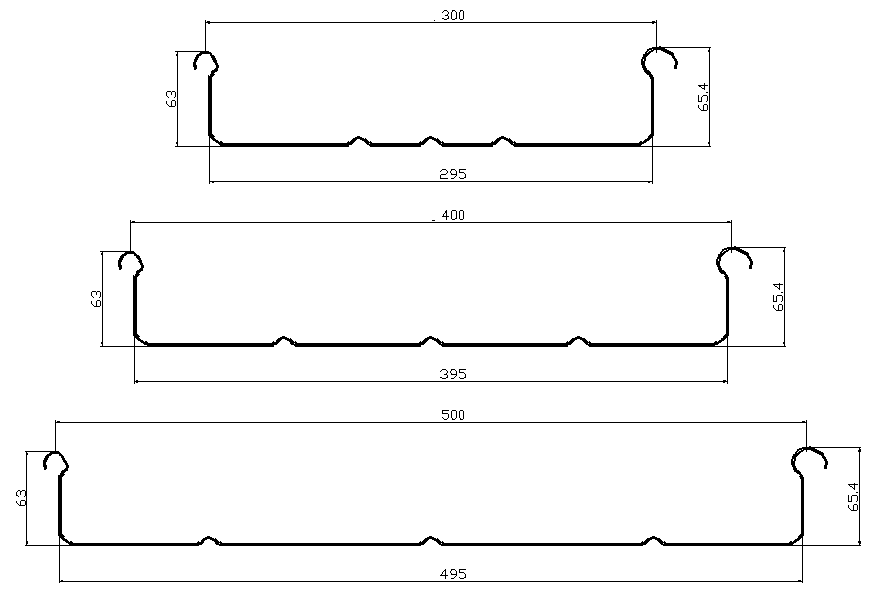

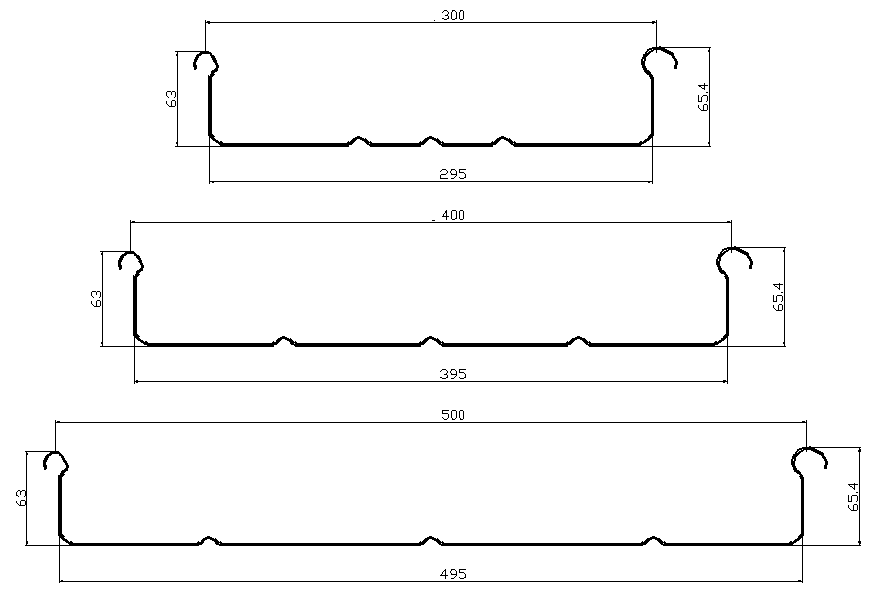

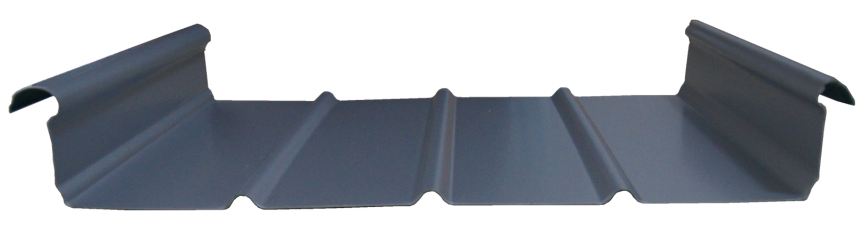

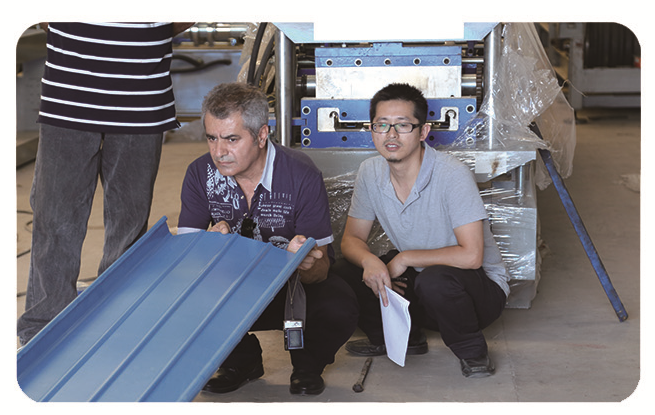

I. Standing Seam Profile YX65-300,400,500 Cold Roll Forming Machine

YX65-400(adjustable)Rollforming machine can form 3 type sheets (effective width 300mm,400mm,500mm)

Profile:

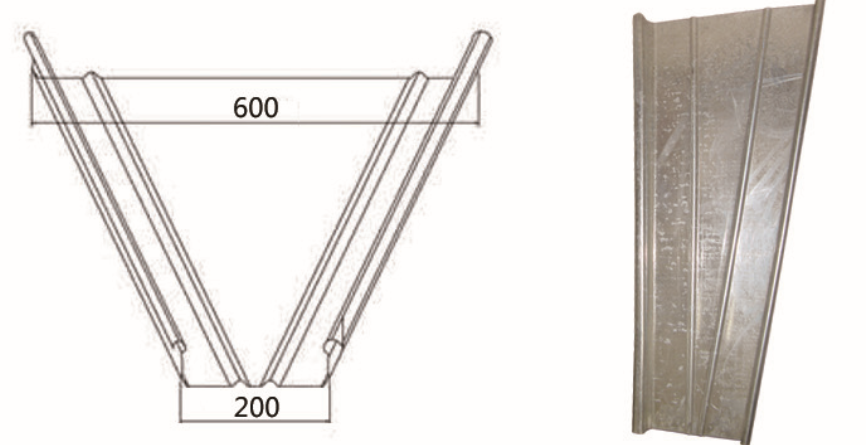

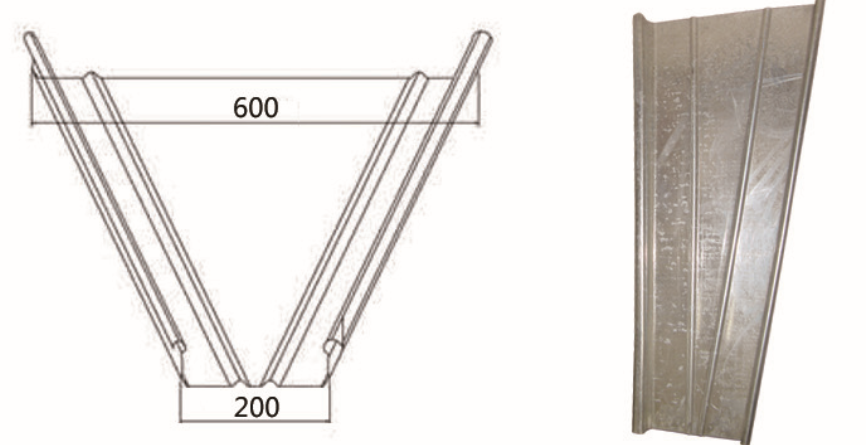

Taper:

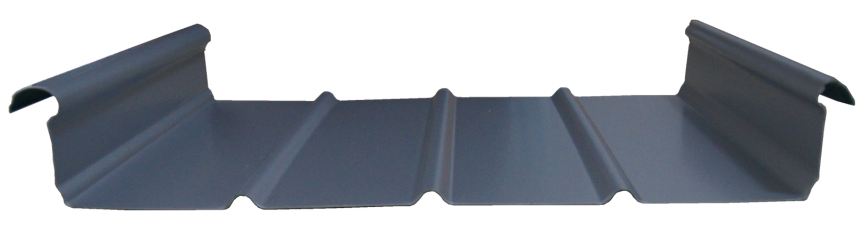

Sample panel:

----as reference

Material: Aluminum: 0.7-1.2mm; steel:0.5-0.8mm

Effective width: 300/400/500mm

Feeing width: about 472/575/675/mm

Material tension: G300MPa

Machine Components

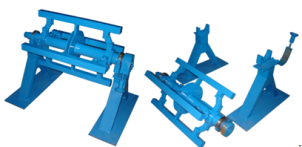

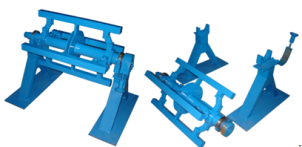

1.Manual decoiler: one unit 3 ton

2. Forming Machine: one set

Motor driving, Chain/Sprocket transmission; about 14step to form;

Rollers manufactured from high quality 40Cr, fine polished, heat treatment, hard Chrome Coated.

Shafts Diameter: ф75mm, Precision Machined

Main motor: 5.5KW, Frequency speed control

Forming speed: Approx.22m/min(not including cutting)

With Pneumatic Feeding Guide Device: air compressor one unit, Cylinder and pneumatic control components

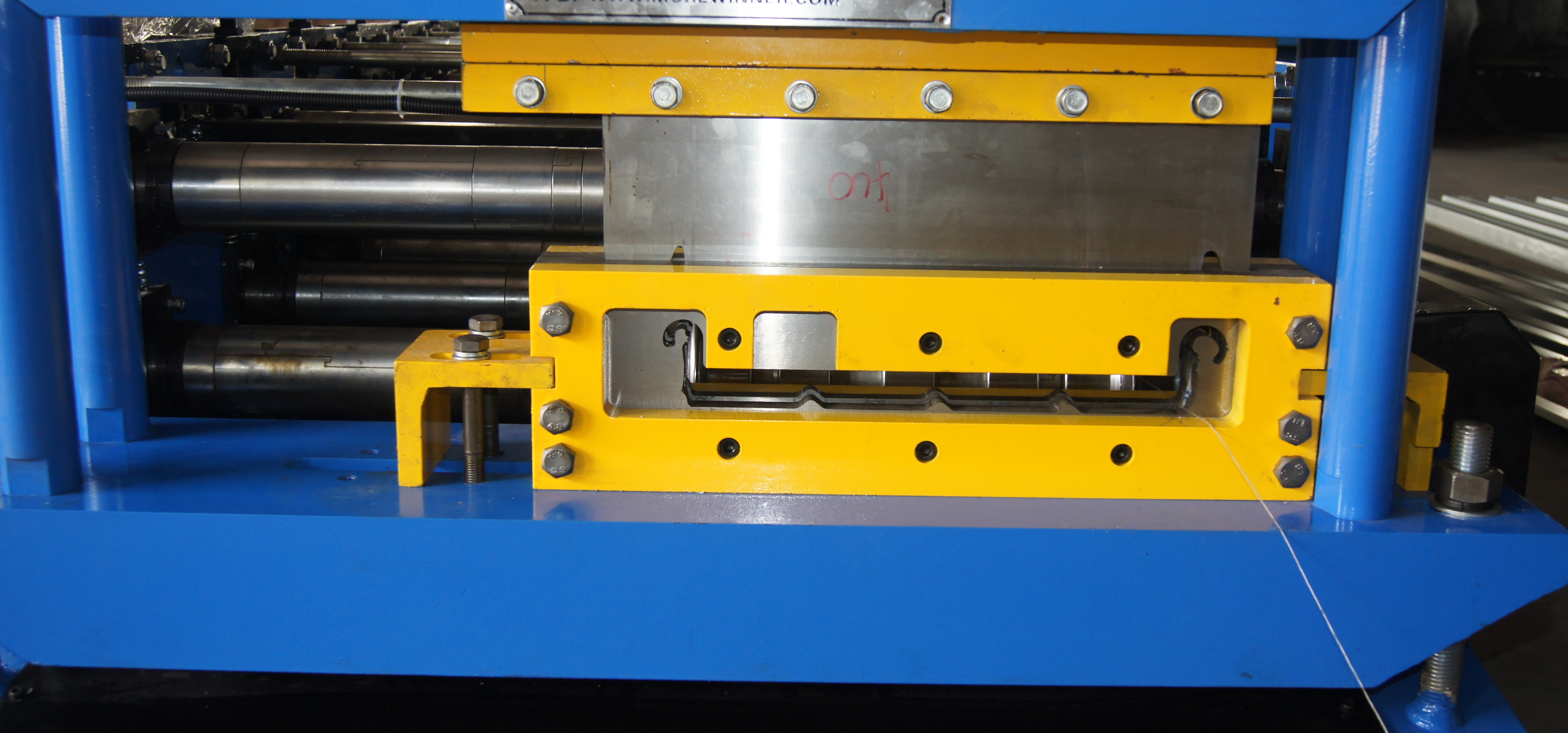

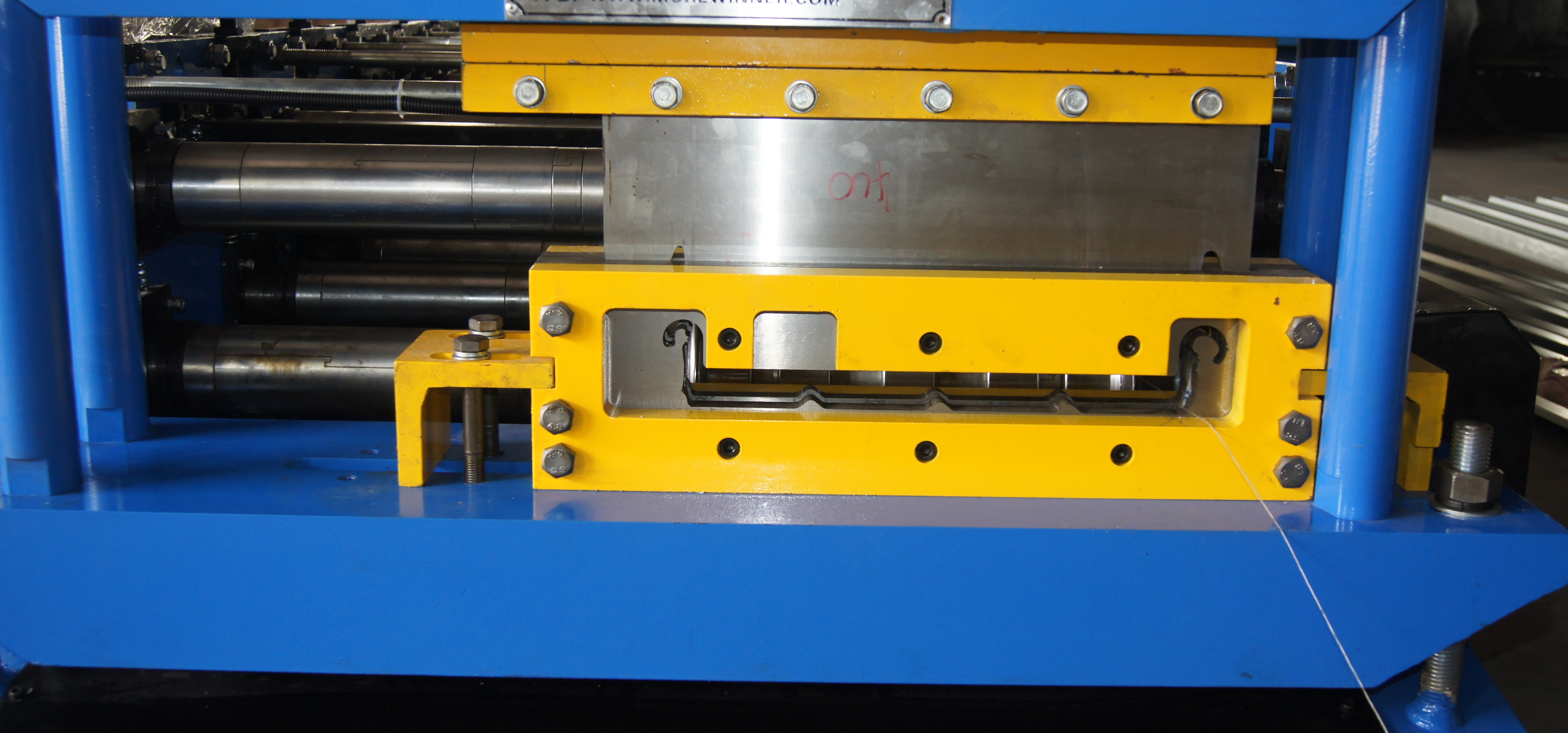

3. Hydraulic Cutting Device: one set

Stop to cut, post to cut, blanking to cut

Pump motor: 4.0KW; Cutting pressure: Max.12MPa

Cutting tool material: Cr12, Heat treatment HRC58-62,

2 pairs of cutting tool

----as reference

----as reference

4. Product Rack Un-powered, 4 units

----as reference

----as reference

5. PLC Control System: one set

Control the quantity and cutting length automatically

Combined with: PLC, Inverter,Touch Screen, Encoder, etc.

Cut-to-length tolerance≤±2.0 mm

6. Manual Edge-Locking Pincerstwo units (with extra cost US80.00/unit)

----as reference

7.Electric seaming machine One unit (with extra cost USD1500.00/unit)

----as reference

----as reference

With ONE 20’GP SECOND-HAND CONTAINER:

Rebuild by the seller make sure that container rebuilt is fasteness and safe electricity

II Cold Curving Machine Quotation for Profile YX65-300,400,500 and Taper

--as reference

--as reference

Curve machine specification: Gear driving

Rollers manufactured from high quality 40cr, CNC lathes, hard Chrome Coated

Shafts Diameter: ф75mm, Precision Machined

Main motor: 4 KW,

Server motor (Schneider Electric brand): 2KW,

Forming speed: Approx. 12m/min

The PLC Control System:

Control the quantity and cutting length automatically

Combined with: PLC, Inverter,Touch Screen, Encoder, etc.

Can curve positive arch and negative arch profile;

Straight sheet can be curved at one time, the taper sheet can be curved at two times.

Setting at the same time, the machine can curve 20 different positive and negative curving arch with different radius.

(for one-time curving, the minimum curved radius is convex curved 6 meters; concave curved 11 meters).

For example, the aluminum above 1.0mm thickness, and the material is soft, after two or three curving, the minimum radius of the convex arc can reach 2 meters below.

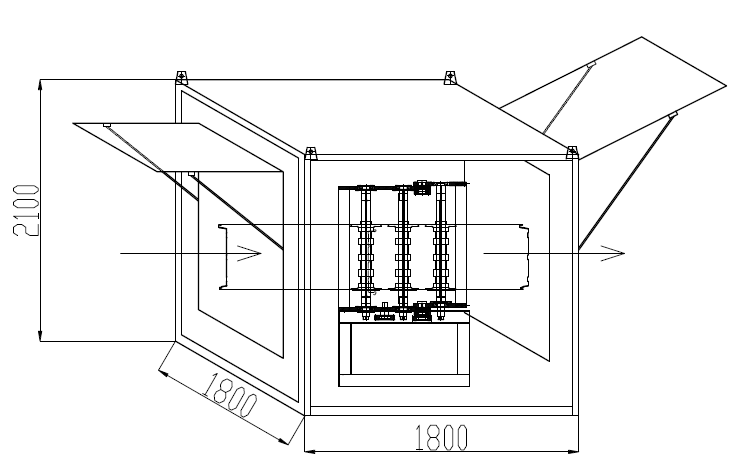

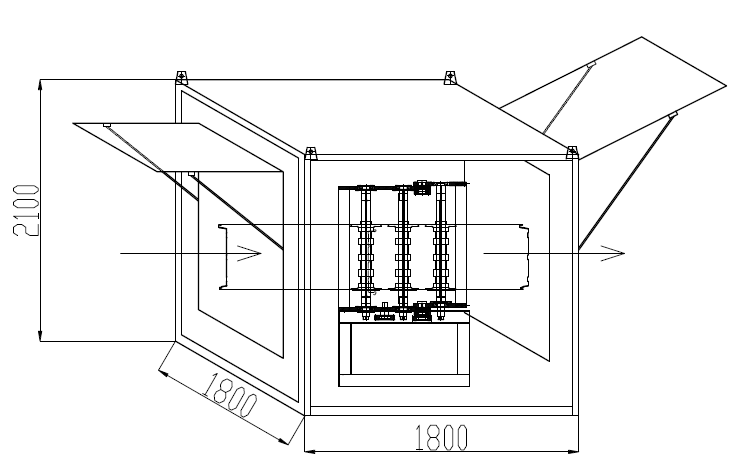

ADD CONTAINER: 1.8m×1.8m×2.1m

---as reference

---as reference

(Loading container photo for export)

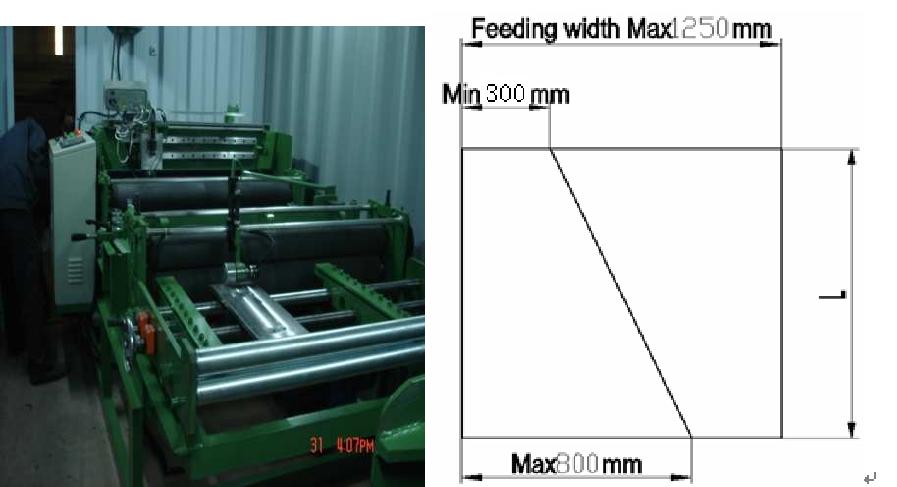

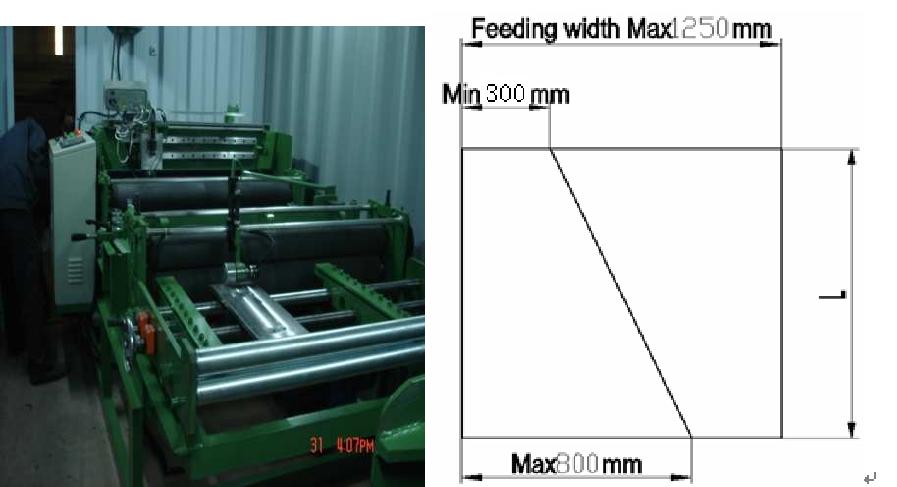

III SIMPLE ROLL FORMING MAHCINE FOR SLITTING

1.Manual De-coilerone unit

--as reference

2、Technical parameter:

The machine is used to make angle cuts from coil Thickness: 0.7mm – 1.2mm, aluminum,

0.5mm-0.8mm, steel Material Tension: G300MPa Cutting coil width: max.800mm Cutting coil width: min.300mm Cutting speed: Approx13m/min

Main motor =2.2KW×2units

Combined with: PLC, Inverter,Touch Screen, Encoder, etc.

With ONE 20’GP SECOND-HAND CONTAINER:

Rebuild by the seller make sure that container rebuilt is fasteness and safe electricity

----as reference

----as reference

----as reference

----as reference

----as reference

----as reference

--as reference

--as reference ---as reference

---as reference