Specification of

Highway W Beam Roll Forming Machine

Profile:

Type 1

Type 2

Material

Effective Width:312/502/506mm

Material Thickness:2.5-3.81mm

Applicable Material: Galvanized Steel, Hot Rolled Steel Coil

With Yield Strength 345-550Mpa

Inspection Thickness:2.67/3.42/3.43mm

Work Follow

6 Ton Hydraulic Decoiler →Leveling Device → Hydraulic Punching Device→ Feeding Device→Main Machine System→Hydraulic Post Cutting →Exit Rack

Punching Holes:(as follows)

Type 1:19x64 & 23x29;Type 2:19x64 & 23x29

Total need 2 punching molds

Machine Components

1) 6 Ton Hydraulic Decoiler:one set

2) Feeding and Leveling Device

With feeding material guide and leveling device

Up Three down Four totally seven shafts leveling device

body frame made from H450 type steel by welding;Side wall thickness: Q235 t30mm Shafts manufactured from 45# steel,Diameter=φ120mm,Tone plated with hard chrome Coated,precision machined

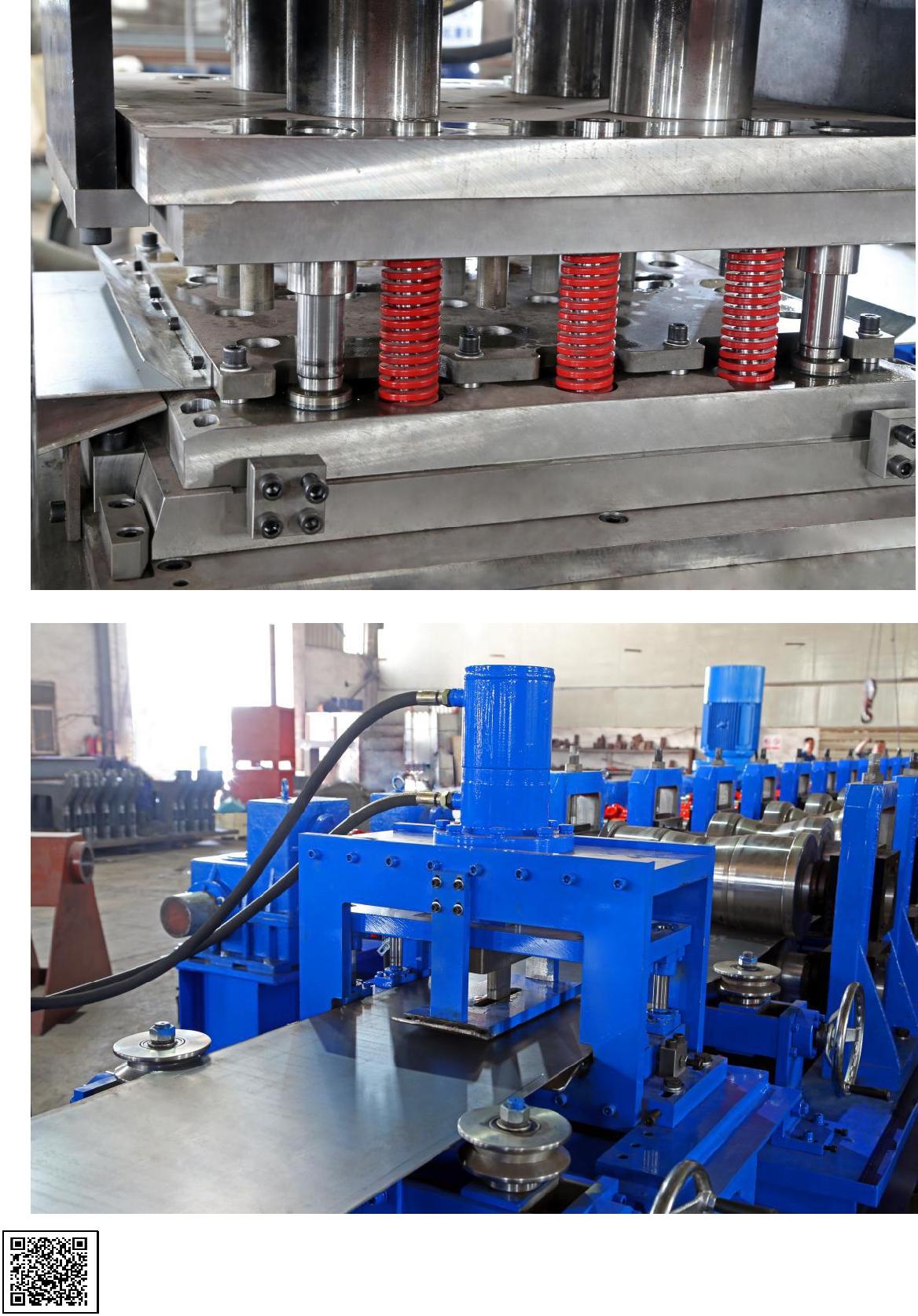

3) Punching Hole Device(With Four Punching Hole Molds)

Hydraulic motor:37KW, Hydraulic pressure range:0-25Mpa(250bar)

Punching and Cutting tool material:mold steel Cr12MoV(=D2 steel, with one million times punching/cutting life), Heat treatment to HRC58-62 degree

2-cylinders hole punching system ,total need four punching molds19x64 & 23x29 & 20x65 & 24x30

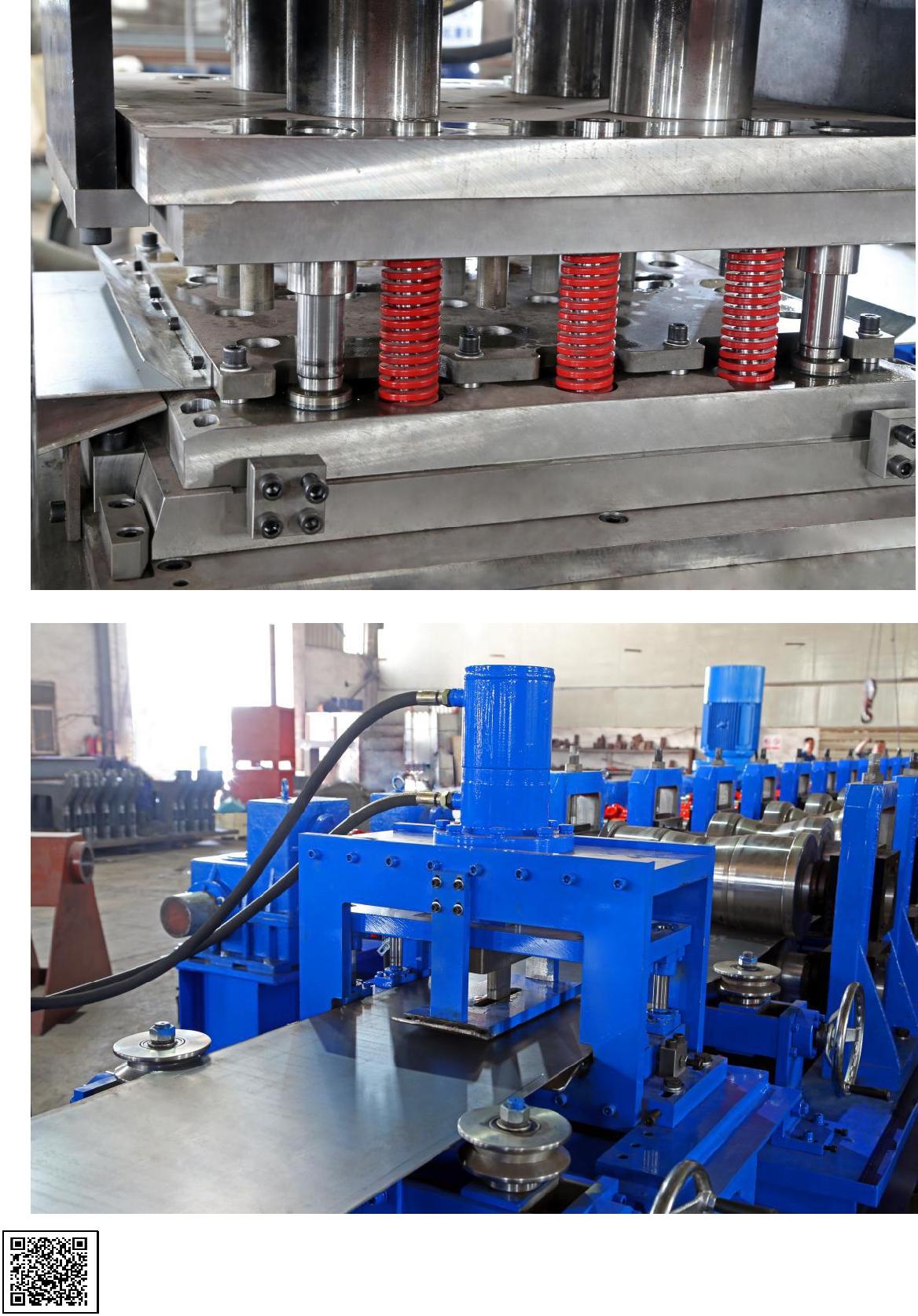

4) Main Machine

Body frame made from H450 type steel by welding

Rollers manufactured from Cr12 Steel,CNC lathes,Heat Treatment Shafts Diameter=ф95,precision machined

Gear Box drive (upper and lower rollers with power)

Column type structure design(Cast iron memorial arch,thickness:55mm) Gear Box driving,about 19-step to form

Main Motor=45KW,Frequency speed control Speed redcucer motor:K series

Sliding block:150*150mm

All the screw bolts with grade 8.8(cheap factories use low grade 4.8) to ensure fix the machine structure tightly and long life during the machine long time running

Real forming speed 12-16m/min

With Water Cold Device(For Better Product)

19 Gear Boxs Drive,38 Transmission Shafts (Up And Down The Shaft)

Column type structure design(Cast iron memorial arch,thickness:55mm)

5) Post Hydraulic Cutting Device(Total need Two Cutter molds)

Post to cut, stop to cutting,Three pieces type of cutting blade design, no blanking Hydraulic motor:37KW,with Punching Device Share a hydraulic station

Cutting pressure: 0-25Mpa(250bar);Cutting tool material: Cr12MoV(= SKD11 with at least one million times of cutting life), Heat treatment to HRC58-62 degree

The cutting power is provided by the Independent hydraulic station

The hydraulic system with oil filter for the oil filtration,to ensure the circulated oil is clean and lengthen the life of hydraulic system.(See the picture below)

\

6) PLC Control System

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen , It Can Finish The Production Automatically.

Combined With: Inverter, Encoder, etc

Cut-to-Length Tolerance≤±1mm

Control Voltage 24V

7) Exit Rack: Un-powered, One unit,with rollers on it for easy movement

8) Finished Product