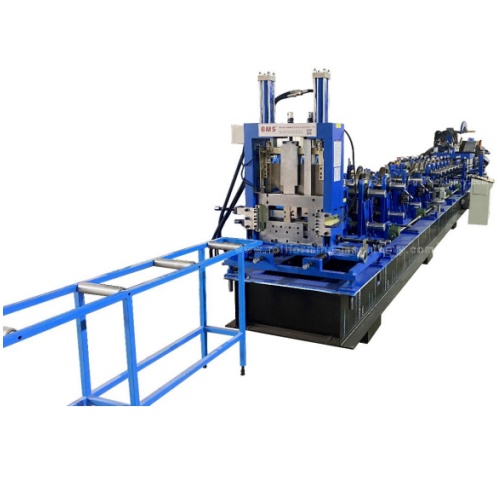

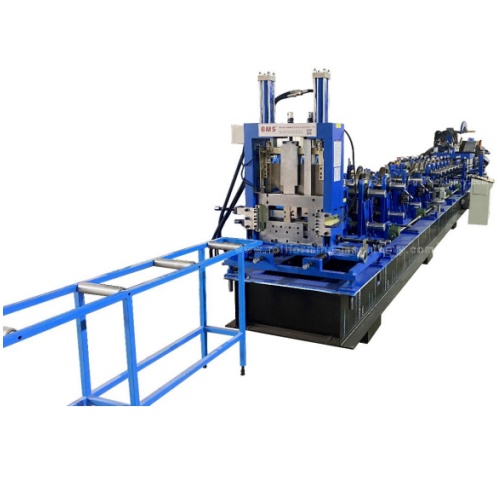

A cold CZ purlin roll forming machine is a machine that continuously bends sheet metal such as coils and strips through a continuous multi-roll forming station to form a metal processing technique for specific cross-sectional profiles. For many novices, using a CZ purlin roll forming machine can be a learning curve. This article will describe the preparatory operations that should be performed before using a CZ purlin roll forming machine.

Here is the list of contents

Step 1 - Place the machine

Step 2-Fill hydraulic oil

Step 3 - Connect the power cord

Step 4 - Place the material coils

Step 5 - Check the machine thoroughly

Step 1 - Place the machine

Before using a CZ purlin roll forming machine, you need to make sure that you place the machine in the correct position, which is a necessary prerequisite for using a CZ purlin roll forming machine. You can check that the machine is placed in the correct position by doing two things.

Whether the machine position is on a horizontal line.

Whether the uncoiler is placed about 2-3 meters in front of the machine.

You must make sure that the CZ purlin roll forming machine is placed correctly before you can start using it, otherwise, the machine is prone to malfunction during operation due to tilting, etc.

Step 2-Fill hydraulic oil

The CZ purlin roll forming machine is driven by hydraulic oil. Before running, you need to make sure that there is enough hydraulic oil in the mailbox of the CZ purlin roll forming machine. Otherwise, the machine is easy to run and abort due to insufficient oil, thus affecting the efficiency of production and processing. The following are the steps to refill the hydraulic oil.

Open the hydraulic station oil tank cover.

Filling the tank with hydraulic oil No. 46 or No. 68.

The oil volume should be at least 75% of the tank size, but not more than 90%

Step 3 - Connect the power cord

How to connect the power supply of the CZ purlin roll forming machine before making preparations for safe work, to ensure that the working environment is safe and there will be no leakage and power failure. Next, open the PLC cabinet door and connect the three fire wires labeled L1, L2, and L3 to the L1, L2, and L3 terminals inside the PLC cabinet. Finally, connect the ground wire marked PE to the PE terminal of the control cabinet.

Step 4 - Place the material coils

Once the CZ purlin roll forming machine is ready for operation, it is time to load the material. It is important to note that after placing the material steel coil into the uncoiler, lock the brake and wait until all steps are ready before starting the machine.

Step 5 - Check the machine thoroughly

Inspect the machine in the following ways.

l Check whether there are any abnormal items in the machine.

l Check the machine fasteners for looseness.

l Check the transmission system for abnormal objects.

l Check the transmission shaft for adequate lubrication.

l Check the cutting blade fasteners for looseness.

l Check whether the cutting blades are sufficiently lubricated

l Check whether the hydraulic system is normal.

l Check whether the hydraulic system connections are loose.

l Check whether the sliding of the manual pre-cutting knife is normal.

l Check whether the counting wheel rotation is smooth.

l Check whether the lines in the control cabinet are loose

Xiamen BMS Group was originally established in 1996. We have 8 factories and 20 years of experience in the industry. We understand the special requirements of customers in different countries and regions and are confident in the quality and accuracy of our products. Our products have been exported to more than 80 countries and regions, including Korea, the UK, France, the USA, Canada, etc. We guarantee the safety of your money and business. If you are interested in our products and want to get a product quote, welcome to contact us!