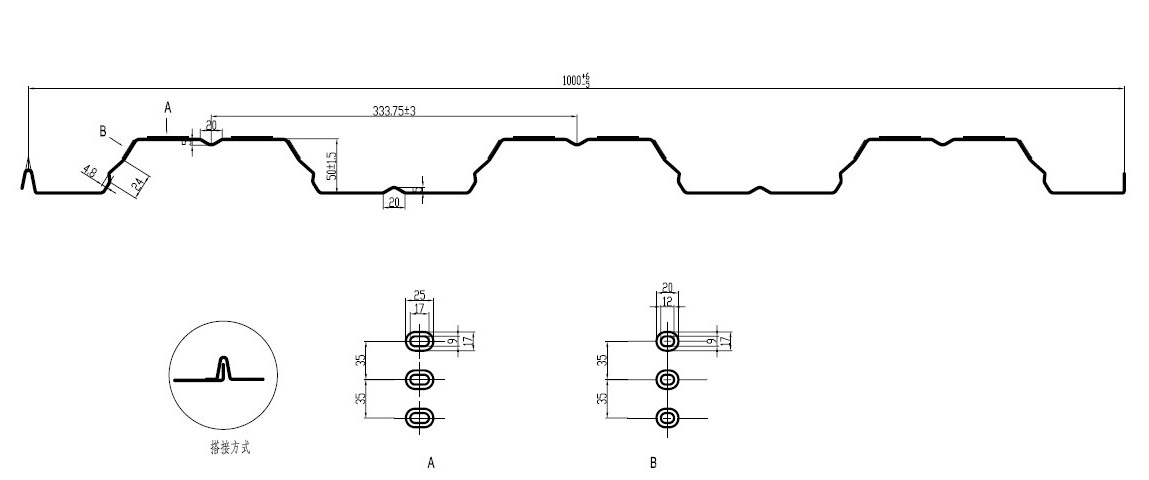

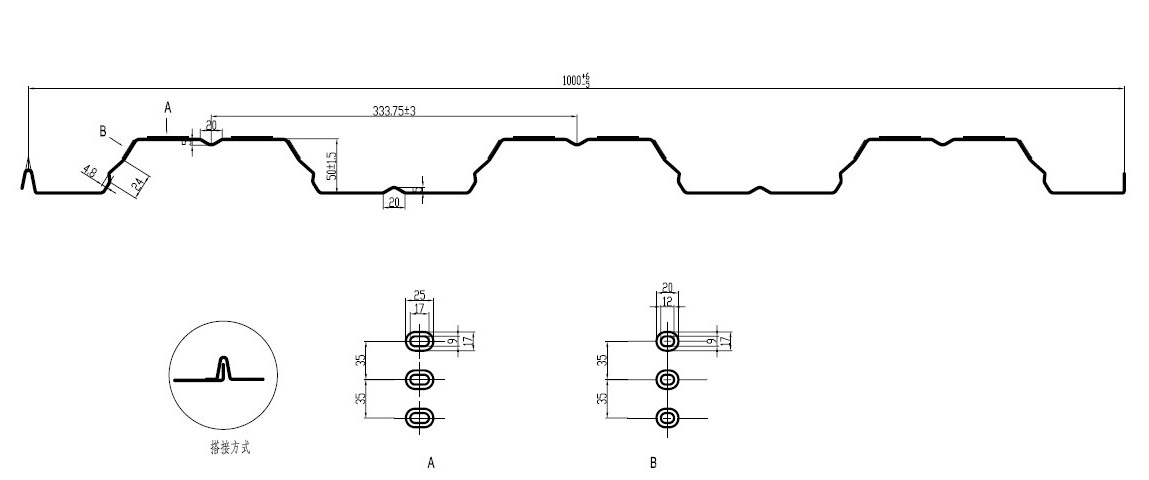

Floor Decking Roll Forming Machine for YX50-333-1000 profile

ⅠProfile Drawing

Effective width tolerance:-0/+5mm

Other section tolerance:+/-0.5mm

Ⅱ. Material:

Feeding Material Width: 1220mm & 1250mm

Material Thickness: 0.7-1.5mm

Applicable material: Galvanized Sheet, 250Mpa Yield Strength for 0.7-1.5mm thickness, 500Mpa yield strength for 1.2mm thickness

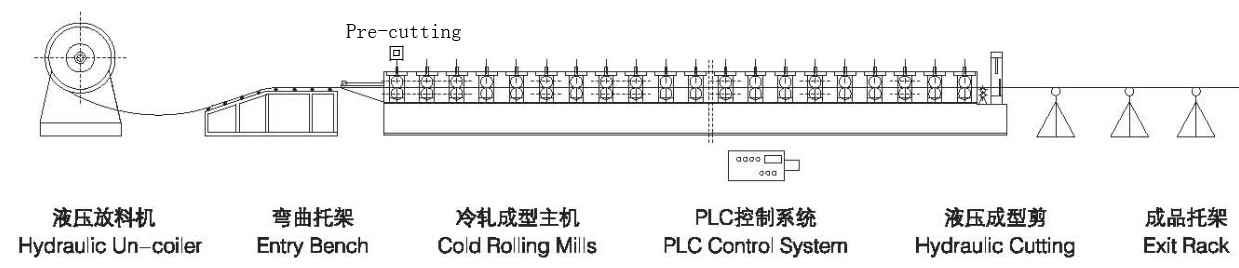

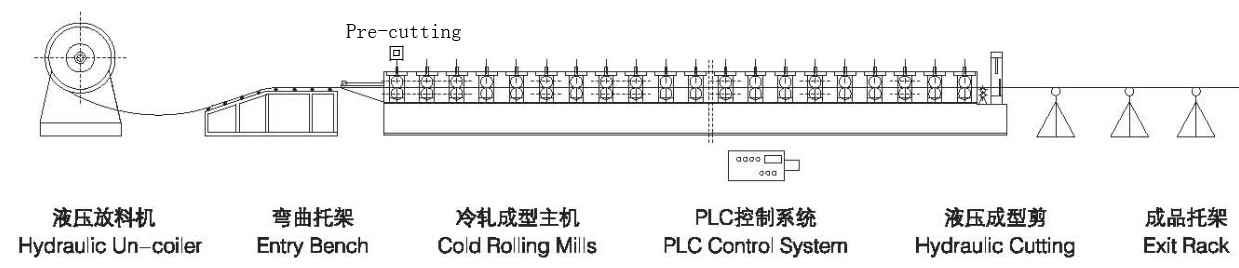

Ⅲ.Flow Diagram:

Decoiler →Feeding Device →Main Forming Machine → Hydraulic Post Cutter→Exit Rack.

Ⅳ.Machine Components:

1) Hydraulic Decoiler: one set 5-7tons

2.Main Roll Forming Mill

With feeding material guide,

Roll forming machine combined with body frame, transmission mechanism and forming rollers, etc.

a) Body frame made from H450 type steel by welding with beautiful appearance, natural aging treatment and SR(stress relief) treatment.

b)The body frame is wall board type: shaft diameter φ95/90mm,made from 45# steel, heat treatment. The lower shaft is main transmission by gear chain.

c)Rollers manufactured from No. 45 high quality steel, heat treatment

d)Transmission by motor driving, gear chain transmission, about 24-step to form

Main Motor=15KWx2, Frequency speed control

Forming speed approx.16m/min

e) The material for Embossing roller: bearing steel GCr15(=EN31) for long working life, heat treatment

f) All the screw bolts with grade 8.8 to ensure fix the machine structure tightly and long life during the machine long time running.

3) Hydraulic Cutting device:

Post cut, stop to cutting, three pieces of blade to cutting

Pre-cutting and post cutting,use the same hydraulic system

Pump motor: 5.5KW Cutting pressure: Max.16Mpa

Cutting tool material: mold steel Cr12Mov(=D2 steel, with at least one million times of cutting life), Heat treatment

With 2 Guide Pillar for shearing support,which make the shearing more stable and lenger life for cutter.

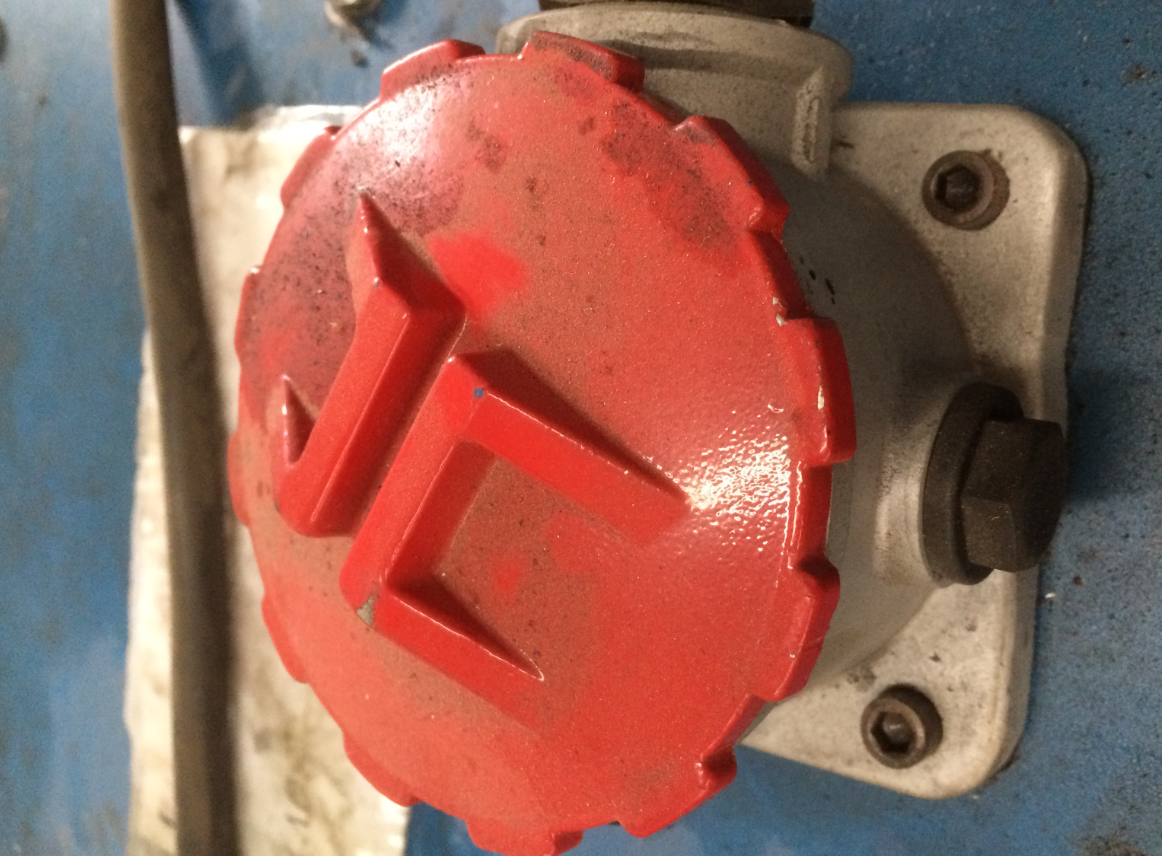

The hydraulic system: Huade(China TOP1 brand)/Yuciyouyan(Joint venture with Japan Yuken), with oil filter for the oil filtration,to ensure the circulated oil is clean and lengthen the life of hydraulic system .(See the picture below)

4)PLC control system

Description: Computer control system, controlled by PLC. The encoder control the width and height of the sheet automatically, and control the length positioning and cutting, 7inch touch screen operation, the precision is controlled within ±1.0mm

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

5) Exit rack:

Un-powered,3mx2units with rollers for easy movement

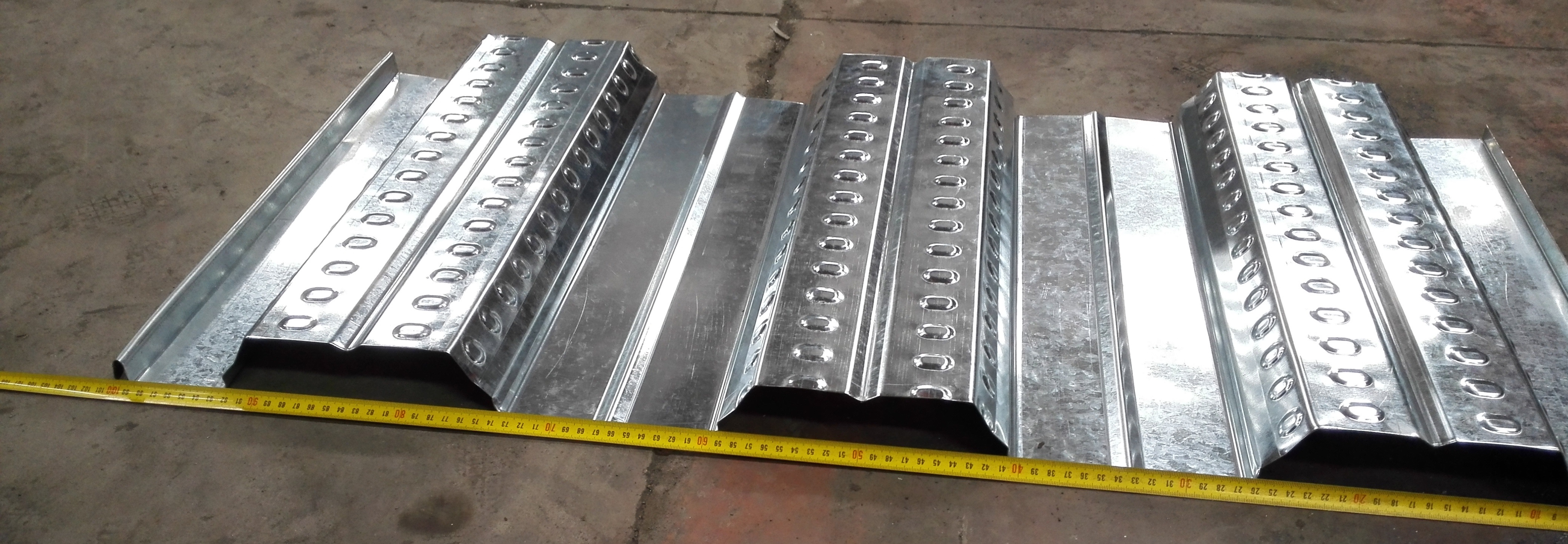

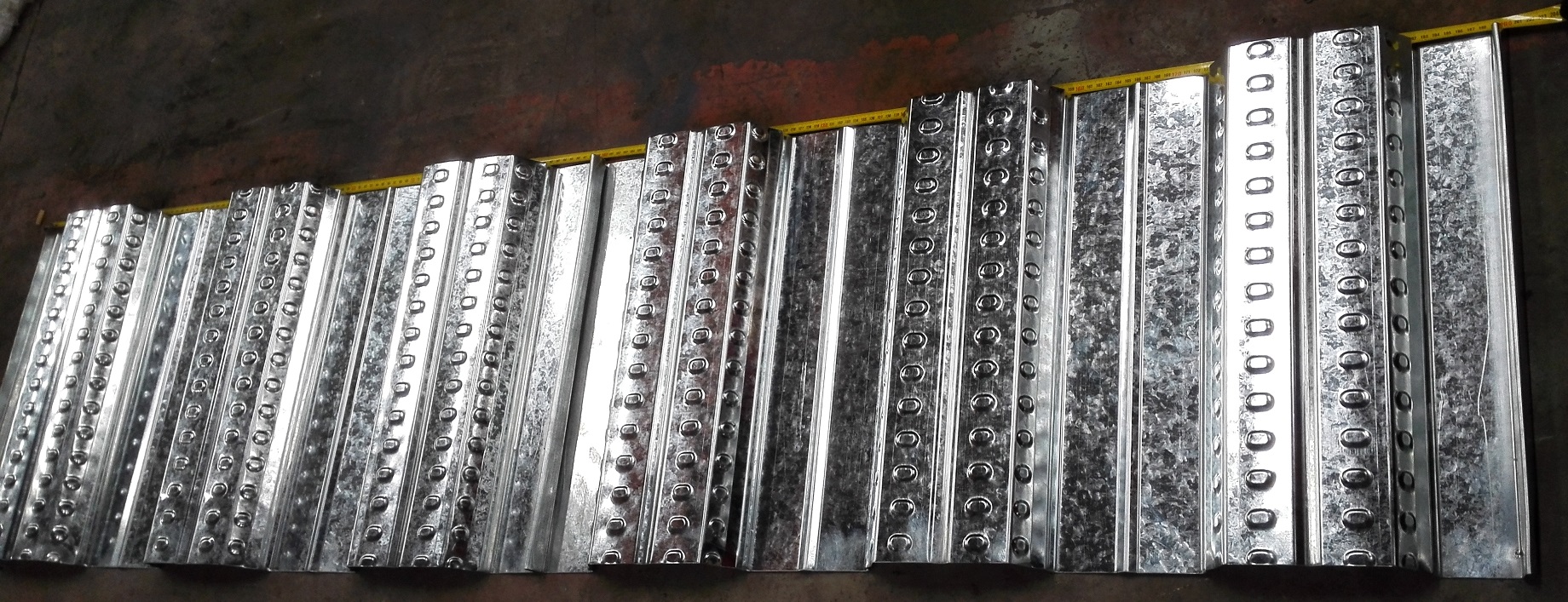

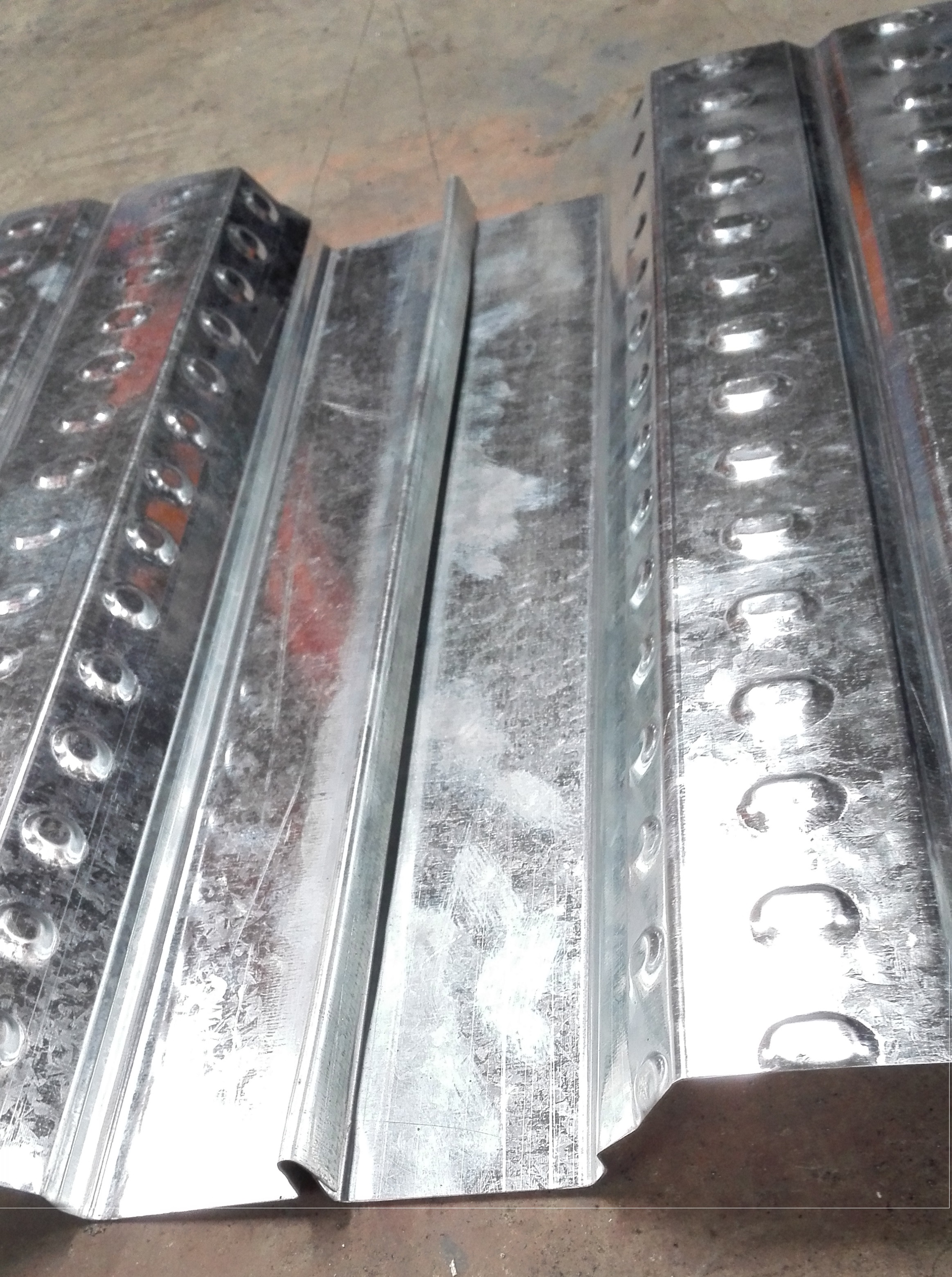

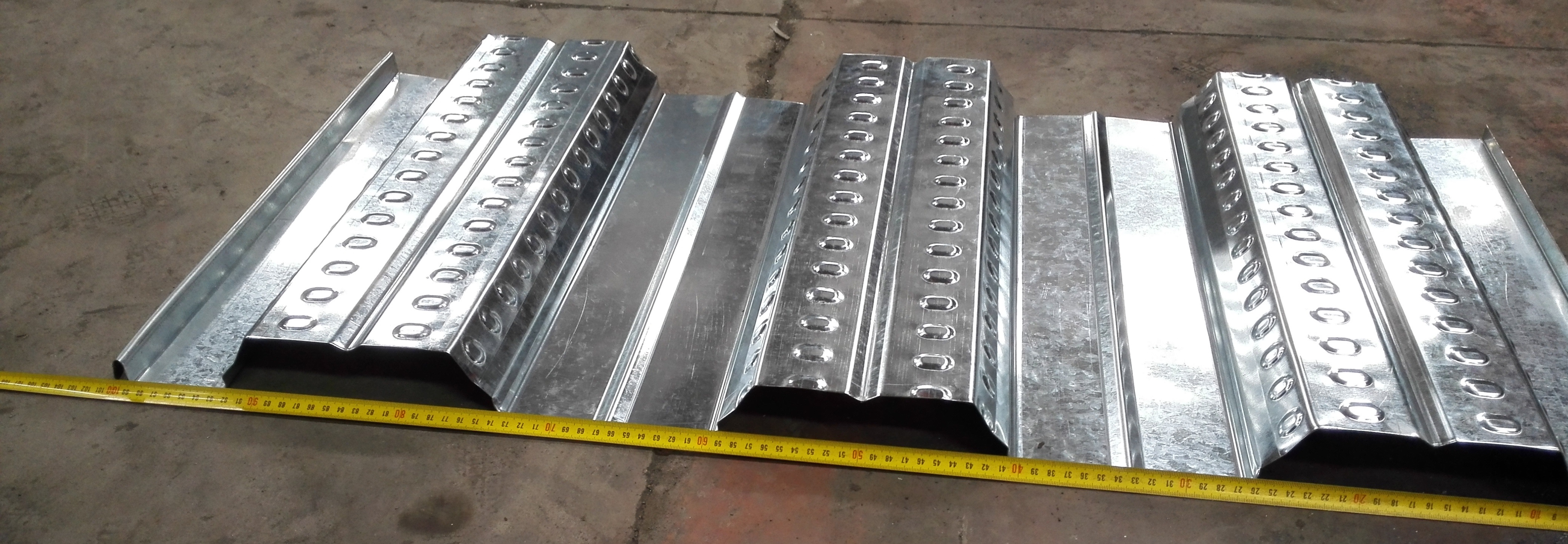

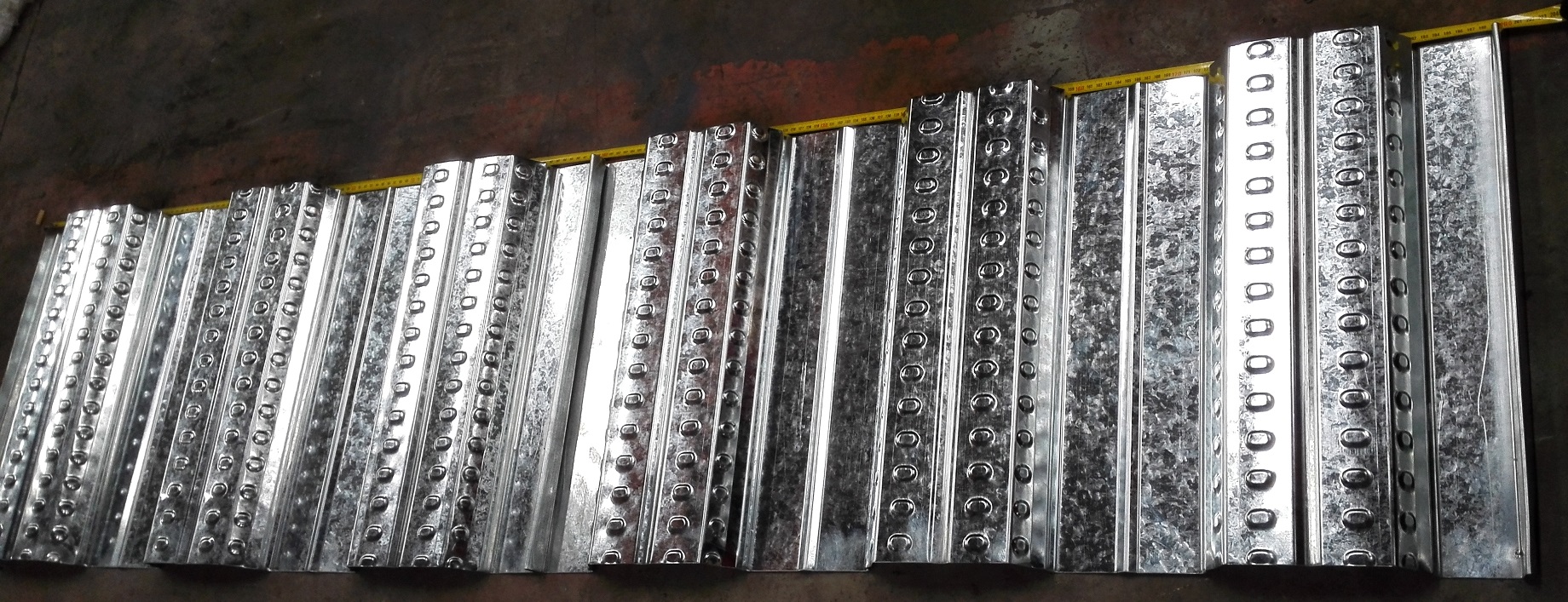

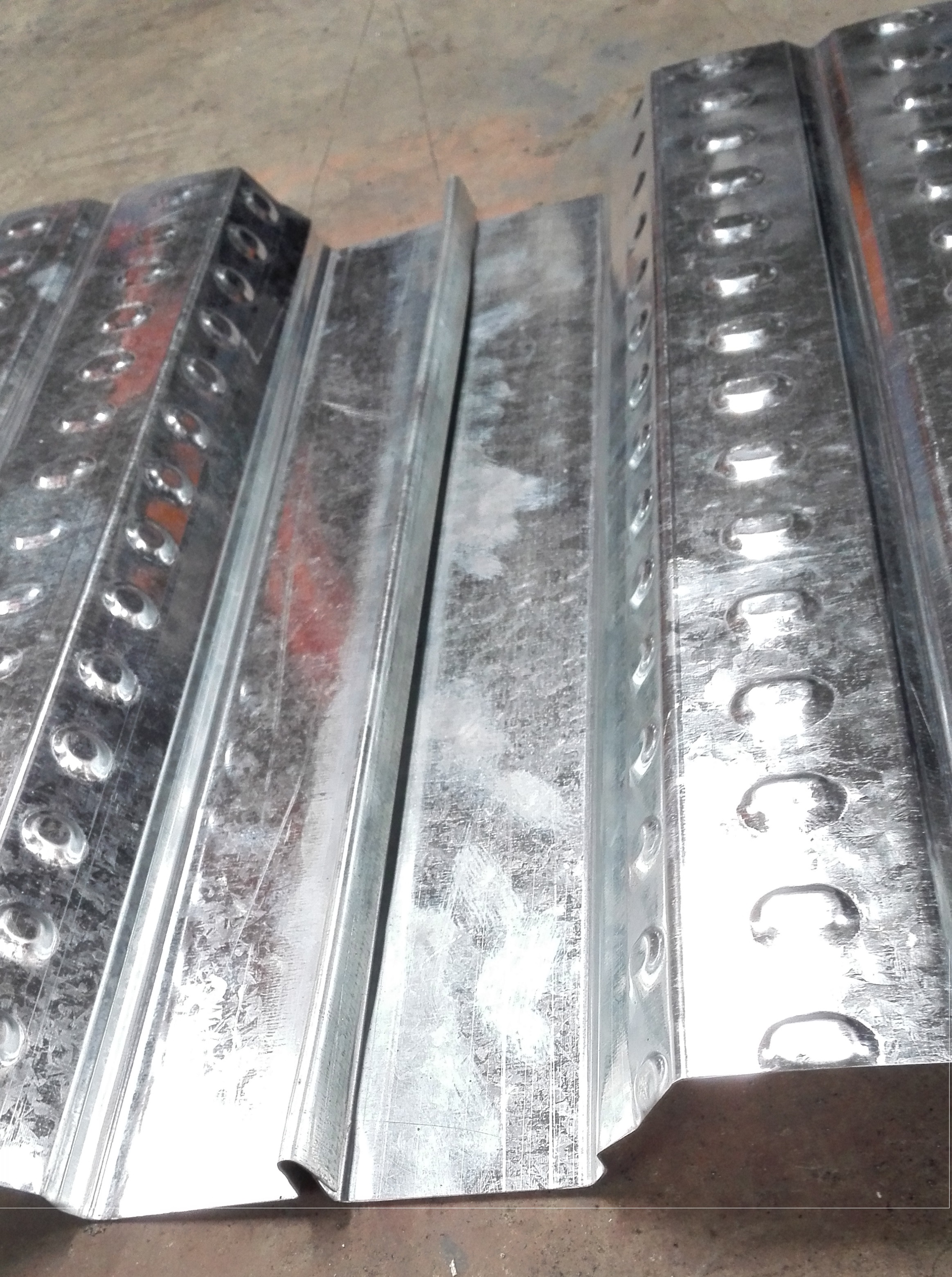

Ⅴ.Machine Picture(just for reference)

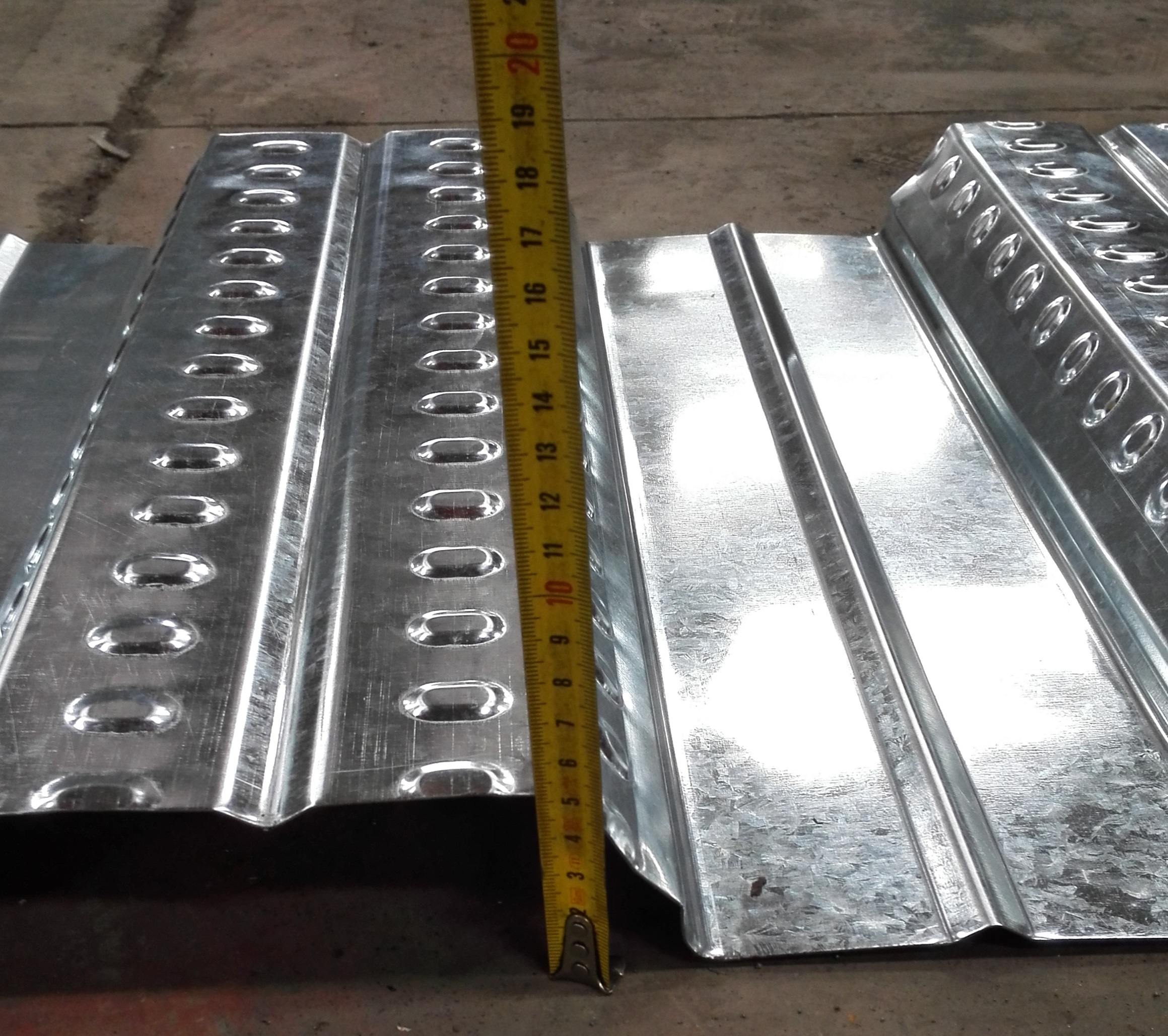

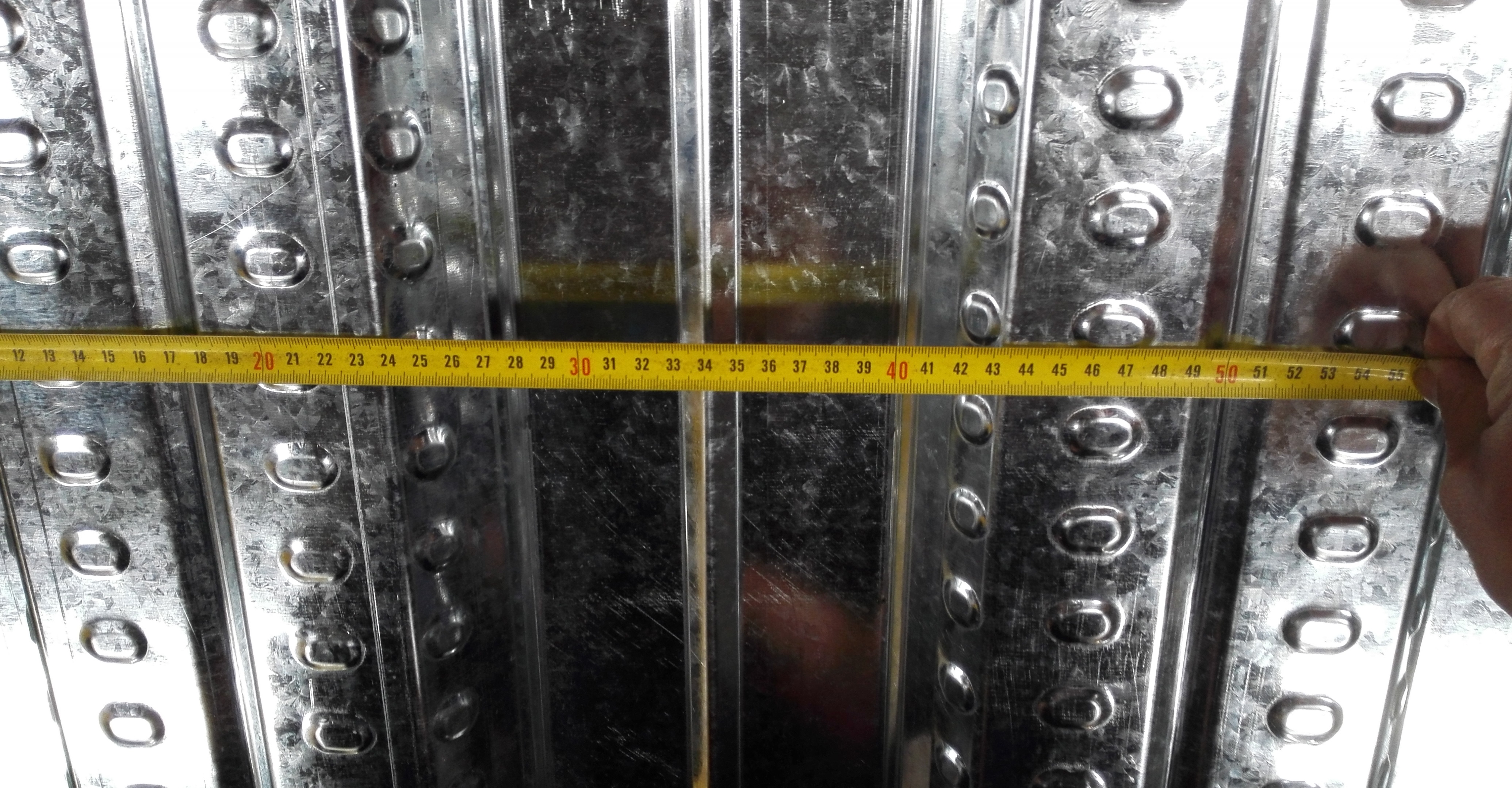

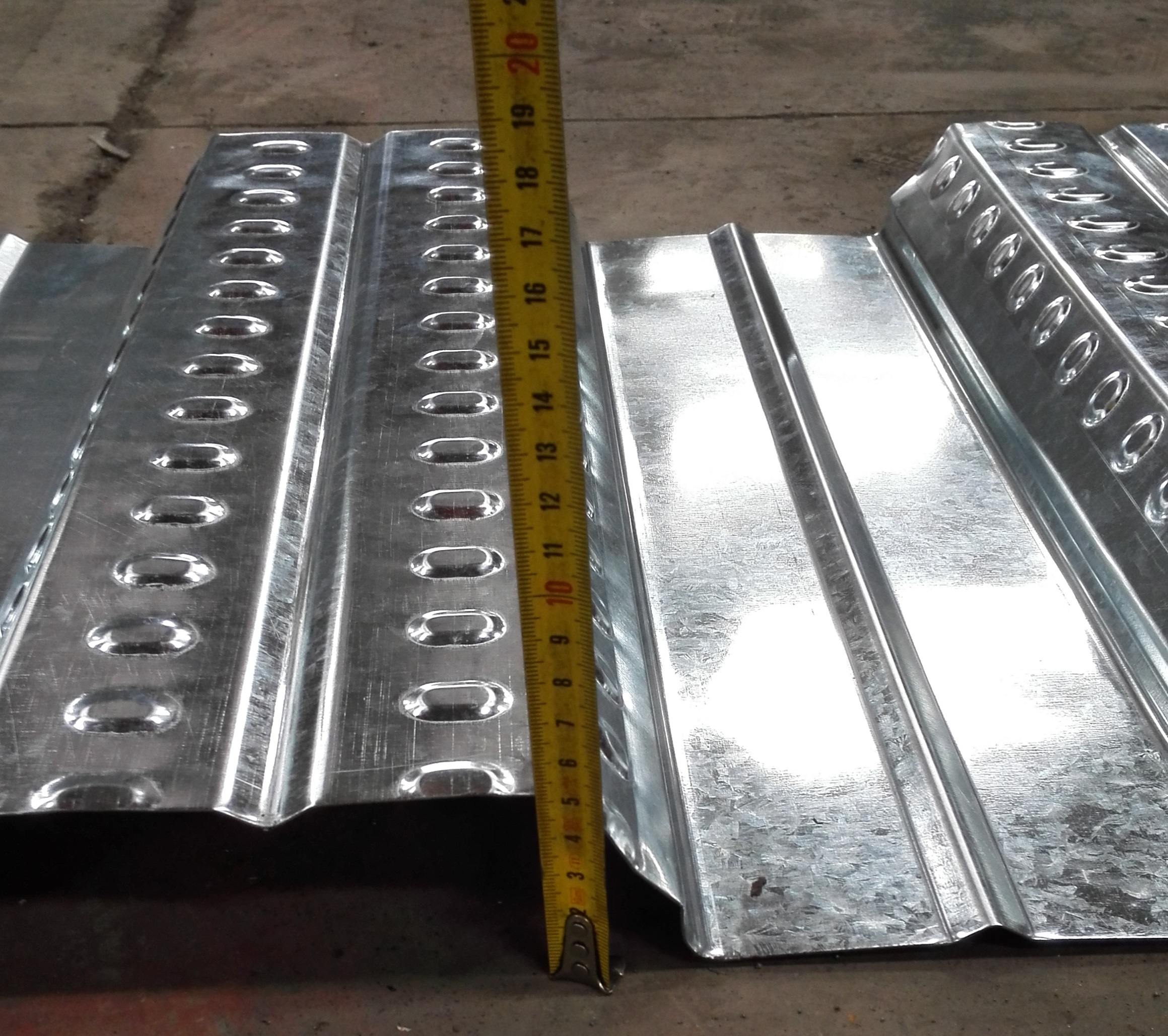

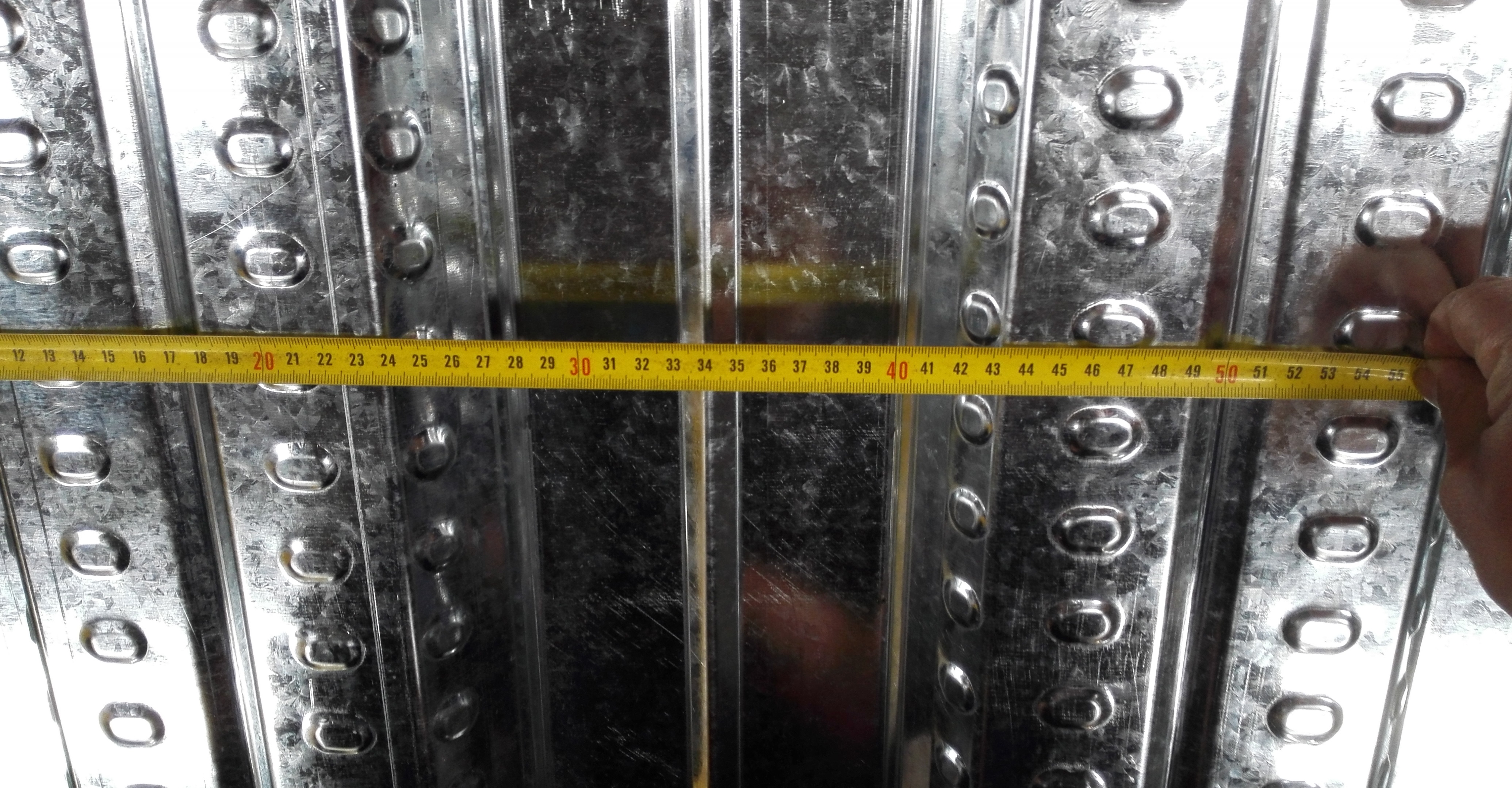

VI. Machine produced floor deck inspection:

Overlap of 2 profiles:

Overlap joint effect:

Machine total weight: about 15Tons

Machine dimension: about 12.5m(length) X 1.8m(width) X 1.5m(height)

Floor Decking Roll Forming Machine Video link:

https://www.rollformingmachinerychina.com/european-style-floor-decking-machine_n87

Above specifications and photos are only for reference, the accurate one maybe slightly differ and need to refer to the machine.