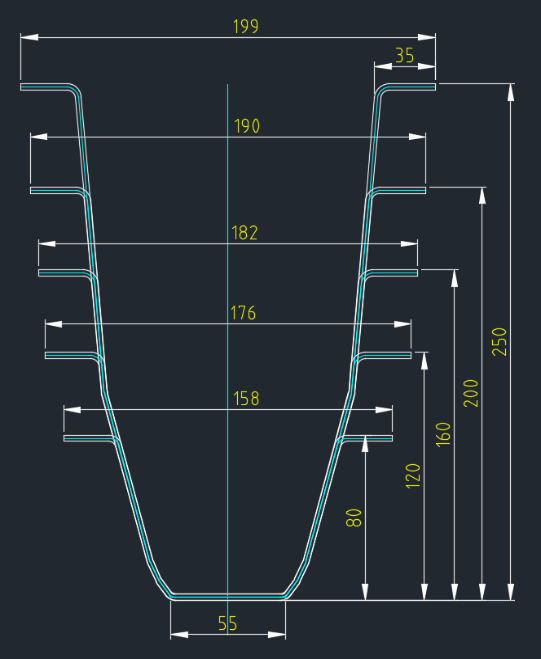

Specification of

Roll Forming Machine for Omega profile

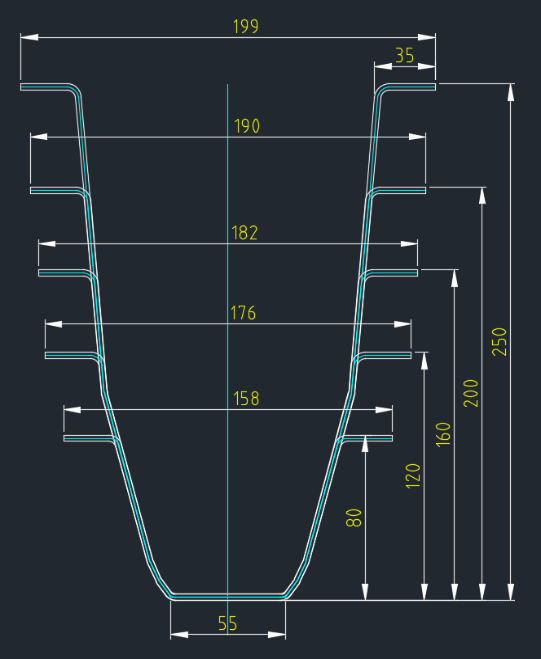

Ⅰ. Profile Drawing

Internal Radios of plate bend:3mm

Ⅱ. Material:

Material Thickness: 1.5~3.0mm

Applicable material: S320GD and S350GD galvanized steel coils

Ⅲ.Machine Components

1) Hydraulic Decoiler: one set 10 ton

Hydraulic system expand coil inner hole, Pump motor: 3KW

Frequency Inverter to regulate turning speed, Motor: 7.5KW

With electric control cabinet, motorized,

Max. feeding width: 640mm, Coil ID Range : 510+/-30 mm.

Max capacity: 10Tton, with hydraulic holding arm, hydraulic loading car with travel. Coil carriage railing length.3000mm

Coil car: Forward/backward stroke of coil car max 3000mm

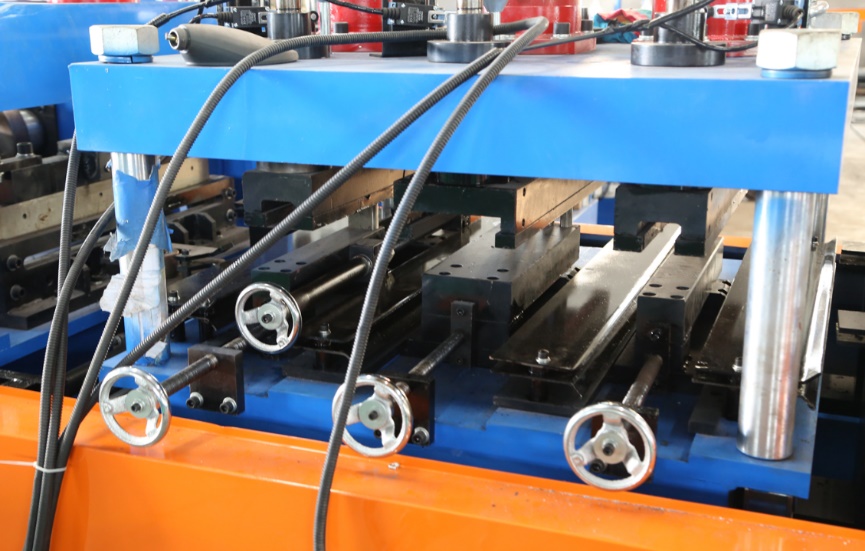

2)Cold Rolling Mill:

a. With feeding material guide and leveling device, with 7 straightening rollers (Up 3 rollers 4 down rollers), straightening shaft diameter=ф95mm,precision machined

b. Three cylinders hole pre-punching system:

With capacity for 2 holes of 30x20 in each press,

Manual adjustment of the distance between holes (trasversal)

Longitudinal distance between holes programmable in roll forming line.

Punching pins material: Cr12Mov (=D2 steel)

Single cylinder hydraulic pre-cutting system:

Hydraulic pre-shearing device,

Cutting tool material: Cr12Mov (=D2 steel), Heat treatment

Hydraulic motor: 11KW (China brand)

c. body frame made from 450# H type steel by welding;

Rollers manufactured from tooling steel Cr12(=D3 steel), precision machined, heat treatment;

Shafts manufactured from 45#,Shafts Diameter=ф90mm/ф75mm, precision machined

Gearbox driving , 24-step to form

Main Motor=22KW*2 normal motor (not servo motor)

Size change motor: 0.75KW x 2pcs (with China brand)

Forming speed approx.. 8m/min considering 5 meters profiles with 3 stops for punching and 1 for cutting

QUICK-CHANGE Size design, each size change in 5-10minutes (No need to change rollers or spacers like traditional old style machine which takes over 1-2hours for each production size changing).

3) Patented Universal Hydraulic Post Cutting device:

Hydraulic Post cut, stop to cutting, with blanking cutting;

Post-cutter and pre-cutter used the same hydraulic motor

3-blade type, adjustment for different size

Cutting tool material: Cr12Mov (=D2 steel), Heat treatment

4) PLC Control System

Control the quantity, cutting length automatically

Combined with: PLC, Inverter, Touch Screen (both English and Chinese language), Encoder, etc

PLC: Siemens brand

Inverter: Schneider Electric brand

Touch Screen: Siemens brand

Encoder: Omron brand (Japan)

Cut-to-length tolerance≤±1 mm

Control Voltage 24V

5)Exit rack:

6 meters automatic offloading table, the air source will be provided by the buyer

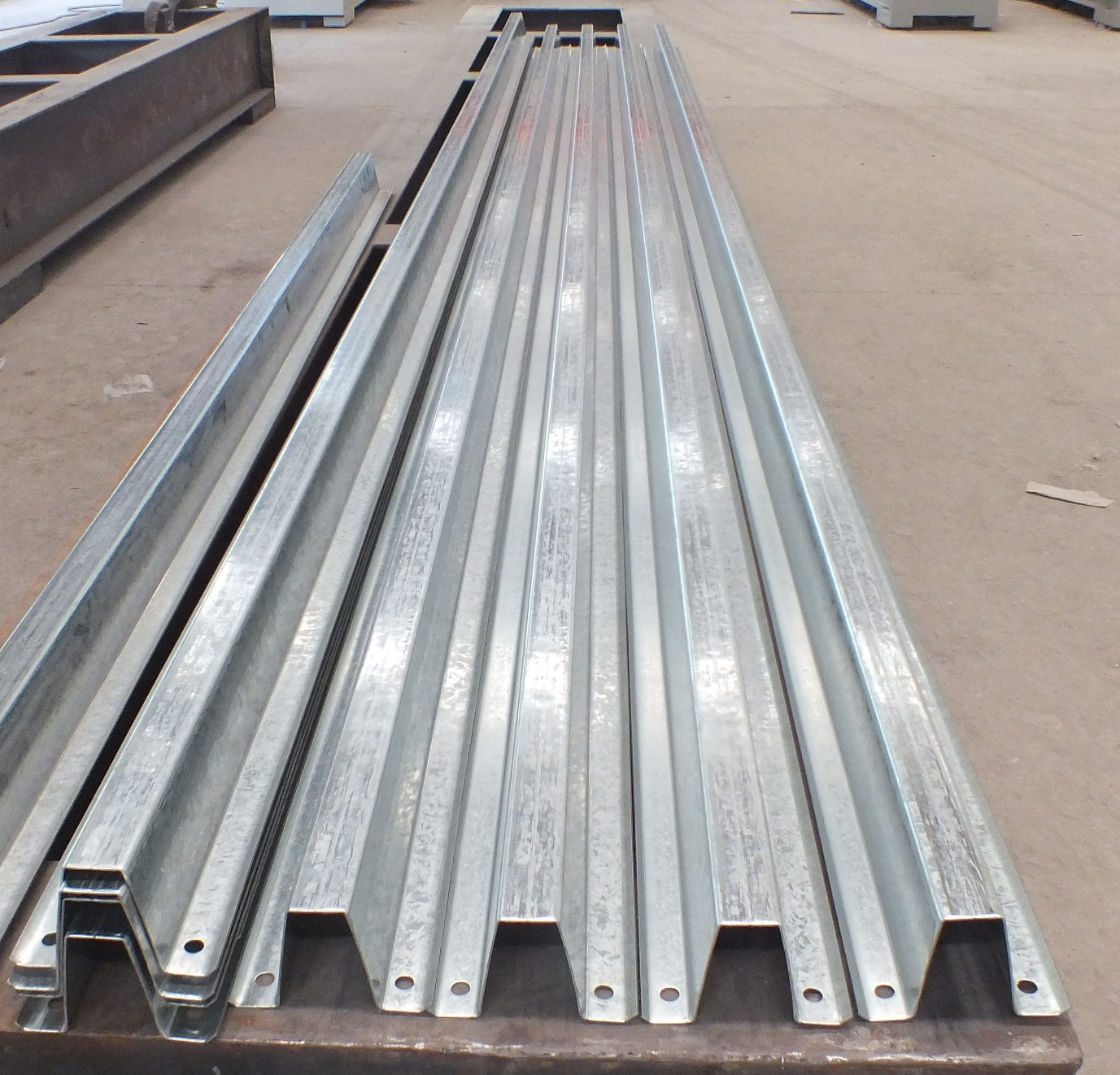

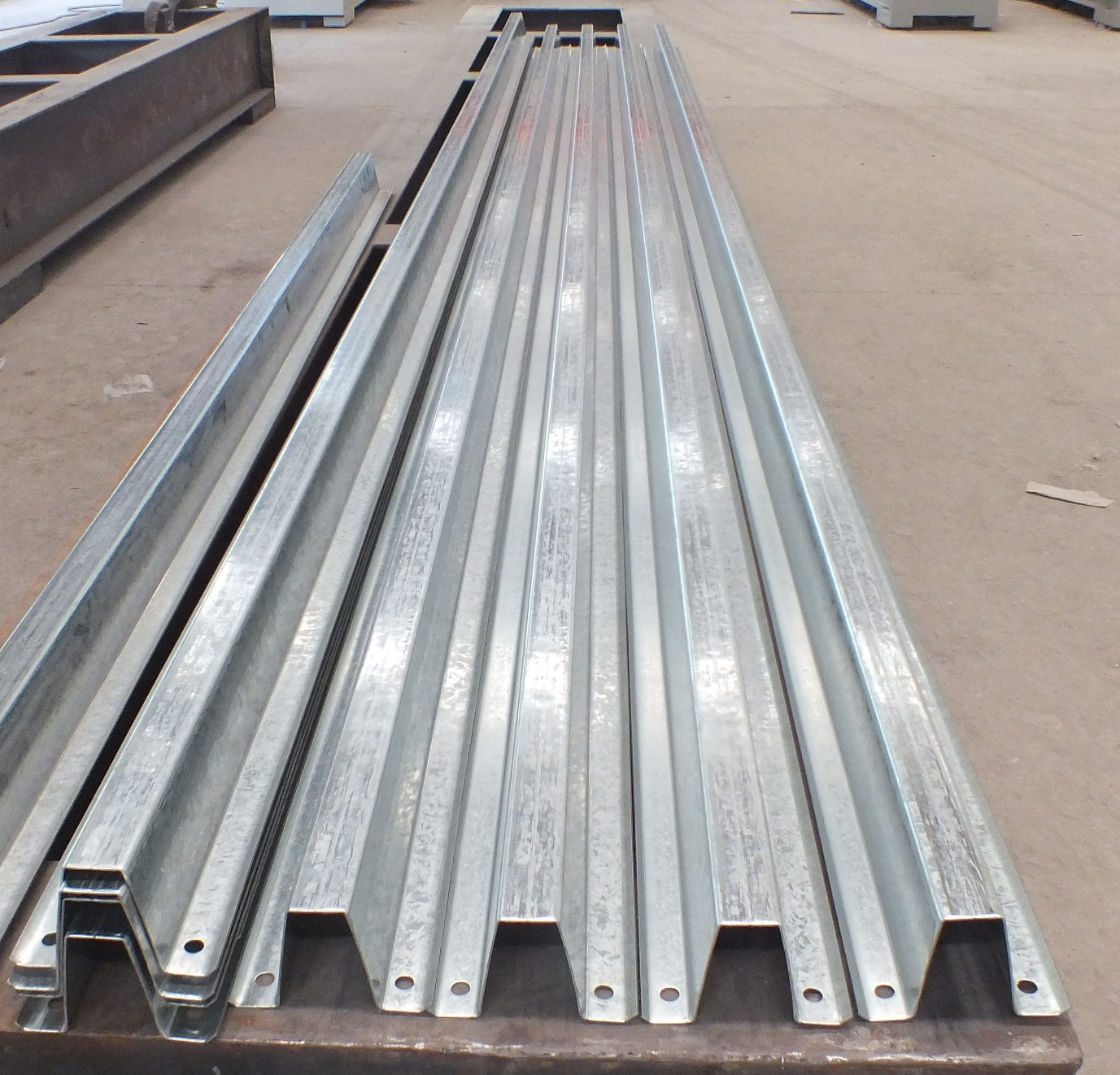

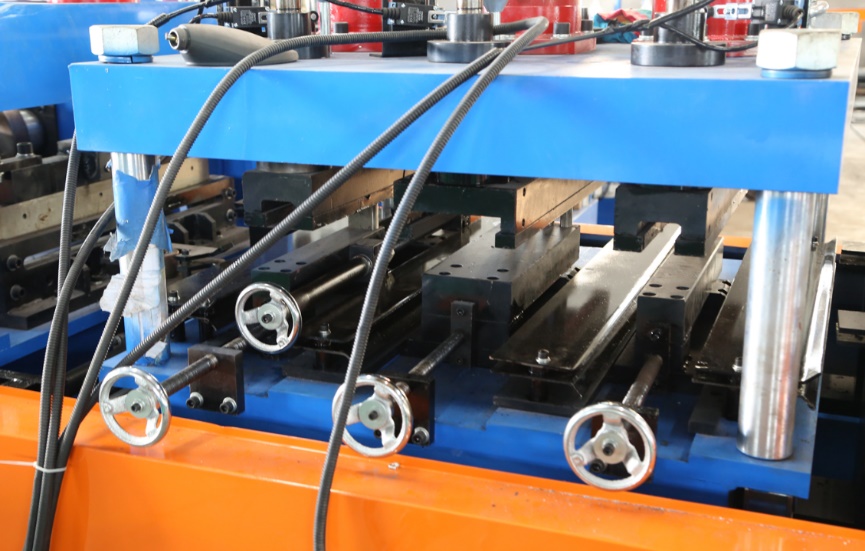

Ⅳ. Machine Picture(just for reference)