Specification of

Roofing Panel Roll Forming Machine

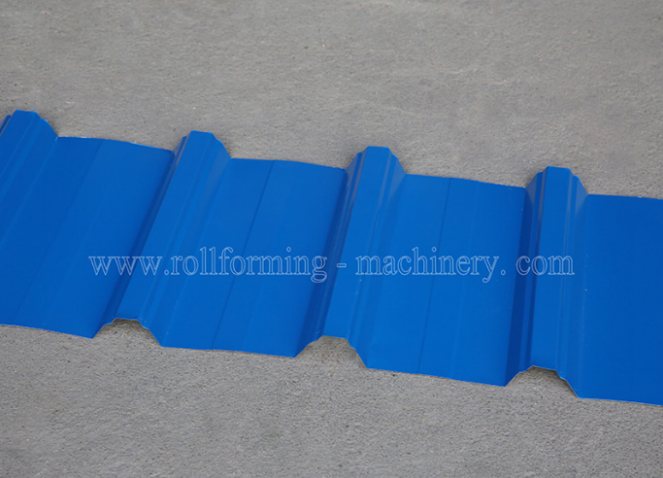

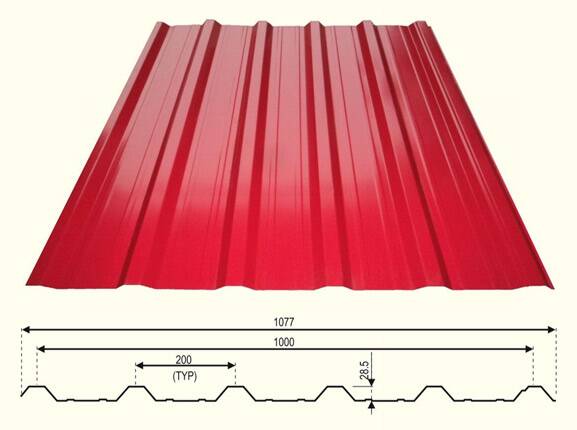

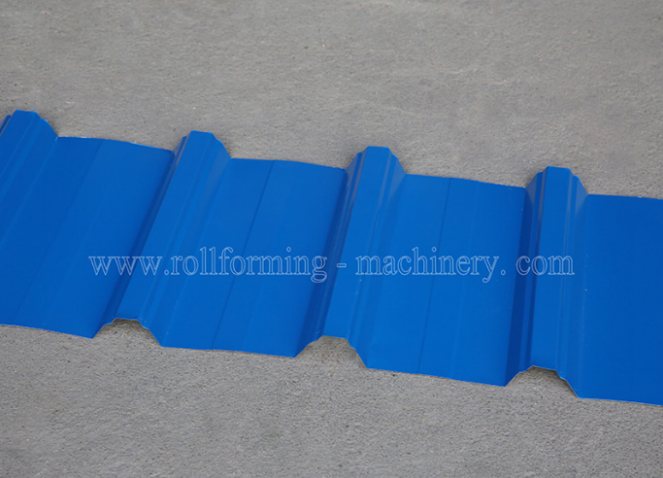

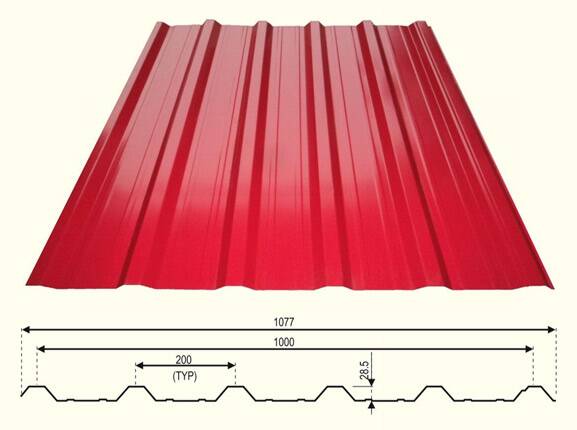

Profile Drawing

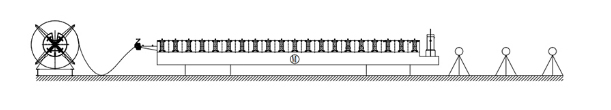

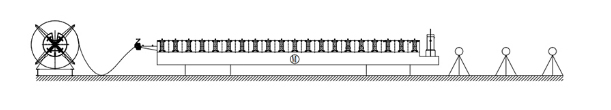

Flow Diagram

Decoiler→Manual Pre cutter→Guide feeding →Roll forming system→Hydraulic post cutter →Exit Rack

Material

Material Thickness:0.4-0.6mm Effective width: 1000mm

Applicable material:Prepainted Galvanised Steel(PPGI),PPGL,ACGL with yield strength 750Mpa

Effective width tolerance:±5mm The Wave spacing tolerance:±1mm

The wave height tolerance:±1mm Cut-to-length tolerance≤±1 mm

Machine Components

No. | Item | Number | Remark |

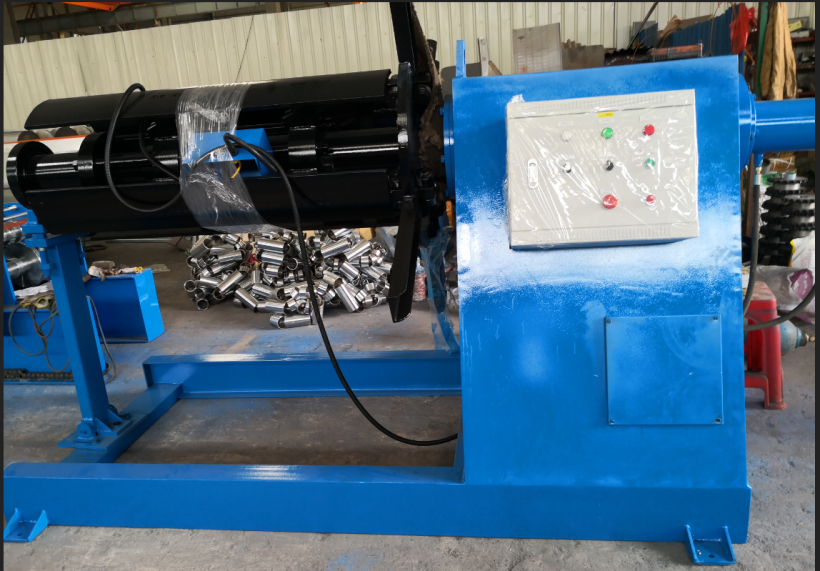

1 | Decoiler | 1 set | 7Ton Hydraulic Decoiler |

2 | Pre cutting device | 1 set | Manual |

3 | Guide feeding | 1 set |

|

4 | Roll forming machine | 1 set |

|

5 | Post cutting device | 1 set |

|

6 | Exit Rack | 3 sets | Easy to adjust |

7 | Hydraulic system | 1 set |

|

8 | PLC control system | 1 set |

|

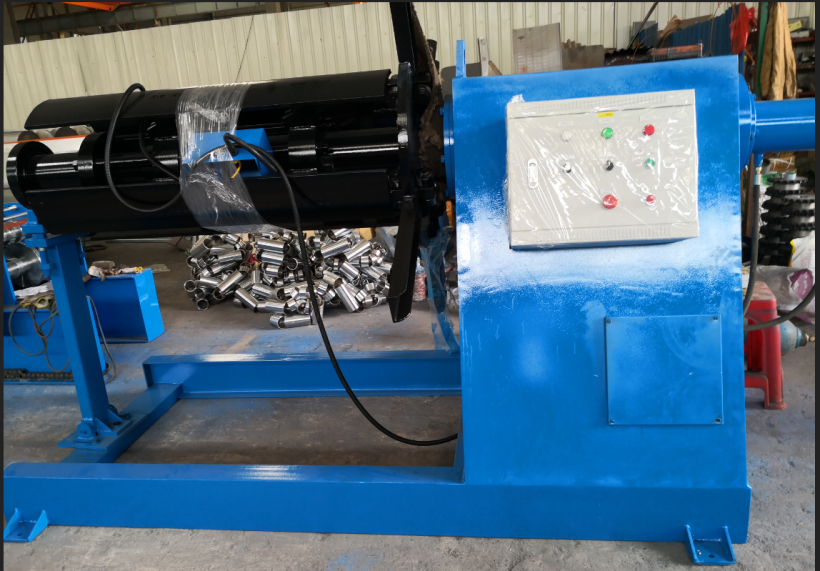

1) 7T hydraulic Decoiler: one set

2) Cold Rolling Mill:

★ Guide feeding device

★ Manual Pre cutter

★ Roll forming system

Roll forming system is composed of a machine frame, transmission parts and forming roller group etc.

1) body frame made from H450 type steel by welding, side board thickness: 18mm

2)Roller adopts 45#, after forging, precision CNC machining, Heat treatment. Part of the roller is equipped with bearings.

3)The roller axle adopts 45# steel after quenching and tempering treatment,Coated with thickness 0.04mm(for longer life and anti-rust),

4)The lower roller group is rotated by the chain and motor,parts of the upper and lower rollers are driven by a gear.

5)Adjusting the upper and lower roller gap by hand screw,in order to adapt to the plate with different thickness

6)Chain: ZIQIANG (by China TOP 1 brand DONGHUA Group)

7)Shaft diameter:φ80/95mm,precision machined

8)All the screw bolts with grade 8.8(cheap factories use low grade 4.8) to ensure fix the machine structure tightly and long life during the machine long time running.

9)Motor driving, Gear chain transmission,20 steps to form

10)Servo motor 7.5KW, Frequency speed control Forming speed approx. 20-25m/min

★ Hydraulic Post-Cutting system

1) Hydraulic motor: 4KW, Hydraulic pressure range: 0-16Mpa,Cutting time :2s

2) Cut after roll forming, stop to cut, no blanking; Cutting tool material adopts MOLD STEEL Cr12MOV (=SKD11 steel,with at least one million times of cutting life)

3) The cutting power is provided by the main engine hydraulic station.

★ PLC control system

1)Using PLC control technology, variable frequency speed regulation technology, to realize the automatic production of the whole machine.

2)System provides a friendly man-machine interface,can set the batch, the length of the work piece, quantity, etc.

3)Operate mode:Touch screen input + button.

4)Encoder count,with counting numbers and counting length function.

★ Exit Rack

Three units,Un-powered,for easy move.

★ Product show