Specification of

Corrugated Roof Roll Forming Machine

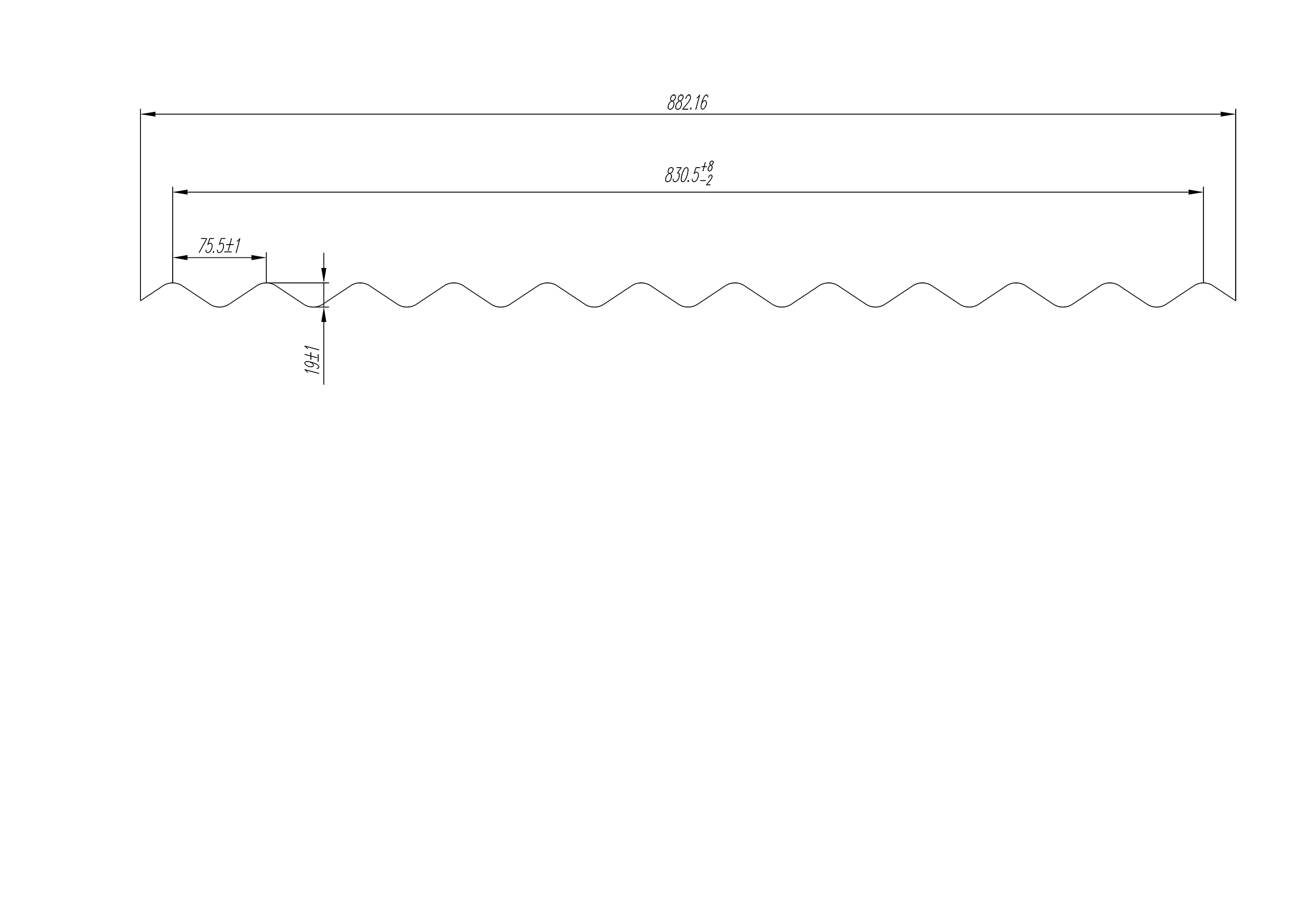

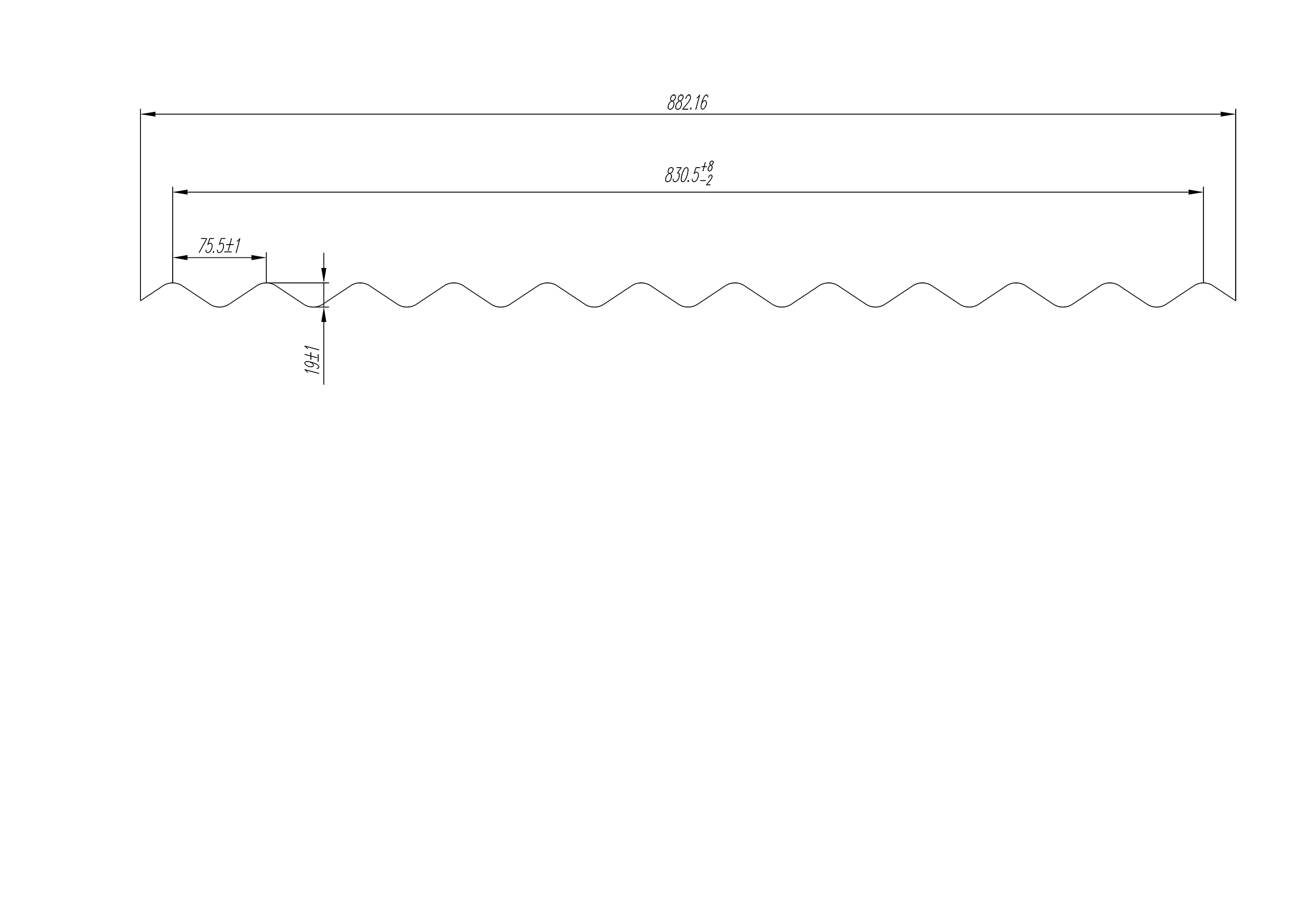

For YX19-75.5-830.5 Profile

Corrugated Roof Roll Forming MachineYX19-75.5-830.5 Quotation

Profile

Material

Effective width: 830.5mm Effective width tolerance:-2/+2mm

Feeding width: about 1000mm The Wave spacing tolerance:±0.5mm

Material Thickness: 0.3-0.6mm The wave height tolerance:±0.5mm

Applicable material:PPGI and GI The length of tolerance:±1(6m)

Cold roll steel(CRC)with yield strength 245-350Mpa Inspection thickness:0.4mm

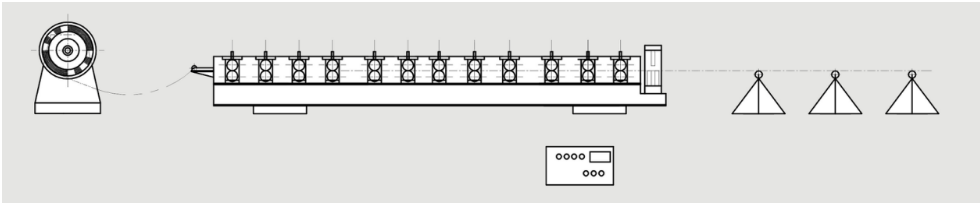

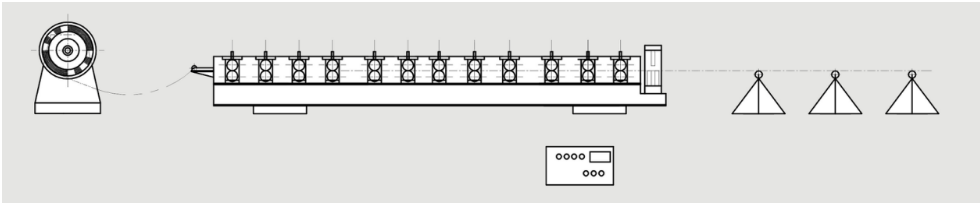

Work follow

Decoiler→Manual Pre-Cutter→Guide Feeding →Roll Forming System→Hydraulic

Post Cutter →Exit Rack

Machine Components

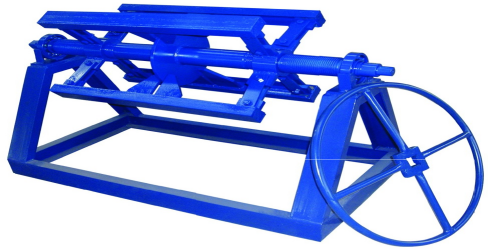

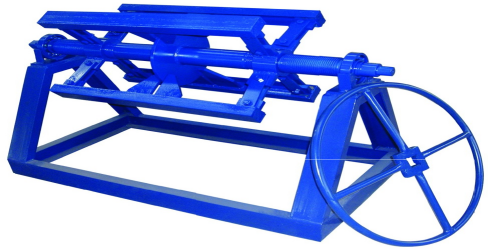

1) Manual Decoiler: one set

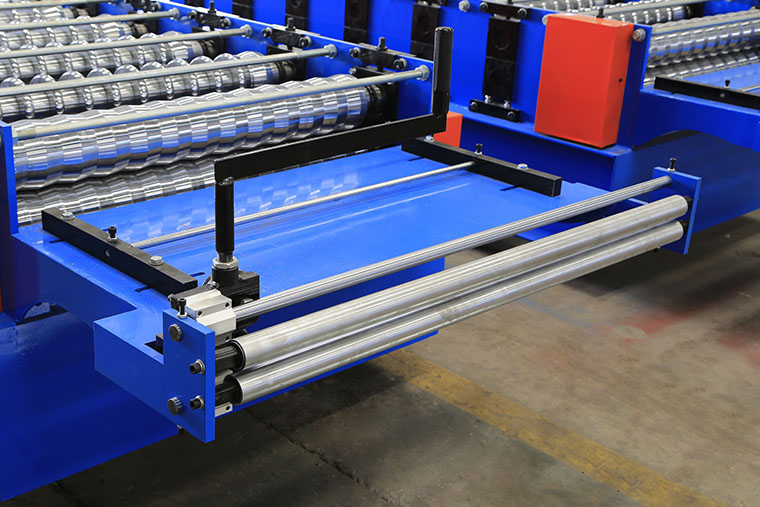

1) Pre-Cutter

With manual pre-cutter for easy operation and save material:

It is the advanced function and good for production to save material, no waste

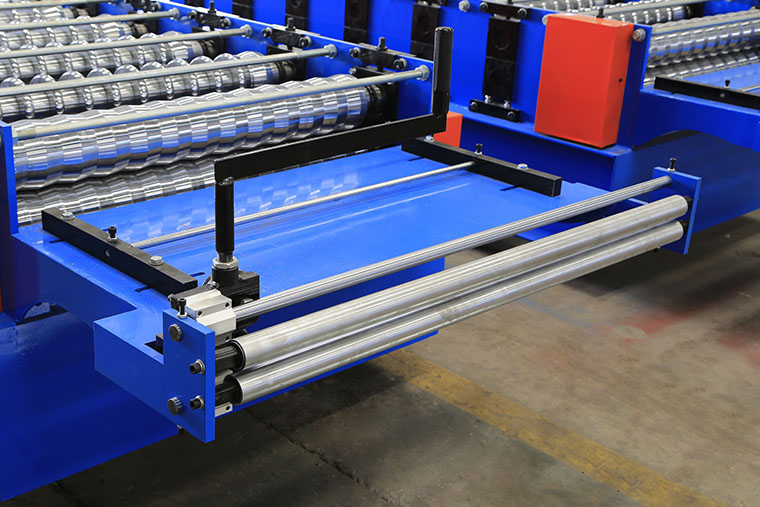

3) Main Machine

With feeding material guide, body frame made from H450 type steel by welding

Side wall thickness: Q235 T18mm ;Tie rod:ф22 Galvanized

Rollers manufactured from 45# steel,CNC lathes,Heat Treatment,hard Chrome Coated

with thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust)

The warranty for the rollers is 5 years

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving,about 18-step to form

Main Motor(Polaroid brand)=7.5KW , Frequency speed control

Speed redcucer motor:R series;

Chain: ZIQIANG (by China TOP 1 brand DONGHUA Group)

Chain size: one inch with 18teeth

Sliding block:130*140mm;

All the screw bolts with grade 8.8 to ensure fix the machine structure tightly and long life during the machine long time running.

Real forming speed for material thickness 0.35mm:18-22m/min (Not include cutting time)

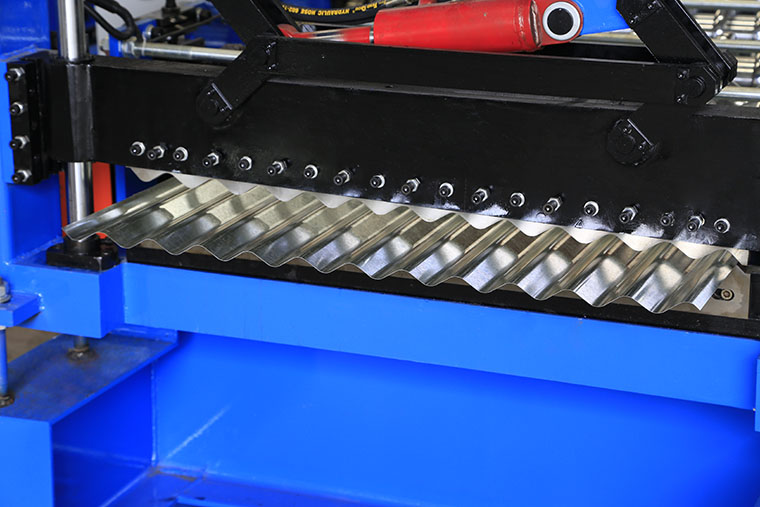

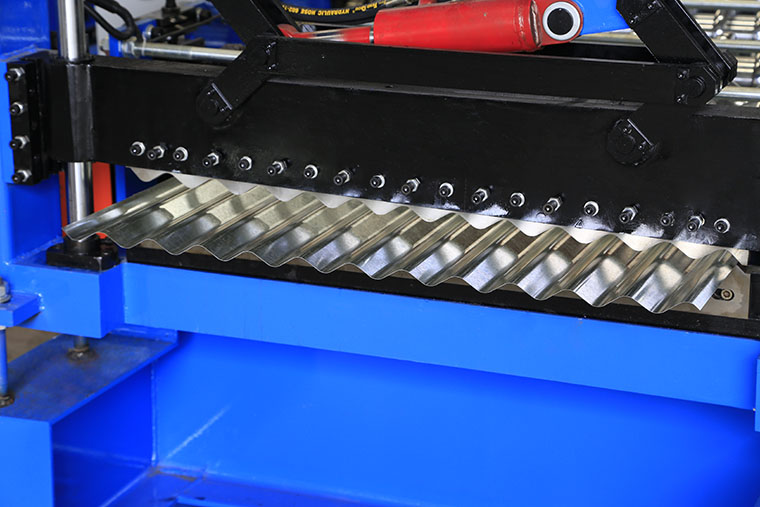

4) Post Hydraulic Cutting Device

Post to cut, stop to cutting,Two pieces type of cutting blade design, no blanking

Hydraulic motor: 4KW ;Cutting pressure: 0-16Mpa;Cutting time:2s

Cutting tool material: Cr12Mov(= SKD11 with at least one million times of cutting life), Heat treatment to HRC58-62 degree

With 2 Guide Pillar for shearing support,which make the shearing more stable and longer life for cutter

The cutting power is provided by the main engine hydraulic station

The hydraulic system with oil filter for the oil filtration,to ensure the circulated oil is clean and lengthen the life of hydraulic system .(See the picture below)

5) PLC Control System

Control The Quantity And Cutting Length Automatically

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen ,

It Can Finish The Production Automatically.

Combined With: PLC, Inverter, Touch Screen, Encoder, etc

Cut-to-Length Tolerance≤±1 mm

Control Voltage 24V

6)Exit Rack: Un-powered, Two units,with rollers on it for easy movement

Above specifications and photos are only for reference, the accurate one maybe slightly differ

and need to refer to the machine.