- Home

- Machines

-

- Metal Roofing Roll Forming Machine

- Purlin Roll Forming Machine

- Metal Deck Roll Forming Machine

- Double Deck Roll Forming Machine

- Stud and Track Roll Forming Machine

- Roof Panel Crimping Machine

- Gutter Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Window Roll Forming Machine

- Door Roll Forming Machine

- Ceiling Roll Forming Machine

- Pipe Roll Forming Machine

- Scaffolding Roll Forming Machine

- Tube Roll Forming Machine

-

-

-

-

-

-

-

-

-

-

-

-

- About BMS

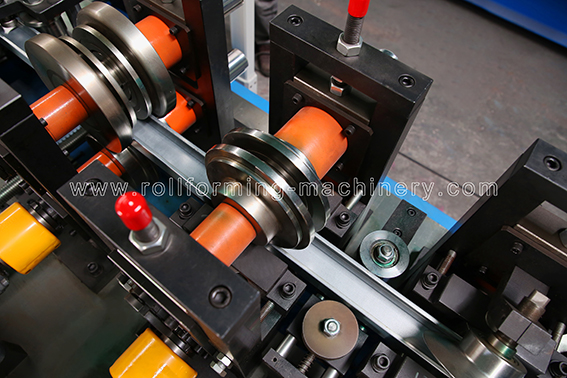

- Purlin Roll Forming Machine

- Service

- Industries

- Support&Video

- News

- Contact BMS

close

Choose Your Site

Global

Social Media

- Home

- Machines

-

- Metal Roofing Roll Forming Machine

- Purlin Roll Forming Machine

- Metal Deck Roll Forming Machine

- Double Deck Roll Forming Machine

- Stud and Track Roll Forming Machine

- Roof Panel Crimping Machine

- Gutter Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Window Roll Forming Machine

- Door Roll Forming Machine

- Ceiling Roll Forming Machine

- Pipe Roll Forming Machine

- Scaffolding Roll Forming Machine

- Tube Roll Forming Machine

-

-

-

-

-

-

-

-

-

-

-

-

- About BMS

- Purlin Roll Forming Machine

- Service

- Industries

- Support&Video

- News

- Contact BMS