You should pick a reliable metal roofing roll forming machine. Make sure it fits your business goals and what you need to make. Many companies buy a metal roof roll forming machine to save money. They also want to make more products, provide materials to other builders, work faster, and outperform their competitors. Quality is the most important factor when selecting a metal roof making machine. A solid build, a trusted manufacturer, and long-term support enable you to produce strong metal roofs. Choosing a roof panel machine for your project means you must closely examine roll forming features and roofing roll formers. BMS Machinery offers you options for creating reliable metal roofing that you can trust.

Key Takeaways

Know what kind of metal roofing you need. Think about your business goals and the panels you want to make.

Pick the panel type that fits your project. Machines make different styles, like standing seam or corrugated panels.

Think about how much you need to produce. Choose a machine that matches your job size, big or small.

Make sure the machine works with your metal. Check if it can use metals like Galvalume steel or aluminum.

Decide how much automation you want. Choose manual, semi-automatic, or fully automatic machines for your work style.

Look for machines with quality control features. AI sensors help keep standards high and waste low.

Check if the maker has a good reputation and support. A strong warranty and helpful customer service are important for long-term use.

Get several quotes and read reviews. Comparing choices helps you find the best machine for your needs and budget.

Define Your Metal Roofing Needs

You need to know your business goals before picking a roof panel machine. Reliable metal roofing starts with a good plan. Think about what you want to make and how you want to grow. Look at your business plan, the panels you want, and the materials you will use. This helps you pick the right machine. It also makes sure your roof panel machines work well.

Panel Types for Reliable Metal Roofing

There are many kinds of metal roof panel machines. Each machine does something different. Some make standing seam roofing panels. These panels are strong and keep water out. Other machines make corrugated or ribbed panels. These are used for homes or big buildings. If you want to do big jobs, use a commercial roof panel roll forming machine. It can make lots of panels and many styles. Portable machines are good for small jobs or working at the job site. When you know what panels you need, you can pick the right machine. BMS Machinery can make special machines for any panel type. This helps you give your customers what they want.

Production Volume and Workflow

Think about how many roof panels you need to make. If you need a lot, you need a fast machine. It should run for a long time. If you do small jobs, you need a machine that is easy to change. You can make different sizes with it. A good system keeps your work smooth and fast. BMS Machinery has machines for big factories and small shops. You can pick a machine that fits your work and helps you reach your goals.

Material Compatibility

Steel, Aluminum, and Other Metals

The metal you use matters when picking a machine. Most machines work with Galvalume steel or aluminum. Galvalume is steel with a special coating. It is strong and does not rust easily. Aluminum comes in many thicknesses. It is used for homes and big buildings. Make sure your machine can use the metal you want. BMS Machinery makes machines for many metals. This helps you make strong metal roofs every time.

Coating and Finish Options

Coatings and finishes protect your roof panels. They also make them look nice. Some machines can use special coated coils. These are good for the environment and look good. Decide if you need a machine for painted, galvanized, or other coated metals. This choice changes how your roof panels look and last. BMS Machinery can help you pick machines for many coatings and finishes. This makes sure your products are what people want.

Tip: Always talk to a roofing expert or engineer before you choose. They can help you pick the right thickness and spacing for your roof panels. This makes sure your building can hold the materials you pick.

Factor | Description |

Business Strategy | Shows your goals for making metal roofs. |

Panel Type | Helps you pick the right roof panel machine. |

Material Compatibility | Makes sure your machine works with steel or aluminum. |

Production Volume | Lets you choose a machine for your needs. |

Coating and Finish | Changes how long your roof panels last and how they look. |

BMS Machinery can make roof panel machines for any panel or metal. You get a machine that fits your business. This helps you give your customers strong metal roofs.

Compare Metal Roof Roll Forming Machine Options

Stationary vs. Portable Rollforming Machine

You need to pick between stationary and portable machines. Each type works best for different jobs. Stationary machines stay in one spot. They are used in factories or workshops. Portable machines can move to different places. You can bring them to the building site.

Here is a table that shows the main differences:

Feature | Portable Roll Formers | Stationary Roll Formers |

Size | Compact and movable | Larger heavy-duty production machines |

Output Capacity | Lower output capacity | Higher output capacity |

Application | Used at construction site | Used in manufacturing facilities |

Profile Range | Form limited profiles | Form wide range of profiles |

Operation | Manual operation | Automated operation |

Portable machines are good for small jobs. They help you save time and money. Stationary machines are better for big factories. They make more panels every day. You get more power and more choices. Both types help you make strong metal roofs. You need to pick the machine that fits your work.

Automation Levels

Roof panel machines have different automation levels. You can choose manual, semi-automatic, or automatic machines. Automation changes how fast and easy your work is.

Manual, Semi-Automatic, Automatic

Manual machines need you to do most steps. You feed the metal, set controls, and cut panels by hand.

Semi-automatic machines help with some steps. You might feed the metal, but the machine cuts or shapes panels for you.

Automatic machines do almost everything. They feed, form, and cut panels with little help.

Modern machines often have automated systems. Automation keeps the quality the same every time. It also makes work faster and easier.

"A rollforming line with sensors can record process data. You can use this data later. It helps you set up the machine faster. You make high-quality panels every time."

If you want to make many panels quickly, automatic machines are best. They save time and lower labor costs. You get reliable results every time.

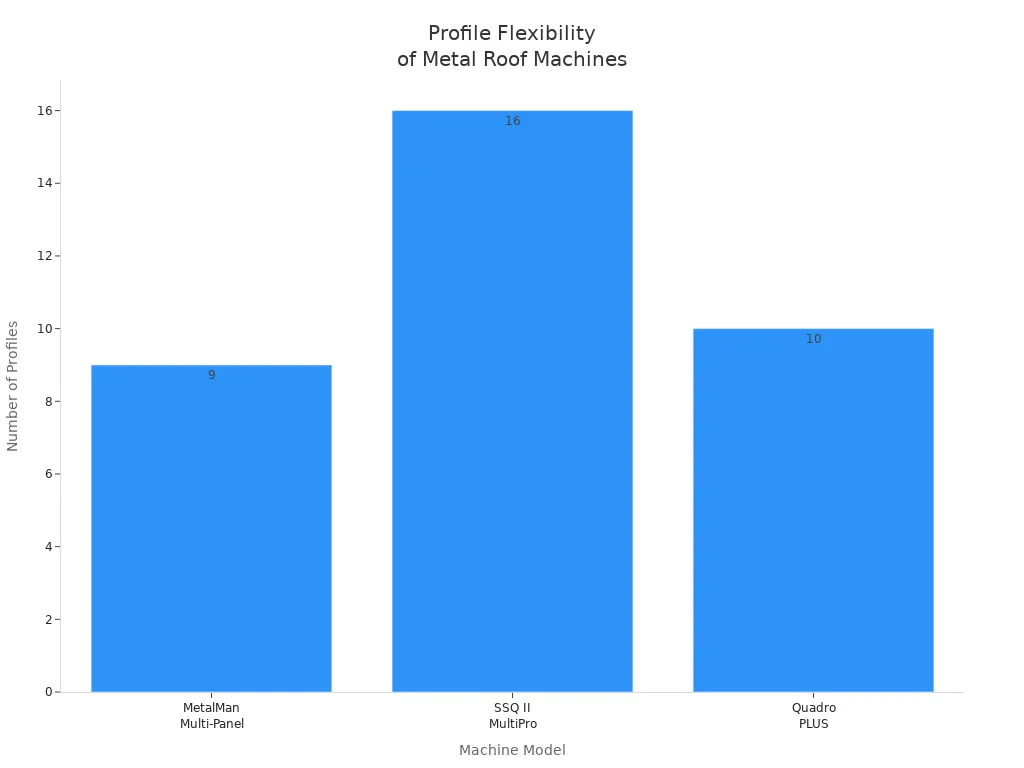

Profile Flexibility and Quality

Profile flexibility means your machine can make different shapes and sizes. Some machines only make one kind of panel. Others can switch between shapes with special tools. If you want to serve many customers, you need a flexible machine.

Here is a table showing how many profiles some machines can make:

Machine Model | Number of Profiles | Profile Types |

MetalMan Multi-Panel | 9 | Standing seam profiles (various) |

SSQ II MultiPro | 16 | Mechanical lock seams, snap-lock profiles, flush wall/soffit panels, dual-function 2” profile, board & batten profile |

Quadro PLUS | 10 | Optional profiles with appropriate cassettes |

Pick a machine that gives you both flexibility and quality. A good machine switches shapes fast. It keeps every panel strong and straight. This helps you meet customer needs. You build a good reputation for quality. Reliable machines help you make the best metal roof every time.

BMS Machinery Solutions

You want a metal roof roll forming machine that works well every time. BMS Machinery gives you many options to pick from. You can find a rollforming machine for a factory or a job site. BMS Machinery uses new technology from Taiwan. This helps you make strong roof panels with great accuracy.

BMS Machinery makes machines that follow world rules. You get ISO9001 and European CE approval. These show your machine is safe and high quality. BMS Machinery checks every rollforming machine with special tools. Tools like Rockwell Hardness Testers and Tachometers test the parts. You can trust your metal roof making machine will last many years.

You can pick from many products. BMS Machinery has roof panel forming machines, purlin machines, and more. You can make different roof profiles for homes, factories, or big buildings. Automated roof panel machines help you work faster. You save time and make fewer mistakes. You can change profiles quickly. This helps you give customers what they want.

North American customers say BMS Machinery machines are quiet. You can work in a busy shop without loud sounds. The machines make roof panels that look nice and stay strong. You can count on good quality every time.

Here is a table that shows some features you get with BMS Machinery:

Technology/Feature | Description |

Taiwanese Technology | High quality and precision for roof panels |

ISO9001 & CE Certification | International standards for safety and reliability |

Testing Equipment | Rockwell Hardness Tester, Tachometer, Roundness Measuring Instrument |

Customer Feedback | Quiet operation and high satisfaction in North America |

Product Range | Roof panel forming machines, purlin machines, and more |

You can use automated roof panel machines to make more panels. You get the same good roof panels every time. BMS Machinery helps you grow your business. You can make more roof panels and help more customers. You get a rollforming machine that fits your goals.

Tip: Ask BMS Machinery about custom rollforming solutions. You can get a machine that fits your exact roof panel needs.

You can trust BMS Machinery for good rollforming. You get new technology, strong machines, and help from experts. Your roof panels will be high quality every time.

Evaluate Production Capacity and Specifications

Speed and Throughput

You should see how fast your roof panel machines work. Speed and throughput tell you how many panels you can make in a certain time. If you want your business to grow, pick a machine that makes lots of panels. Some machines make 4-5 meters of panels each minute. If you use a servo motor, you can make 8-9 meters per minute. Some advanced machines make 25-30 meters per minute. Most rollforming machines work between 8 and 15 meters per minute.

Normal speed: 4-5 meters per minute

Servo motor speed: 8-9 meters per minute

Advanced equipment speed: 25-30 meters per minute

Forming speed range: 8-15 meters per minute

If you need to make many panels fast, automated machines help you do that. You can make more panels and keep your work moving. Always pick a machine speed that fits your business. This helps you finish jobs on time and keeps your customers happy.

Tip: Fast roof panel machines save time and help you do bigger jobs.

Sheet Size and Thickness

You need to know the sheet size and thickness before picking a machine. These details change how well your roof panels work. If you use narrow sheets, you can make panels up to 800mm wide. Standard sheets let you go up to 1250mm. Wide sheets can be up to 2100mm. For thickness, light gauge sheets are 0.35mm to 0.8mm. Regular gauge sheets are 0.8mm to 2.0mm. Heavy gauge sheets are more than 2.0mm thick.

Specification Type | Details |

Sheet Width | Narrow width up to 800mm |

| Standard width up to 1250mm |

| Wide width up to 2100mm |

Sheet Thickness | Light gauge 0.35mm to 0.8mm |

| Regular gauge 0.8mm to 2.0mm |

| Heavy gauge over 2.0mm |

Pick a machine that matches your sheet size and thickness. This helps you make strong panels for every job. If you use the wrong machine, your panels might not last long. Always check sheet size and thickness before you start making panels. This keeps your work fast and your panels good.

Quality Control Features

You need quality control features to make sure your panels are strong. Good machines use AI-driven sensors to find problems right away. These sensors help you waste less material and make better panels. Advanced servo motors help you control speed and save energy. They also make sure the metal moves right and forms well.

Quality Control Feature | Description |

AI-Driven Quality Control | AI sensors find problems as you work, so you waste less. |

| They help you make better panels and throw away less. |

Advanced Servo Motor Integration | Servo motors help you control speed and save energy. |

| They make sure the metal moves right and forms well. |

If you use machines with quality control, you can make more panels and keep them strong. Always check if the machine has these features before you buy. This helps you build a good name and keeps customers coming back.

Note: Quality control features help you stop mistakes and keep your panels strong.

BMS Quality Assurance

You want your roofs to last a long time. Quality assurance helps you reach this goal. BMS Machinery checks every machine before it leaves the factory. This makes sure your machine can make lots of roof panels. Your panels will be strong every time.

BMS Machinery follows rules from around the world. Each machine gets European CE certification. This means your machine is safe and works well. You can trust it for many years. BMS uses special tools to test each part. These steps help you get great results for your roof jobs.

You should know how BMS checks quality at every step. The company uses four steps to manage quality. Each step keeps your machine working well and helps you reach your goals.

Quality Management Process | Description |

Incoming Quality Control (IQC) | Checks new materials and fixes problems |

In-Process Quality Control (IPQC) | Watches staff and keeps machines safe |

Final Quality Control (FQC) | Tests how the machine works and checks packaging |

Outgoing Quality Control (OQC) | Checks packing lists and how the product looks |

You see the results of this process every day. When you use a BMS machine, you get steady work. Your roof panels are straight and strong. You do not waste time fixing errors. You can finish more jobs and help your business grow.

BMS Machinery also helps you keep your machine working well. The company gives you support and training. You learn how to use your machine the right way. If you have questions, you get help fast. This support helps you make more panels and keep them strong.

Note: Quality assurance is not just a promise. It is a system that protects your business and helps you give your customers the best roof panels.

You can trust BMS Machinery for good machines, strong production, and roof panels that meet high standards.

Budget and Total Cost of Ownership

Initial Investment in Metal Roof Making Machine

You need to think about your budget before you buy a roof panel machine. The first thing to check is how much money you need at the start. This means the price of the machine, the cost of raw materials, and other setup costs. You also need to think about space for your factory, workers, licenses, and bills for things like water and power. Here is a table that shows how much it might cost to start making roof panels:

Category | Estimated Cost Range |

Machinery Costs | $75,000 - $600,000 |

Raw Materials | $15,000 - $65,000 |

Factory Space | $12,000 - $60,000 annually |

Staffing Needs | $100,000 - $200,000 (annual) |

Licenses and Permits | $1,300 - $6,000 |

Utilities and Overhead | $3,000 - $13,000 |

Total Estimated Costs | $205,300 - $1,050,000 |

You should look at these numbers and compare them to your business plan. This helps you know how much money you need to start making roof panels. You can pick a machine that matches your goals and your budget.

Maintenance and Spare Parts

You have to keep your roof panel machine working well. Maintenance and spare parts are important if you want your business to last a long time. You should save some money for regular checkups and repairs. Most companies spend about 2 to 4 percent of the machine’s value each year for maintenance. Tooling and things you use up usually cost 1 to 3 percent of the machine’s value. If you use thick steel or change profiles a lot, these costs can go up.

Save 2 to 4 percent of the machine’s value for yearly maintenance.

Set aside 1 to 3 percent for tooling and things you use up.

Costs can be higher if you use strong steel or change profiles often.

Regular maintenance helps your machine work smoothly. You will not lose time, and your roof panels will always be strong.

Energy Efficiency and Operating Costs

Energy efficiency changes how much it costs to run your machine. If you use a machine that saves energy, you can use up to 30 percent less power. Some companies have used 40 percent less energy after making their machines better. Big factories that use energy-saving machines can cut their yearly energy bills by 30 percent. This means you make more money and your business can grow.

Evidence Type | Description |

Energy Savings | Optimized machinery can decrease energy consumption by as much as 30%. |

Case Study | A manufacturer achieved a 40% decrease in energy consumption after efficiency enhancements. |

Profitability Impact | High-volume production lines saw a 30% annual reduction in energy costs, boosting profitability. |

You should try to find machines that use less energy. These machines help you spend less money and make your roof panels cheaper. You can use the money you save to buy better materials or make your business bigger.

Tip: Ask your supplier about machines that save energy. You can save money and help the planet too.

BMS Value Proposition

You want your roof to last a long time. You need a machine that makes strong roof panels. This also helps your business run well. BMS Machinery gives you more than just a machine. You get a partner that helps you save money. Your investment is safe for many years.

BMS Machinery knows your budget is important. You do not want to spend too much money at first. You also do not want big costs later. BMS offers good prices. You get a high-quality machine without paying extra. This helps you start making roof panels with confidence.

You get help before you buy your machine. BMS gives you technical advice. You can talk to experts about your roof project. They help you pick the right machine. This means you do not waste money on things you do not need. You get a machine that fits your business and your budget.

BMS can change each machine for your needs. You can ask for special firmware or protocol changes. This makes your machine work better for your roof panels. You do not have to change how you work. You save time and make your work faster.

If you use a BMS machine, you get fast help when there is a problem. You do not wait long for repairs. This keeps your roof panel work on track. You do not lose money because of delays.

BMS Machinery helps you for many years. You get help with fixing and upgrading your machine. Your machine works well for a long time. You do not get surprise costs. You can focus on making roof panels and growing your business.

Here is a table that shows how BMS Machinery helps your roof panel work:

Feature | Description |

Pre-sales technical consultation | Helps in understanding project requirements and ensuring proper solutions. |

Custom firmware and protocol adaptation | Tailors the system to specific needs, enhancing functionality and efficiency. |

Rapid troubleshooting and diagnostics | Minimizes downtime, leading to cost savings in operations. |

Long-term lifecycle support | Ensures ongoing assistance and maintenance, protecting the investment. |

Tip: You can ask BMS Machinery for a custom solution. You get a machine that fits your roof panel needs and your budget.

You get more than a machine. You get a team that helps you do well. BMS Machinery helps you make strong roof panels, save money, and build a business that lasts.

Manufacturer Reputation and Support

Warranty and Service

When you buy a roof roll forming machine, you want to know it will last. A good warranty gives you peace of mind. Leading manufacturers offer warranties that cover parts and service for one to five years. Some companies give a five-year limited warranty, while others offer one or two years. These warranties show that the company stands behind its machines. You should always ask what the warranty covers before you buy. Good service means you get help fast if your roof machine stops working. You want a company that answers your questions and sends parts quickly. This keeps your roof production running and protects your investment.

Here is a table that shows what top manufacturers offer:

Manufacturer | Warranty Details |

Englert, Inc. | Five-year limited parts and labor warranty on roof panel machines |

Roll Former Corporation | One-year parts warranty from the date of receipt |

Schlebach Maschinen Gmbh | 12-month guarantee from the date of purchase |

Knudson Manufacturing, Inc. | Two-year parts warranty for original purchasers |

A strong warranty and good service help you trust your roof machine for many years.

Training and Technical Support

You need to know how to use your roof machine the right way. Training helps you learn how to set up, run, and fix your machine. Many companies offer training at their factory or at your shop. You can get in-house training, on-site training, or extra lessons for special controllers. This training covers setup, operation, and maintenance. When you understand your machine, you make better roof panels and waste less material.

Technical support is also important. You want experts who can answer your questions and help you solve problems. Good support helps you feel confident. You can talk to technicians who know the machine and can guide you step by step. This support keeps your roof production smooth and helps you avoid mistakes.

Here are some types of training you might get:

Training at the manufacturer's facility

On-site training at your shop

Lessons on machine operation and maintenance

You should always choose a manufacturer that offers strong training and support. This helps you get the best results from your roof machine.

Customer Reviews and Case Studies

Customer reviews help you see how a roof machine works in real life. You can read what other people say about the machine's quality and support. Good reviews show that the machine makes strong roof panels and that the company helps customers after the sale. Case studies give you real examples of how the machine works in different jobs. You can learn about on-time delivery, fast response to problems, and how easy it is to get spare parts.

When you look at reviews, check for these things:

Did the machine meet the customer's needs?

Was the company easy to reach for help?

Did the roof panels turn out strong and straight?

Was it easy to get spare parts?

You can also ask for technical drawings and talk to the company's engineers. This helps you know if the machine will fit your roof project. Good support and happy customers show that you can trust the manufacturer. BMS Machinery has many customers around the world who share their good experiences. You can feel confident when you choose a company with strong reviews and real case studies.

Tip: Always ask for customer references before you buy a roof roll forming machine. This helps you make a smart choice.

BMS Machinery Global Reach

You want a roof roll forming machine that works well anywhere. BMS Machinery gives you this trust. The company started in China and now helps people all over the world. You can find BMS machines in more than 80 countries and regions. This means BMS Machinery knows about many markets and roof needs.

You can trust BMS Machinery because big companies use their machines. Some famous clients are China State Construction, Tata Bluescope Steel, and the Philsteel group. These companies use BMS machines for important roof jobs. You know BMS Machinery always gives high quality.

BMS Machinery has eight factories and six machining centers. This means the company has lots of resources. The factories use advanced technology from Taiwan. This helps you make roof panels that fit just right. You can see the good results in your roof products.

If you need help, BMS Machinery gives support in many languages. You can ask questions and get answers fast. The company has experts who can fix problems. You get training and technical help no matter where you live. This makes your roof work easier and safer.

Here is a table that shows where BMS Machinery works:

Region | Countries Served | Support Languages | Major Clients |

Asia | 20+ | Chinese, English | China State Construction |

Europe | 15+ | English, German | Tata Bluescope Steel |

North America | 10+ | English, Spanish | Philsteel Group |

Middle East | 8+ | English, Arabic | ICP Building Products |

Africa | 12+ | English, French | Xiamen C&D Group |

You get a roof roll forming machine that meets world rules. BMS Machinery has European CE certification. This means your machine is safe and works well. You can use it for roof jobs in any country.

Tip: If you want to sell roof panels or start a business in another place, BMS Machinery helps you follow local rules and quality needs.

You can see BMS Machinery at trade shows and events. The company shares new ideas and technology. You learn about the newest roof trends and how to make your work better. BMS Machinery builds a good name by helping customers everywhere.

You get more than a machine. You join a worldwide group of roof experts. BMS Machinery helps you with training, advice, and quick service. You can grow your business and make strong roof panels for any market.

Practical Tips for Final Selection

Get Multiple Quotes

Start by asking different suppliers for quotes. This helps you compare prices and features. Each quote tells you what comes with the machine and the cost. You can see which machine fits your budget and project. Some suppliers give extra services or longer warranties. Use these quotes to find the best deal. Make a list of what you need, like speed and support. Check each quote against your list. This way, you do not pay too much. You also get a machine that works for you.

Tip: Always ask for a full quote. It should include installation, training, and spare parts.

Read Reviews and Testimonials

Reading reviews gives you real stories from other buyers. You learn how people feel about their machines. Reviews show how well the machines work. Many users say their machines are better than expected. They talk about fast work and good quality. A survey says 87% of homeowners like their metal roofs. This means metal roofs last long and work well. People talk about machines that are fast and very exact. These stories show which machines make the best panels. New machines can help you work 20% faster. Reviews tell you which machines save time and money. Use these tips to pick a good machine.

Reviews show how machines work in real jobs.

Stories talk about fast and exact machines.

Users say they make more panels and strong roofs.

Most buyers are happy with their metal roofs.

Note: Reviews help you avoid mistakes. You can learn from others and pick a machine that works well.

Visit Factories or Request Demos

You should visit factories or ask for a demo before you choose. Watching the machine helps you see how it works. You can check if it fits your project. When you visit, look at the machine’s details. Check how fast it works and how much power it uses. Make sure it can use the roof materials you want. Ask about service and warranty. You need help for your machine later. Look at the space needed for the machine. Think about your needs and your budget. Check brands for strong machines and good features. Watching a demo shows if the machine is easy to use. You can see if it makes strong and straight panels.

Think about what type and size you need.

Look at your budget.

Check brands for strong machines.

Look at the machine’s details.

Ask about service and warranty.

Make sure you have space for the machine.

Tip: Ask BMS Machinery for a demo. You can see their machines make strong roof panels and get advice from experts.

Consult Industry Experts

You can make a smarter choice when you talk to industry experts. These professionals know how to match the right machine to your roof project. You get advice that helps you avoid mistakes and save money. Experts look at your business goals and help you plan for the future.

Industry experts suggest you ask yourself important questions before you buy a machine. You should think about where you will produce roof panels. Some companies make panels in a factory. Others make panels at the job site. Your role as a supplier or installer changes what you need.

You should check how a new machine will affect your project efficiency. Experts say you must know if you handle residential or commercial roof jobs. You need to decide which panel profiles you want to offer. Some profiles work better for certain buildings. You can ask about special requirements for your roof panels.

You must look at your budget. Experts help you understand pricing and what you can afford. You should check space requirements for your machine. You may need add-ons to make your roof panels stronger or more attractive.

Industry experts recommend you investigate the types of machines available from different manufacturers. You should learn about the benefits of buying from a supplier or distributor. You need to confirm if the manufacturer can deliver your machine on time. Shipping and freight costs can change your budget.

You should look for training, service, and technical assistance. Experts say you must compare warranty options among manufacturers. You need to make sure the machine has the add-ons you want. You should evaluate the reliability of the sales team.

Here is a list of questions industry experts suggest you ask:

Where will you produce roof panels?

What is your role in the project?

How will a new machine improve efficiency?

Do you handle residential or commercial roof jobs?

Which panel profiles do you want to offer?

What is your budget for the machine?

Do you have enough space for the machine?

What add-ons do you need for your roof panels?

Which machines do manufacturers offer?

Should you buy from a supplier or distributor?

Can the manufacturer deliver on time?

What are the shipping and freight costs?

Is training and technical support available?

What warranty does the manufacturer offer?

Does the machine have the add-ons you need?

Is the sales team reliable?

You can contact BMS Machinery for expert consultation. The team helps you answer these questions and guides you to the best machine for your roof project. You get support from professionals who know the industry. You make a confident choice and build strong roofs for your customers.

Tip: Always talk to industry experts before you buy a machine. Their advice helps you avoid costly mistakes and ensures your roof panels meet high standards.

You can select a reliable metal roofing solution by following these steps:

Decide which type of roof panels you want to produce.

Check your production needs for roof jobs.

Set your budget for choosing a metal roof roll forming machine.

Look at sheet sizes and features for your roof panels.

Advanced machines help you make strong roof panels with speed and accuracy. You get high-quality results and save money. Good support and training let you use your machine well and grow your roof business.

Next, you can expand your roof services, buy rib roller sets, or build a plan for new roof projects. Reach out to BMS Machinery or industry experts for help with choosing a metal roof roll forming machine. You get reliable metal roofing and support for your business.

FAQ

What is a roll forming machine?

A roll forming machine makes metal sheets into roof panels. You put metal into the machine. The machine bends and cuts the metal. This makes strong panels for roofs.

How do I choose the right machine for my business?

Think about what panels you want to make. Check how many panels you need and your budget. Make sure the machine works with your materials. Ask experts if you need help.

Can I use different metals with one machine?

Most machines work with steel and aluminum. You should check the machine’s details. Some machines can also use copper or zinc.

How much maintenance does a roll forming machine need?

You need to clean and check your machine often. Regular care keeps it working well. Plan to check it every year and change old parts.

What is the average speed of a metal roof roll forming machine?

Many machines make 8 to 15 meters of panels each minute. Some fast machines can make up to 30 meters per minute. Pick a speed that matches your work.

Does BMS Machinery offer training and support?

BMS Machinery gives training and support. You get help with setup and using the machine. Support is ready for you anywhere in the world.

How long does a roll forming machine last?

A good machine can last more than 10 years. Taking care of it helps it last longer. BMS Machinery makes machines that work for many years.

Can I customize my roll forming machine?

You can ask BMS Machinery for special features. The team can change machines for your panels and materials. Custom machines help your business do better.