A roofing sheet manufacturing machine bends metal sheets into strong panels for building. You get great results with a High Speed Roof Panel Roll Forming Machine. It does the work by itself, lowers worker costs, and keeps the quality the same. Flying cutting systems and nonstop work help you meet big orders quickly. BMS roll forming machinery is known as a good option. More people want these machines around the world. The market is growing fast. Experts think it will grow by 13.4% each year from 2025 to 2032. This is because more cities are being built and new ways of building are popular.

Key Takeaways

High Speed Roof Panel Roll Forming Machines work fast. They make panels quickly. Fewer workers are needed. This helps the job get done faster.

The flying cutting system makes clean cuts. It uses less material. This means less waste. The roofing sheets look better.

Modern machines can do many things. They use different materials. They make custom designs. This helps meet customer needs.

BMS roll forming machinery gives good support. They help with maintenance. This keeps machines working well. Customers stay happy.

Automation in roofing sheet manufacturing saves energy. It lowers costs. This is good for the environment. It is a smart choice.

How It Works

Roll Forming Process

You want roofing sheets that last long and look nice. The roll forming process helps you get both. You start with metal coils. The machine pulls these coils into rollers. Each roller shapes the metal a bit more. You end up with strong panels that look perfect. The process uses a PLC control system. You press a button, and the machine does the job. You save time and make fewer mistakes.

Here is a simple list of the main parts and steps:

Component/Step | Description |

Uncoiler | Holds and feeds the metal coil. |

Roll Forming Machine | The main part where rollers shape the metal. |

Cut-off Blade | Cuts the metal with hydraulic power. |

Collection Table | Stacks the finished panels. |

Control Box & Hydraulic Station | Controls and powers the machine. |

Workflow Steps | Uncoiling → Feeding and Guiding → Roll Forming → Cutting Off → Collection |

A High Speed Roof Panel Roll Forming Machine gives even better results. It uses smart controls and advanced rollers. You get more panels in less time. You also make fewer mistakes and waste less material.

Tip: Always check your finished sheets before packing. This step helps you avoid problems later.

Flying Cutting System

You want clean cuts and no wasted metal. The flying cutting system makes this easy. The machine cuts panels while they move. You do not need to stop the line. You get the right length every time. Hydraulic and servo cutting systems give sharp, smooth edges. You avoid rough cuts and uneven panels.

Modern machines use laser-guided alignment and AI-powered thickness checks. These features help you keep every panel the same. You get good results, even with big orders.

Here are some new features in today’s machines:

Innovation Type | Description |

Hydraulic Cutting | Makes clean, sharp cuts for good roofing sheets. |

Servo Cutting | Works best for fast, automatic lines. |

PLC Control Panels | Touchscreens make the machine easy to use. |

Energy-efficient Motors | Use less electricity but still work well. |

Laser-guided Alignment Systems | Keep rollers in the right spot for perfect panels. |

AI-Powered Thickness Monitoring | Finds small changes in coil thickness right away. |

Servo-Controlled Cutting | Cuts panels to the right length and saves material. |

Continuous Production

You want to finish big jobs quickly. Continuous production helps you do that. The machine works without stopping. You get lots of panels at speeds of 30-40 meters per minute. You save money because you need fewer workers. Automation keeps everything running smoothly. You get good sheets with the same thickness and shape every time.

Make lots of panels fast

Spend less money because the process is efficient

Get good sheets with the same thickness and shape

Need fewer workers because of automation

Machine works most of the time and needs little fixing

Can make custom orders easily

Get more panels and waste less material

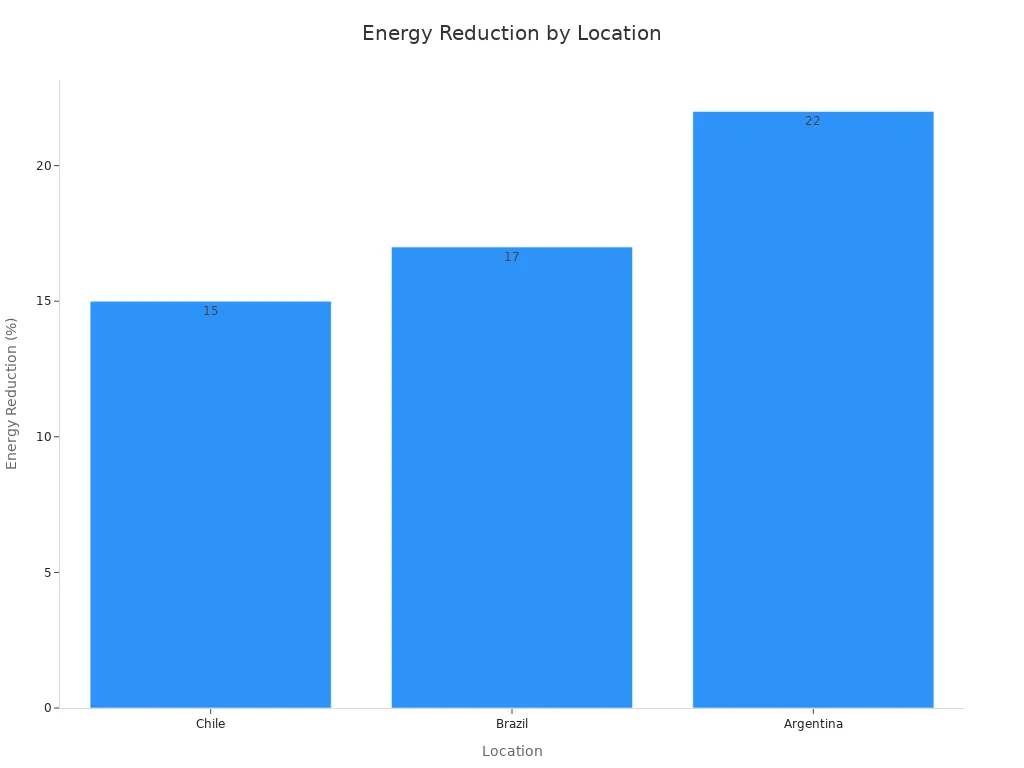

You also help the environment. New machines use less energy than old ones. Smart sensors and speed controls lower energy use by up to 22%. Here is a chart showing energy savings in different countries:

A High Speed Roof Panel Roll Forming Machine gives you even more benefits. You spend less on electricity. You waste less material. You make more panels with less work. You keep costs low and customers happy.

Note: Automation also helps when you have fewer workers or not enough raw materials. Your business keeps running well.

Types of Roofing Sheet Manufacturing Machines

You have lots of machines to pick from for roofing sheets. Each machine has its own good points. Let’s see the main types and find what you need.

High Speed Roof Panel Roll Forming Machine

This machine helps you finish big jobs fast. It works quickly and uses flying cutting systems. The line does not stop during work. You can make many panels for big orders. The panels are smooth and the size is always right. You save time and money because you need fewer workers. This machine is best for big factories with lots of work.

If you want to be the best, pick a High Speed Roof Panel Roll Forming Machine. You will make more panels and keep your customers happy.

Standard Roll Forming Machine

You might not need the fastest machine for every job. A standard roll forming machine works at a normal speed. It shapes metal sheets into roofing panels. You get good quality and steady results. This machine is good for small or medium businesses. It is great for regular roofing jobs where speed is not so important.

Tile Profile Roll Forming Machine

You want roofs that look nice and last long. The tile profile roll forming machine makes panels that look like tiles. You get strong and pretty panels. This machine is good for homes, offices, and shops. You can give your customers more styles to pick from.

Specialized Machines

Some jobs need special machines. You can pick machines like standing seam, corrugated, or sandwich panel roll forming machines. Each one does something different. For example, a standing seam machine makes panels that are easy to move and put in place. A corrugated machine makes sheets fast and does not make much noise. A sandwich panel machine makes insulated panels for buildings that save energy.

Here’s a quick look at common machines and what they do:

Machine Type | Use Case Description |

High Speed Roof Panel Roll Forming Machine | Makes lots of panels fast for big jobs, uses flying cutting. |

Standing Seam Metal Roof Roll Forming Machine | Makes custom steel sheets, easy to move, good for special roofs. |

Corrugated Roof Sheet Roll Forming Machine | Makes sheets fast and quiet for many roof types. |

Sandwich Panel Roll Forming Machine | Makes insulated panels for buildings that save energy. |

Glazed Roof Tile Roll Forming Machine | Makes stylish tiles for homes and offices. |

Metal Roof Roll Forming Machine | Makes metal roofing for all kinds of projects. |

You can see the High Speed Roof Panel Roll Forming Machine is special. It gives you speed, good size, and nonstop work. You make more panels in less time and spend less money.

Key Features and Benefits

Speed and Efficiency

You want to finish roofing jobs fast. The High Speed Roof Panel Roll Forming Machine helps you do this. This machine is much quicker than regular ones. Look at the table below to see the speed difference:

Machine Type | Speed Range (meters per minute) |

Standard Roll Forming Machines | 9 to 45 meters per minute |

High-Speed Roll Forming Machines | Up to 90 meters per minute |

You make more panels in less time. The flying cutting system keeps everything moving. You do not stop the line to cut. This saves time and helps you make more panels. The machine cuts each sheet while it moves. You avoid waiting and your team works better.

Tip: Fast machines help you get big jobs and keep customers happy.

Profile Versatility

You want to make many roof styles. Modern machines shape steel, aluminum, and more. You can make panels for homes, factories, and offices. The table below shows what metals you can use:

Material Type | Thickness Range |

Galvanized Steel | 0.4-0.7 mm |

Color Steel | 0.4-0.7 mm |

Aluminum-Magnesium-Manganese Plate | 0.4-0.7 mm |

Coil Sheet | 0.3-0.6 mm |

You can change profiles and thicknesses. This helps you meet different needs. You get more work and your business grows.

Quality and Consistency

You want every panel to look great. The flying cutting system gives clean, sharp edges. You get sheets that are always the right size. The machine is quiet and safe to use. You avoid rough cuts and do not waste metal. You also get automatic sizing and different cutting modes. Your panels stay strong and look nice.

Precise cutting keeps panels the same size.

Synchronous cutting means no stopping.

Safety features keep your team safe.

Low noise makes your shop nicer.

BMS Roll Forming Machinery Advantages

You want a machine that lasts a long time. BMS roll forming machinery has strong parts and is easy to care for. Regular checks keep your machine working well. Scheduled care stops problems before they start. Your rollers and cutters last longer.

Machine Type | Warranty Duration | After-Sales Support Details |

Decoration Panel Roll Forming Machine | 1 year | Free replacement parts during warranty; lifetime help; training and setup included. |

Metal Architectural Louver Roll Forming Machine | 2 years | Free replacement parts during warranty; lifetime help; training and setup included. |

You get great help after you buy. BMS gives free parts during the warranty and help for life. Customers give BMS a perfect score. You join many happy buyers who trust these machines.

Note: Pick BMS for strong machines, good help, and happy customers.

Applications in Roofing

Residential Projects

You want your house to have a strong roof. Roofing sheet manufacturing machines make panels that last long. You can pick from many styles and colors. These machines make panels that fit your home well. The panels protect you from rain, wind, and heat. You save money because the panels need little care. Many people choose metal roofing because it is light and tough. You can trust these machines to give you a safe roof.

Commercial and Industrial Use

Big buildings need roofs fast. A High Speed Roof Panel Roll Forming Machine helps you finish jobs quickly. You control how many panels you make. On-site roll forming lets you cut panels to the right size. You waste less material and save money. You do not pay extra for other suppliers. You get panels when you need them. This keeps your team busy and your project moving. You also avoid damage from shipping and mistakes during setup. Here are some ways these machines help:

Cut panels to the right size and waste less

Avoid extra costs from other suppliers

Make panels fast and keep workers busy

Fix mistakes quickly and make changes fast

Save money by buying only metal coil

Keep downtime low and finish jobs faster

Meet customer needs with different panel styles

More companies use these machines for strong and light roofs. They want roofs that save energy and help the environment. New technology makes the process better. Government rules support green materials. Cities are growing, so more people need these machines.

Custom Roofing Solutions

You want your building to look special. Roofing sheet manufacturing machines let you make custom panels. You can change the roll forming stations and use different dies. This helps you match any building style. The table below shows how you can change your panels:

Customization Feature | Description |

Adjustable Roll Forming Stations | Change the process to make different roofing profiles |

Interchangeable Dies | Use new die shapes for special architectural designs |

You can give customers more choices. You meet special requests and make buildings look unique. These machines help your business grow and keep clients happy.

You want your roofing projects to turn out great. High Speed Roof Panel Roll Forming Machines work fast and make custom panels. They help you waste less material. Special features like flying cutting and nonstop work save time and money. BMS roll forming machinery is easy to use and gives strong support.

Key Considerations | Why They Matter |

Fast, precise output | Finish big jobs quickly |

User-friendly controls | Make work simple and safe |

Reliable support | Keep your business running well |

Pick BMS to help your business grow. Contact them today to find out more or get a price.

FAQ

What materials can you use in a roofing sheet manufacturing machine?

You can use galvanized steel, color steel, and aluminum. These machines work with different thicknesses. You get panels that are strong and last in bad weather.

How do you maintain a roll forming machine?

You need to clean the rollers often. Check the oil and look at moving parts. Taking care of your machine helps it work well and saves money on repairs.

Can you make custom roofing profiles?

Yes! You can change the machine to make many shapes and sizes. This helps you give special designs and meet what customers want.

Why should you choose BMS roll forming machinery?

The machines are reliable.

You get good help after you buy.

The machines are easy to use and work fast.

You can grow your business with new features.