profiles correct and machines working well. Here are some common steps you can try:

Tighten or change any loose switches or limit stops.

Change the tolerance or get a new encoder if it is worn out.

Clean the encoder wheel to get rid of dirt.

Look at forming rolls for wear or if they are not lined up to fix shape problems.

Check tooling and oil if you see jams.

Take out anything blocking the line that slows things down.

Troubleshooting Step | Description |

Checking for worn or damaged parts | Change these to keep your machines working right. |

Adjusting the machine | Move rolls or change settings if shapes are wrong. |

Checking for blockages | Remove anything in the way to keep things running. |

You can keep your roll forming process working well by doing these steps. Regular checks and quick fixes help you stop big problems and keep your line running smoothly.

Maintenance and Quality Assurance

Routine Maintenance Tips

You need to take care of your cold roll forming machine often. Clean the machine after every shift to get rid of dust and metal bits. Put oil on moving parts like rollers and shafts so they do not wear out. Check if all parts are lined up before you start working. Make sure bolts are tight and look at chains or belts for stretching. Change old or broken parts fast to stop bigger problems. Use a checklist to remember what to do each day, week, and month. Doing these things helps stop surprise breakdowns and keeps your factory running well.

Tip: Set alarms to remind you to oil and check your machine. Small jobs help your machine work better.

Detecting Component Wear

You can find worn parts early by listening for new sounds or feeling shakes. Watch for changes in how your products look or feel. Look at rollers for scratches or dents. Check the feeding guide and straightening unit for bends or if they are not straight. Use sensors or check by hand to see if profiles are the right size and shape. If you see rough spots or size changes, look at the transmission system and cut-off mechanism. Change any broken tools or materials right away. In factories, finding problems early saves money and keeps things moving.

Here is a table that shows how regular care helps your machine and products:

Benefit | Explanation |

Increased Machine Lifespan | Oiling and checking parts stops them from wearing out. |

Consistent Product Quality | Stops parts from moving wrong and keeps surfaces smooth. |

Reduced Downtime | Stops surprise breaks that slow down work. |

Lower Repair Costs | Fixing small problems early stops big repairs. |

Higher Efficiency | Makes sure the machine works fast and right. |

Maintaining Product Quality

You keep your products good by checking each step. Measure the width, thickness, and surface of profiles after they are made. Use calipers, lasers, or just look closely to find mistakes. Write down what you find to see if there are patterns and to get better at making things. Teach your team to spot problems with materials or machines. In factories, good quality checks make customers trust you and keep your name strong. When you care for your machine and check often, you make profiles people can count on.

Note: Quality checks are not just at the end. You need to watch every step to keep your work good.

You help your company grow by keeping your machine in great shape. Checking and fixing things often protects your money and helps you work better. When you care about quality, you meet rules and make products that last.

You help your cold roll forming machine work its best. When you know about each part, you make the process better. Paying close attention helps you find problems early. This keeps your products high quality. Use what you learn to fix issues fast and keep your work strong. Try these tips to get better results and reach your goals.

FAQ

What does a cold roll forming machine do?

A cold roll forming machine shapes metal strips into special profiles. It bends the metal without heating it up. This makes strong and exact parts for many jobs.

How often should you maintain your roll forming machine?

You need to check and clean your machine every day. Look at rollers, shafts, and guides once a week. Change any broken parts as soon as you see them. Taking care of your machine helps it work well.

Can you change the profile shape on one machine?

You can use different roller tooling to make new shapes. Change the control system and stands for each profile. This lets you make many kinds of products.

Why is the feeding guide important?

The feeding guide keeps the metal strip straight. This stops mistakes and lowers waste. Good feeding helps you get the same high-quality profiles every time.

What materials can you process with a roll forming machine?

You can use steel, aluminum, and other metals. The machine works with many thicknesses and types. Pick the right rollers and settings for each material.

How does the control system improve product quality?

The control system checks speed, alignment, and cutting. You get updates and changes right away. This helps you keep things accurate and stop mistakes.

What optional modules can you add?

You can add punching, welding, embossing, or inspection units. These parts help you make special profiles and do more steps by machine. You work faster and make more products.

How do you detect worn components?

Listen for strange sounds and look for changes in your products. Check rollers, guides, and transmission parts often. Finding problems early helps you stop breakdowns and keep quality high.