BMS Group is a trusted global manufacturer of high-quality roll forming machines, specializing in purlin machines, delivering high-performance solutions for the construction industry. Our product range includes CZ Purlin Roll Forming Machines with quick-change technology, CU Purlin Machines, M Purlin Machines, and Z Purlin Machines etc, designed to optimize efficiency, precision, and reliability. Built with advanced technology and CE-certified for quality, our machines cater to a wide range of structural and industrial applications.

Exporting to over 100 countries, BMS is the trusted partner for global clients in construction and infrastructure, including leading companies such as ArcelorMittal, China State Construction,Zamil Steel and TATA Bluescope Steel. Our ability to customize machines based on specific requirements ensures that we meet diverse customer demands, offering solutions tailored to exact technical and production needs.

At BMS, we provide not only innovative machinery but also a full-service experience, from design and installation to lifelong technical support. With a focus on quality, reliability, and competitive pricing, BMS Group empowers businesses to achieve operational excellence in the fast-evolving construction landscape.

What Is A Purlin Roll Forming Machine?

A Purlin Roll Forming Machine is a specialized piece of equipment used to create steel purlins in various profiles. Through a process called roll forming, raw metal is passed through a series of rollers that shape it into a continuous profile. These machines allow for high-speed, high-precision production of purlins that are critical for supporting roof and wall structures in both commercial and industrial applications.

Product Center

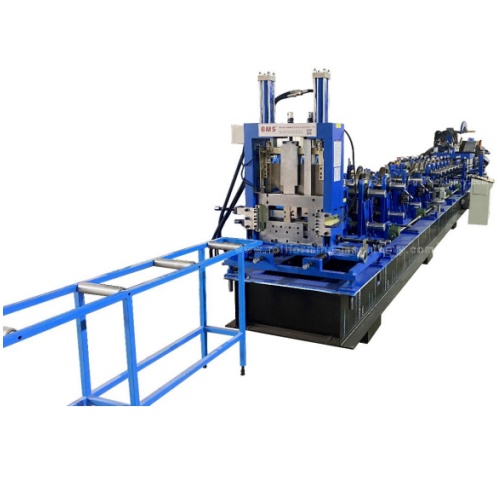

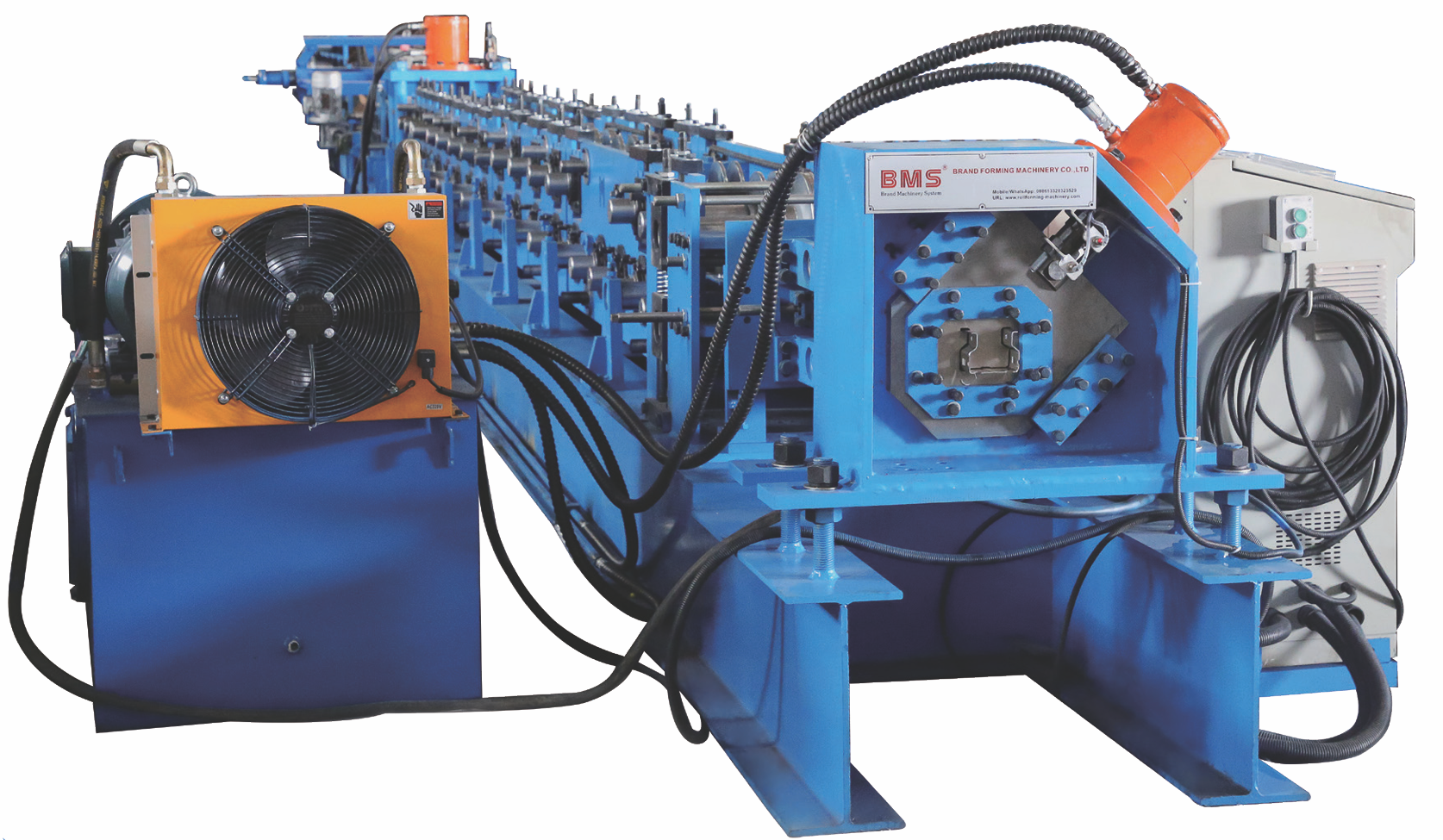

Our premium purlin machines, including CZ Purlin Roll Forming Machines, C Purlin Machines, and Z Purlin Machines etc, designed for precision, efficiency, and versatility. Featuring quick-change technology and CE-certified quality, our machines ensure high-speed production for modern construction needs. Custom solutions are also available to fit your specific needs.

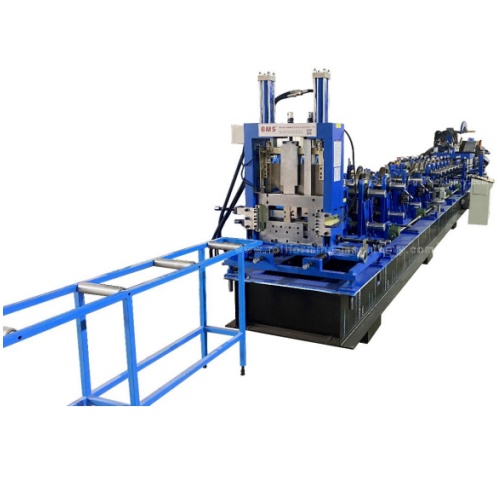

- The advantages of Heavy Duty Design CZ Purlin Machine

1) Produce different purlin size without changing rollers or spacers.

2) No need.changing cutter for different size.

3) Infinite sizing(any size within machine range),help to save material

4) Optional Punch hole at any position of purlin web side and flange

5) Easy operation, low maintenance - A Wide Variety Of Roll Forming Line With World-Class Profile Bending Quality Standards. Need Help Choosing The Right Roll Forming Machine? Contact our experts for free consult. Hight Quality Low Price.

- A Wide Variety Of Roll Forming Line With World-Class Profile Bending Quality Standards. Need Help Choosing The Right Roll Forming Machine? Contact our experts for free consult. Hight Quality Low Price.

- It is mostly used for the supporting role of beams and wall beams in housing construction and factory buildings.

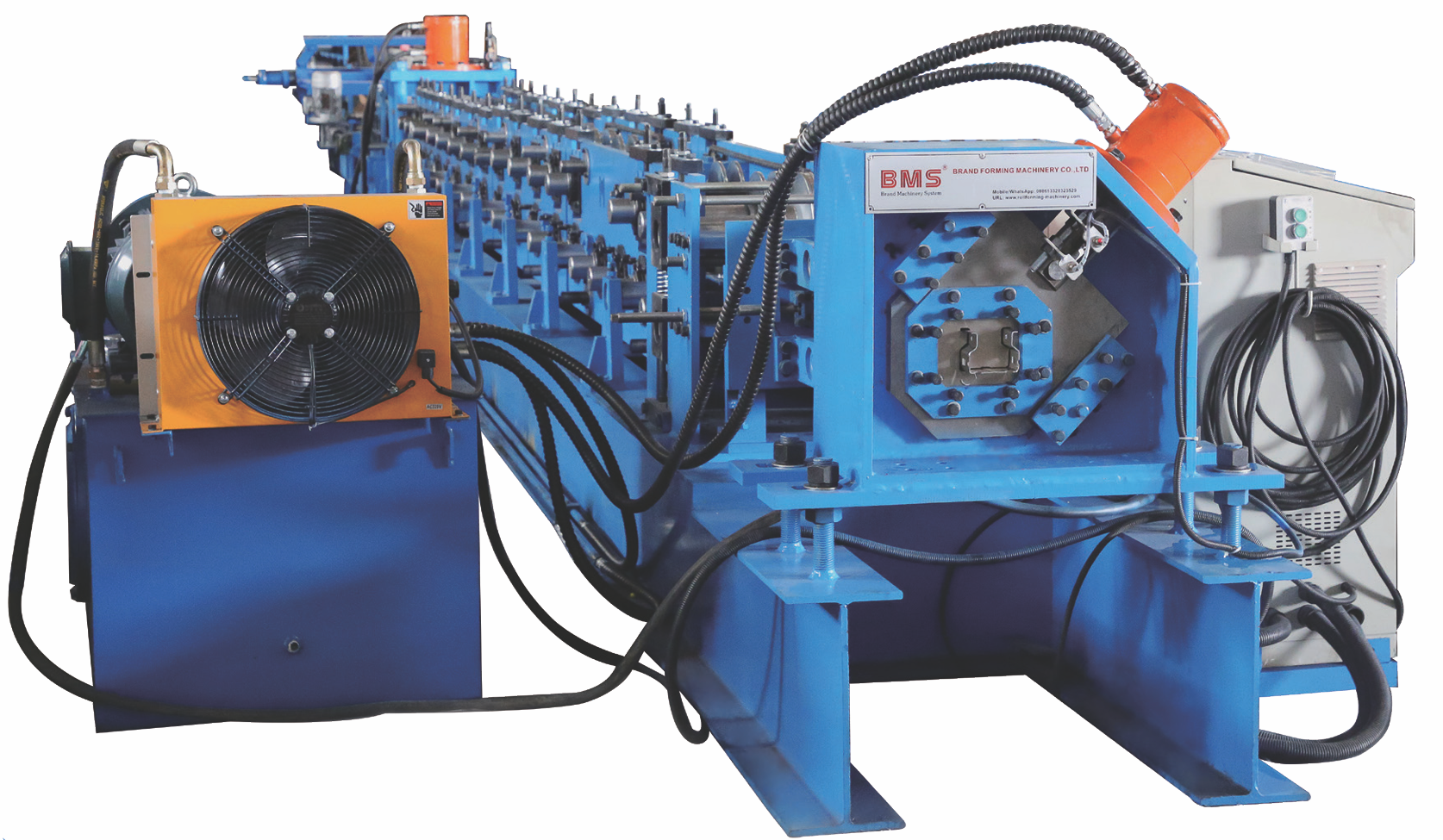

- The C Z Purlin Roll Forming Machine can produce C and Z profiles.

What Are Purlin Machines Used For?

Our Purlin Roll Forming Machines are perfect for producing purlins tailored to these various applications, ensuring reliable performance for every project.

Industrial Buildings

Purlins provide critical support for roofing systems in large industrial facilities.

Commercial Structures

Residential Construction

Factors to Consider When Choosing a Purlin Machine

Selecting the right purlin machine is crucial for achieving efficient and high-quality production. Here are the key factors to consider:

1.Machine Versatility

Ensure the machine supports both C and Z purlin profiles, with quick-change technology for seamless transitions.

2.Precision and Quality

We utilizes cutting-edge Taiwanese technology, and all machines are CE-certified for global safety and quality standards.

3.Customization Options

Choose a machine tailored to your needs. We specialize in bespoke solutions to meet unique technical and project requirements.

4.After-Sales Support

Choose a manufacturer offering lifetime support, installation, and training. BMS, exporting to 100+ countries, delivers reliable purlin machines with excellent after-sales services.

Benefits of Our Purlin Machines

Our advanced purlin machines, including CZ Purlin Roll Forming Machines etc, are designed for precision, efficiency, and durability. With CE-certified quality and quick-change technology, they meet the high-speed production demands of modern construction.

Precision Manufacturing: Deliver accurate and consistent shaping for C,U,M and Z purlins, comply with North American ANSI and AISI standards.

Quick-Change Technology: Allows you to offer clients 24-hour customized C/U/Z section service on various gauges of material, this includes different widths and flange height combinations. Automatic changeover for different C/U/Z sections within 5minutes, saving time and improving work efficiency.

CE-Certified Quality: Globally recognized safety and performance standards.

Customizable Solutions: Designed to meet unique project and material needs.

Trusted Worldwide: Exported to over 100 countries, serving top construction brands.

Affordable Innovation: High-quality machines with competitive pricing for long-term value.

Upgrade your production with our purlin roll forming machines, engineered for reliable and cost-effective performance.

Enhance Your Production with a Floor Deck Roll Forming Machine

Ready to elevate your construction business? Invest in a Floor Deck Roll Forming Machine today and experience the difference in production efficiency, cost savings, and quality. Whether you're focusing on steel decking, residential, or commercial applications, we have the right solution for you. Contact us to learn more about our products and get personalized advice on choosing the best machine for your needs.

Related Blogs

-

Purlin Roll Forming Machines Overview

Purlin Roll Forming Machines OverviewEfficiency and precision are vital in developing construction and manufacturing. The purlin roll forming machine appeared and significantly changed metal fabrication.

-

How to use the CZ purlin roll forming machine?

How to use the CZ purlin roll forming machine?Previously we have described what we should do to prepare before using the CZ purlin roll forming machine and how we should check the CZ purlin roll forming machine. In this article, we will continue what we have done before and talk about how to use the CZ purlin roll forming machine.

-

How does CZ purlin roll-forming machine work?

How does CZ purlin roll-forming machine work?CZ purlin roll-forming machine is a metal manufacturing process that involves bending metal strips to produce a certain shape or design. It is one of the simplest and most understandable metal forming processes. Our company manufactures several types of CZ purlin roll-forming machines, how do these CZ purlin roll-forming machines work? Let's find out in this article!

-

What are the parts of a CZ purlin roll forming machine?

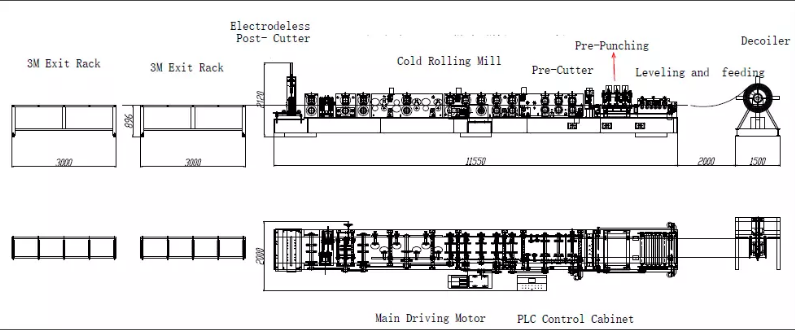

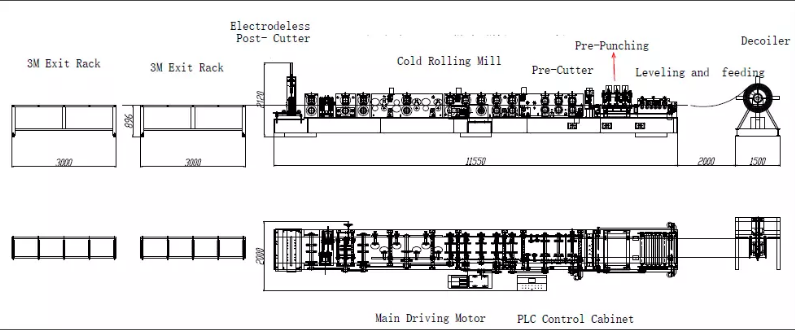

What are the parts of a CZ purlin roll forming machine?The CZ purlin roll forming machine consists of three main parts, including the uncoiler, the forming station, and the section cutting part. It operates roughly in accordance with the following eight parts: manual uncoiler/hydraulic uncoiler → feeding guide → leveling → optional pre-punching and cutting pre-cutting → main roll mill → hydraulic post-cutting knife → PLC control system → discharge stand. This article will give a brief introduction to these parts of the CZ purlin roll forming machine.

-

Preparation steps before use of CZ purlin roll forming machines

Preparation steps before use of CZ purlin roll forming machinesA cold CZ purlin roll forming machine is a machine that continuously bends sheet metal such as coils and strips through a continuous multi-roll forming station to form a metal processing technique for specific cross-sectional profiles. For many novices, using a CZ purlin roll forming machine can be a learning curve. This article will describe the preparatory operations that should be performed before using a CZ purlin roll forming machine.

-

What is a Roll Forming Machine?

What is a Roll Forming Machine?Introduction to Roll Forming MachinesWhat Is a Roll Forming Machine?A roll forming machine is an advanced piece of metal forming equipment used to shape long strips of metal into specific profiles. This process, known as roll forming, involves feeding metal strips through successive sets of rolls th