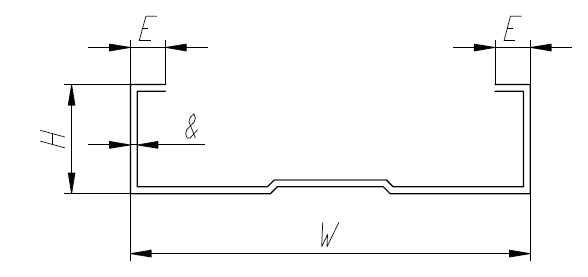

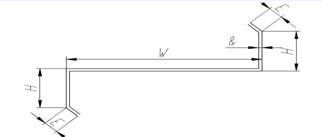

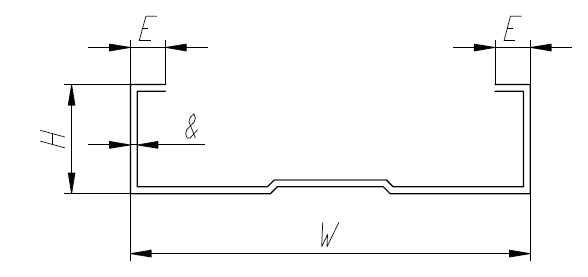

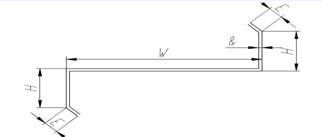

ⅠProfile Drawing

C purlin rib: with or without (optional)

Lip(E) | 10~20±1mm |

Height(H) | C: 40~100±1mm(can’t over 50% of Web) |

| Z: 49~100mm±1mm(can’t over 50% of Web) |

Web(W): | C75~300±1mm |

| Z120~300±1mm |

Length tolerance for 6m:L±3mm

punching hole on both WEB side and Height(Flange) side,tolerance: ±1mm,slot hole size:14x25mm or customized hole for similar size

Punching Holes as follows:

Ⅱ. Material:

Material Thickness: 1.5~3.2mm

Applicable material: 340 Mpa for MS or HR and Galvalume 550Mpa AZ150

Ⅲ. Machine Work Flow

Decoiler → Feeding and Leveling Device → Hydrualic Pre-Cutting&Punching Device→Rolling Forming System→Hydraulic Post Cutting →Product Support Frame

IV. Machine Components

1) Hydraulic Decoiler: one set 5 tons

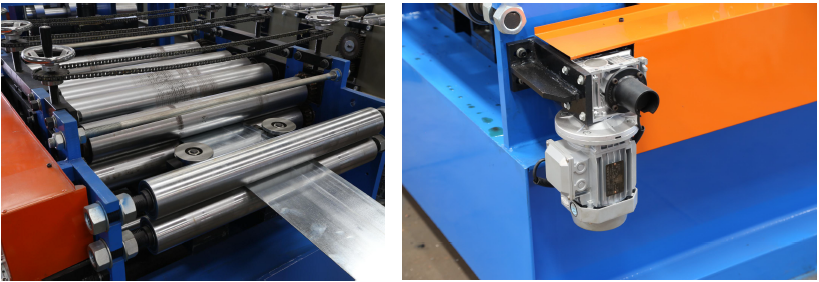

2)Cold Rolling Mill:

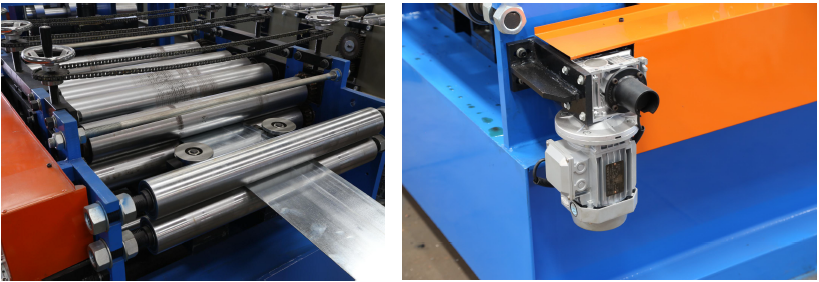

With feeding material guide(Automatic feeding control, save labor cost) and leveling device

Body frame made from national standard 450# H type steel by welding;

Wallboard thickness: 30mm(more thicker, more stronger and stable working for long life)

Rollers manufactured from tooling steel Cr12(D3 steel, for long working life), precision machined,

Shafts manufactured from high quality 45# steel, Main Shafts Diameter=ф90mm,straightening roller shaft diameter=ф100mm,precision machined

Motor Driving, chain sprocket transmission,about 22 forming stations(19-step to form and 3 step for final shaping).

Main Motor=22KW,Frequency speed control

Size changing motor:6pcs, Automatically controlled by PLC Programing.

Forming speed approx.18-20m/min (depending on the number of punching holes)

With squareness roller setup

All the screw bolts with grade 8.8 to ensure fix the machine structure tightly and long life during the machine long time running.

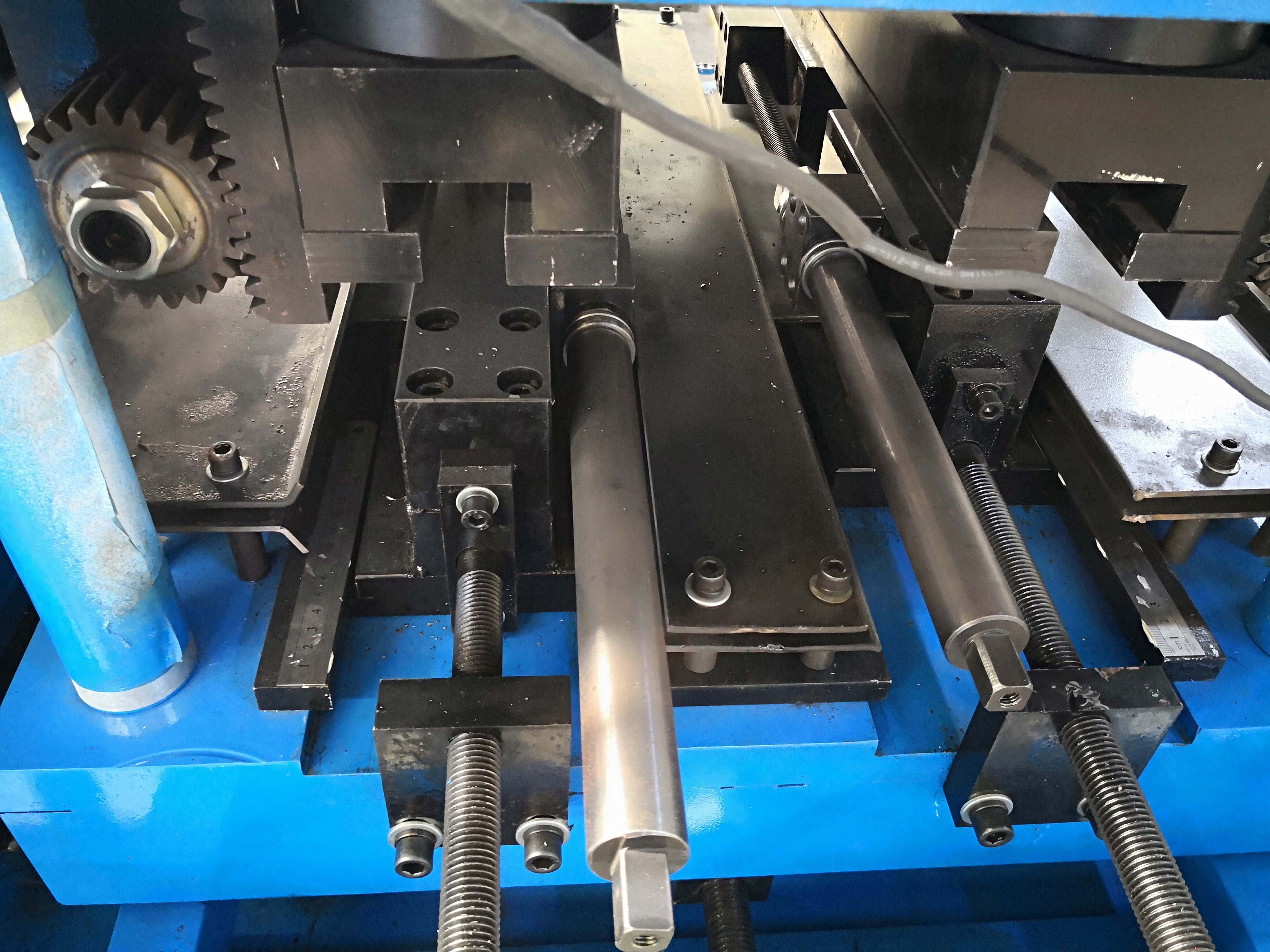

3) Hydraulic Punching and Cutting device:

Pre-punching and pre-cutting, use the same hydraulic system

Hydraulic motor: 7.5kw, Hydraulic pressure range: 16Mpa

Punching and Cutting tool material: mold steel Cr12Mov(=D2 steel, with one million times punching/cutting life), Heat treatment to HRC58-62 degree

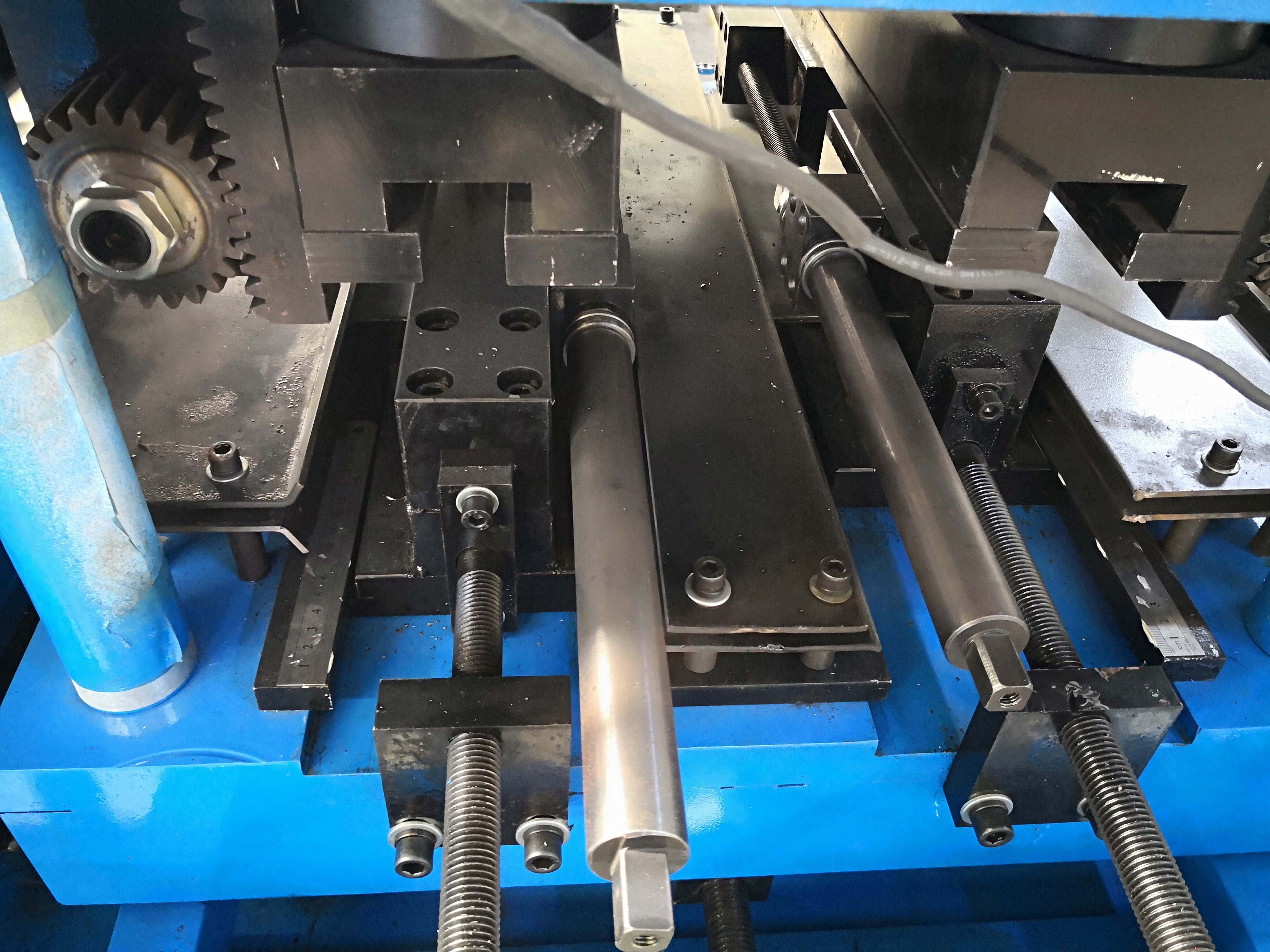

3-cylinders hole punching system for punching both on web and flange:

provide the Gear setup for UP/Down Action to act with Gear

The base of punching station are on proper lead screw for easy to take the punching stations out for punch and die change, and add the measuring scale for easy adjustment

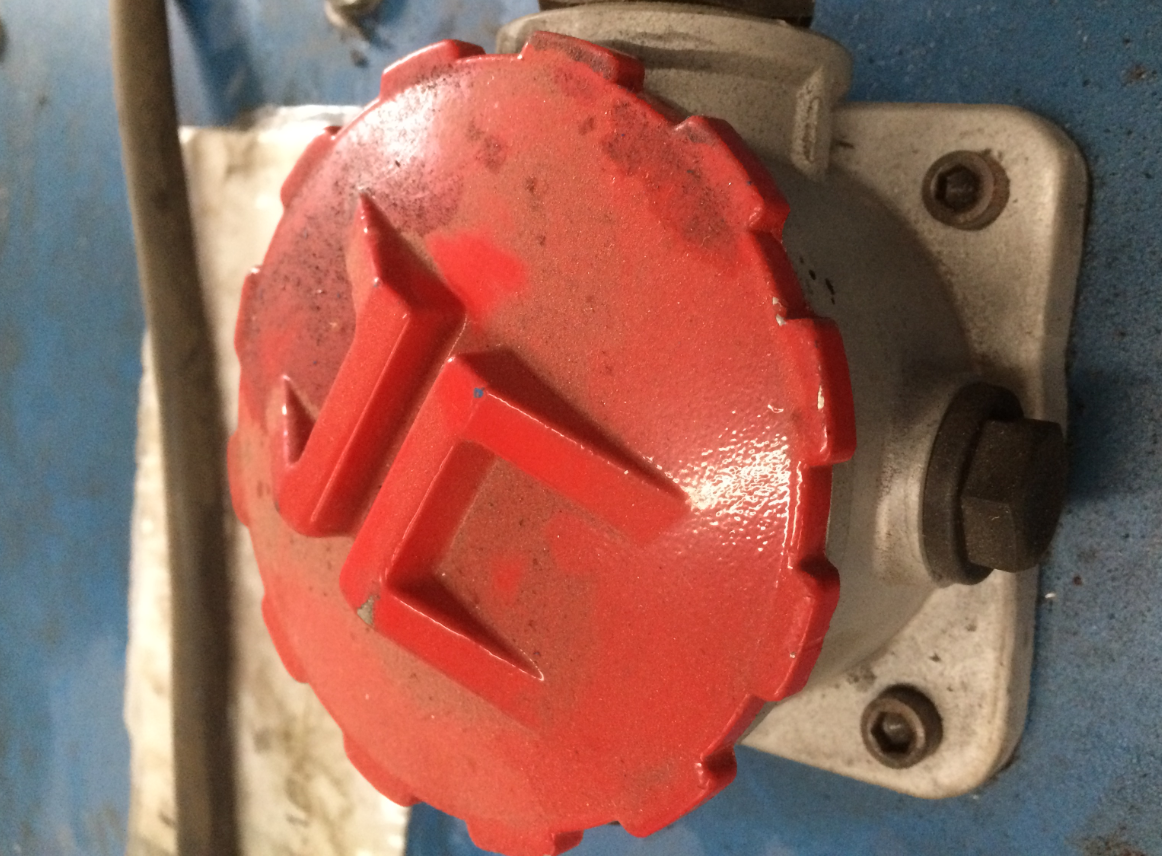

The hydraulic system with oil filter for the oil filtration,to ensure the circulated oil is clean and lengthen the life of hydraulic system .(See the picture below)

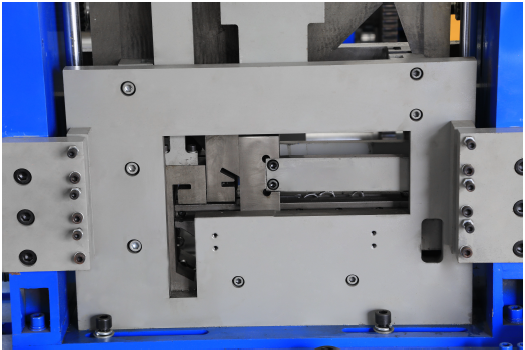

Plus our PATENTED hydraulic UNIVERSAL post-cutting device(NO NEED TO CHANGE cutting die for different size like traditional purlin machine), which make the cut profile looks better

4) PLC Control System

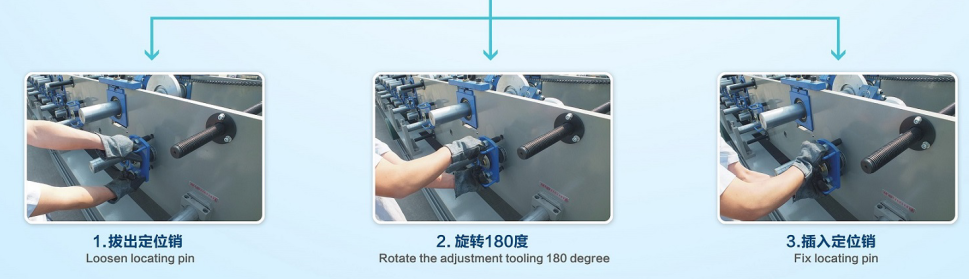

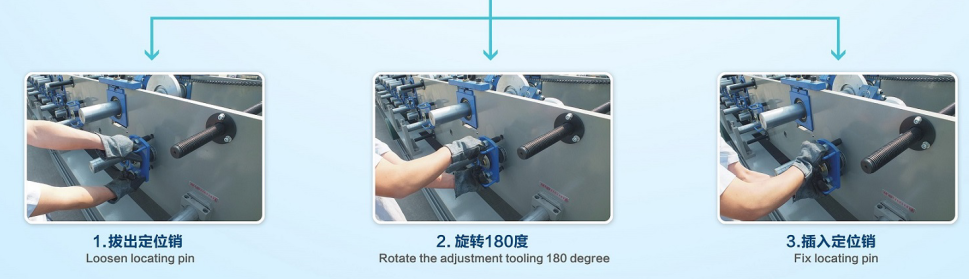

Interchange between C purlin and Z purlin: manually changing with following 3 SIMPLE steps:

But from C75-300 or Z120-300, change size by PLC system automatically: changeover by just press keys on touch screen

Control the quantity and punching, cutting length automatically

Combined with: PLC, Inverter, Touch Screen (big size 7inch for easy operation, both in English and Chinese language), Encoder, etc

Cut-to-length tolerance≤±1 mm

Control Voltage 24V

5) Exit rack:

Un-powered, with rollers on it for east movement,2 units x 3m length

V. Machine Picture(just for reference)

1.Feeding material side view:

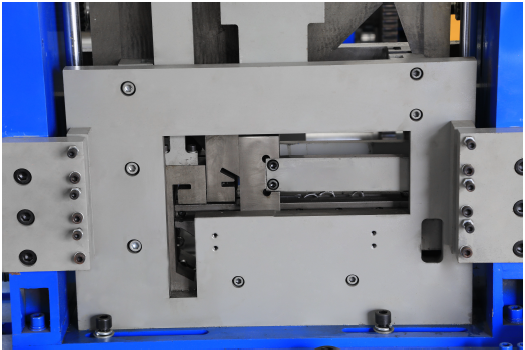

2.Inside view:

3)Universal post-cutter side view:

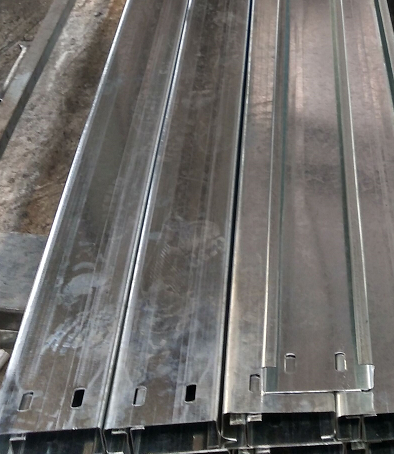

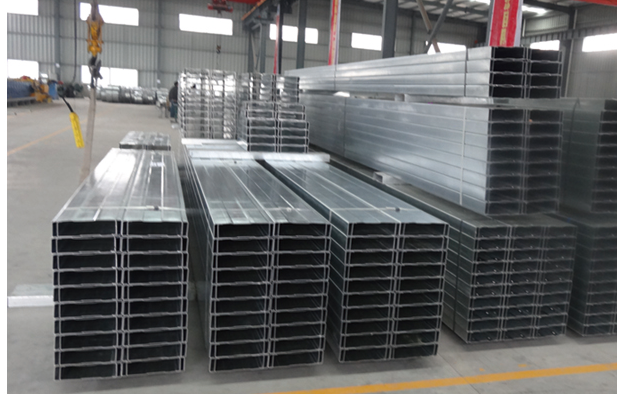

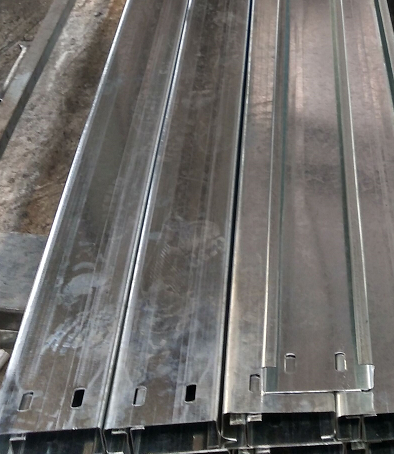

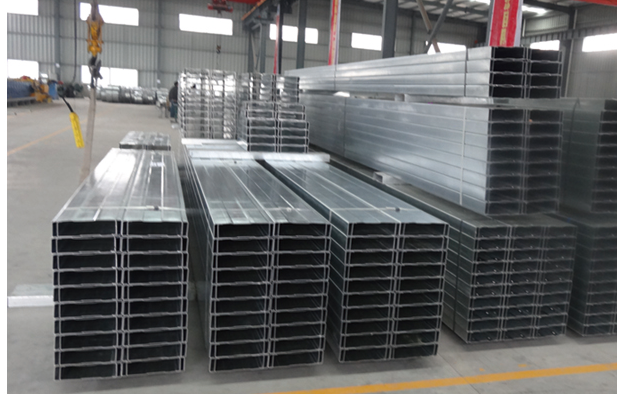

4)Machine produced C Purlins

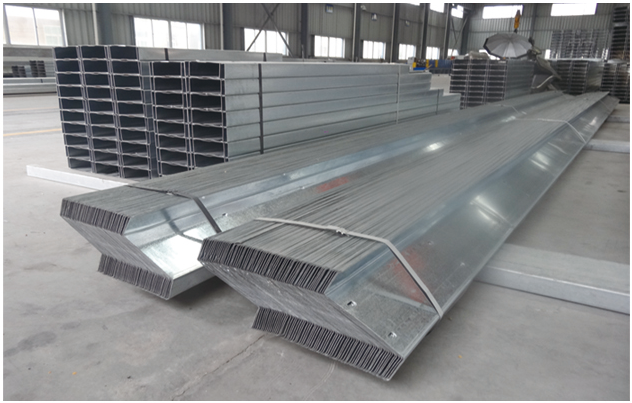

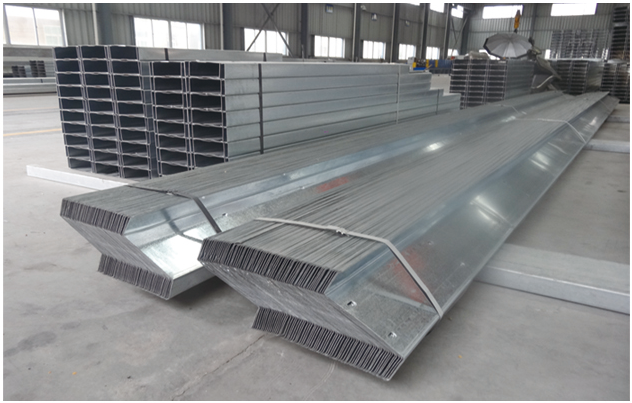

5)Machine produced Z Purlins

VI. Quick-Change type CZ Purlin Roll Forming Machine Video

http://www.rollformingmachinerychina.com/quick-change-cz-purlin-roll-forming-machine_n97